Jacket dismantling ship and dismantling method

A jacket and hull technology, applied in ship construction, ship accessories, ship parts, etc., can solve the problems of high construction and use cost, difficulty, complex structure of ballast control system, etc., achieve good adaptability, reduce construction cost, Risk reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

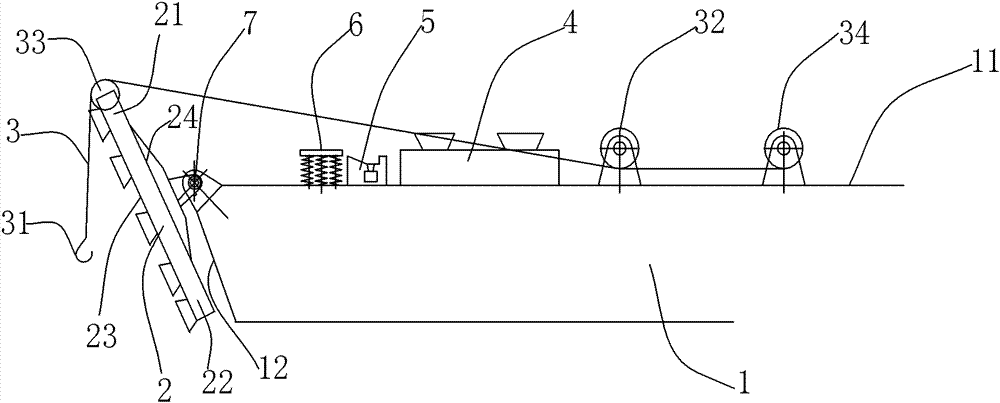

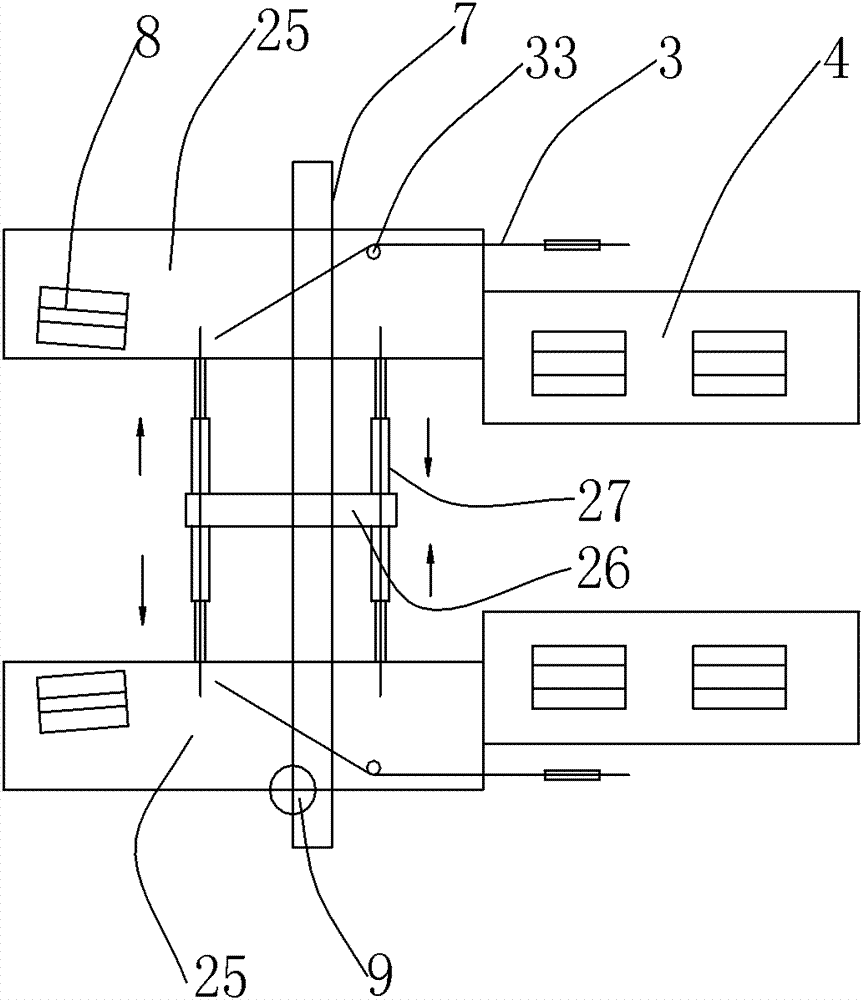

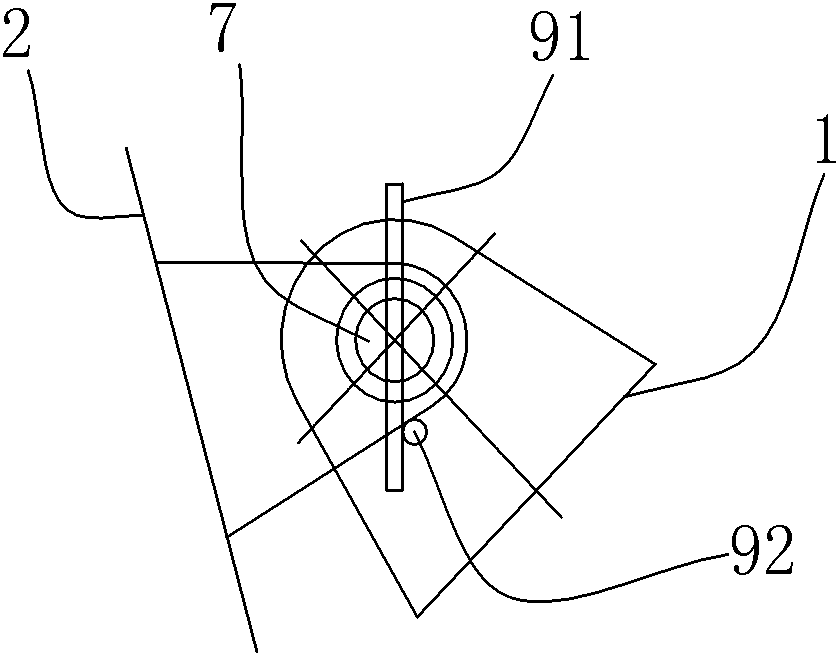

[0038] Such as figure 1 As shown, a jacket dismantling vessel of the present invention includes a hull 1 having a hull deck 11 and an inclined hull end surface 12 . A horizontal roller 7 is installed at the junction of the hull deck 11 and the hull end face 12 . Turning plate 2 comprises an upper end 21, lower end 22, a front 23 and a back 24, and turning plate back 24 is rotatably hinged on the roller shaft 7, because the hinge position of turning plate 2 and roller shaft 7 is closer to its upper end 21 , so in the initial state, under the action of its own weight, the flap 2 will naturally turn over on the hull end face 12 (that is, it is roughly parallel to the hull end face 12); but under the action of external force, the flap 2 can Turn around the roller 7 between the hull deck 11 and the hull end face 12, the turning angle α o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com