High temperature melt discharge pipe and smelting furnace with same

A discharge pipe and melt technology, applied to furnaces, crucible furnaces, furnace components, etc., can solve problems such as unsafety, shortened service life, furnace wall oxidation, etc., and achieve the effect of reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

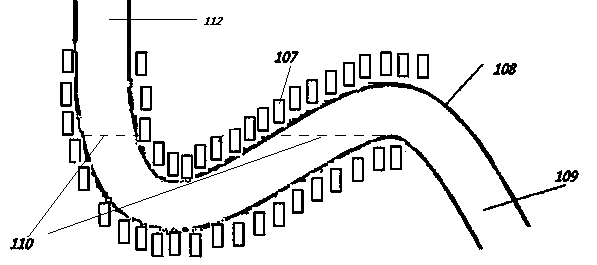

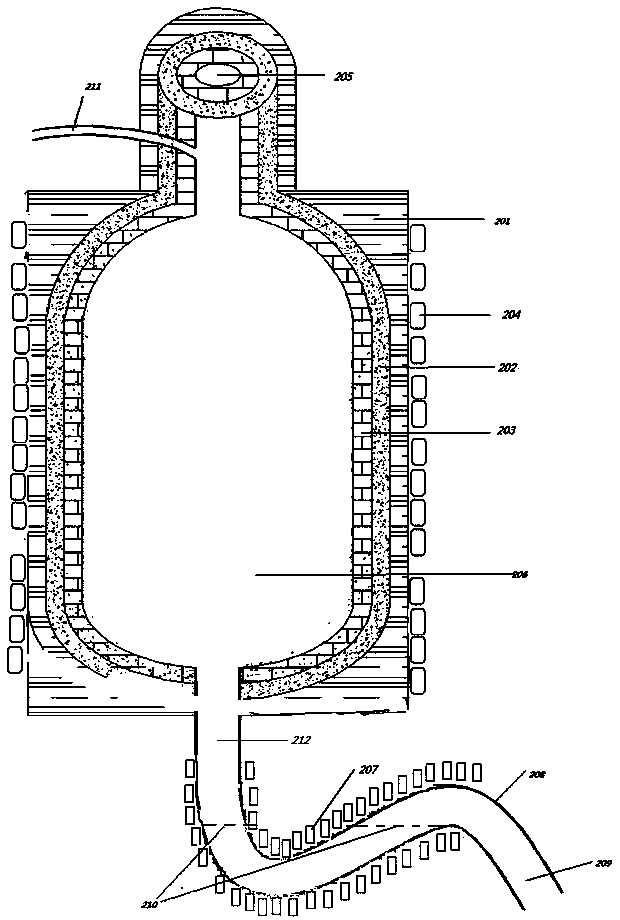

[0018] Embodiment 1: A discharge pipe for high-temperature melt, including a pipe with a submerged water bend structure, and an intermediate frequency power supply coil for heating wound outside the pipe wall; the pipe wall is made of high-temperature-resistant materials; Intermediate frequency power supply coil 107; one end of the tubular structure communicates with the furnace chamber through the bottom and / or lower part of the smelting furnace body; at the beginning of smelting, the melt flows into the liquid surface line 110 of the submerged water bend, deposits, cools and solidifies, and then blocks the pipeline. When the melt in the furnace cavity needs to be discharged from the furnace cavity, power is transmitted to the intermediate frequency power supply coil 107 wound on the pipeline, so that the smelting material in the submerged water bend is melted rapidly, and the melt in the furnace cavity is discharged from the pipeline, and then the valve is closed. The interme...

Embodiment 2

[0019] Embodiment 2: The high-temperature-resistant materials constituting the pipe walls 108 and 208 can be selected according to the smelting temperature, such as zirconia, aluminum oxide, magnesium oxide, graphite, heat-resistant steel, corundum and other materials that can withstand the corresponding temperature. The melting point of lead is 327.5 degrees Celsius, and the pipe wall material can be heat-resistant steel. When producing high-titanium slag, the melting point of titanium dioxide is about 1800 degrees Celsius, the highest melting point of iron is 1535 degrees Celsius, and the zirconia tube can withstand a temperature of 2200 degrees Celsius. When titanium slag is used, the pipe wall material is preferably zirconia.

Embodiment 3

[0020] Embodiment 3: The outer layer 201 of the furnace wall is made of high-temperature-resistant ceramic fiber board, the middle layer 202 of the furnace wall is made of aluminum oxide poured on aluminum, and the inner layer 203 of the furnace wall is made of zirconia.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com