Appearance check device and appearance check method

An appearance inspection device and appearance inspection technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as unrealistic, unclear judgment, and not necessarily guaranteed inspection quality, so as to ensure inspection quality, ensure inspection accuracy, Effects of preventing storage errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

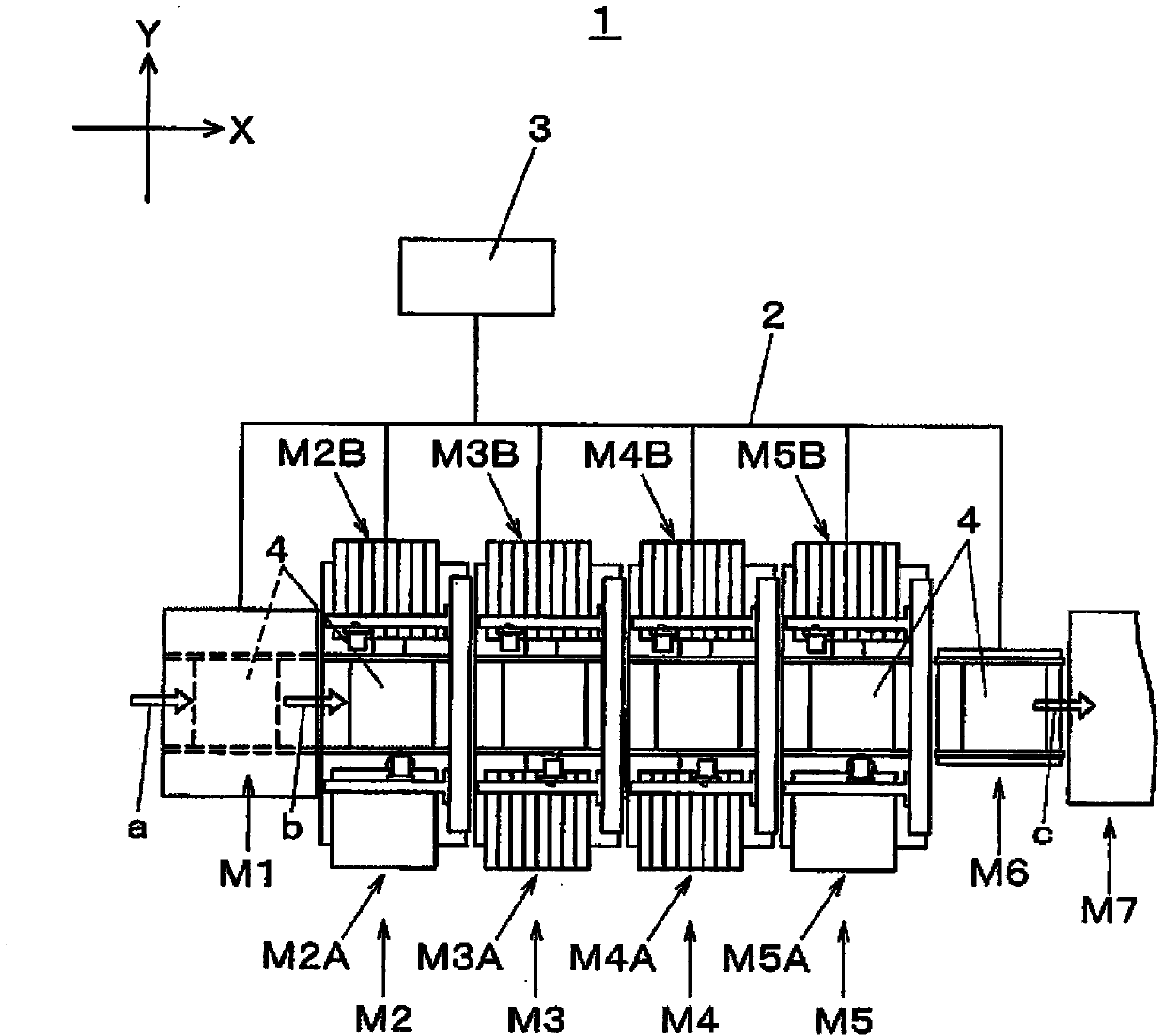

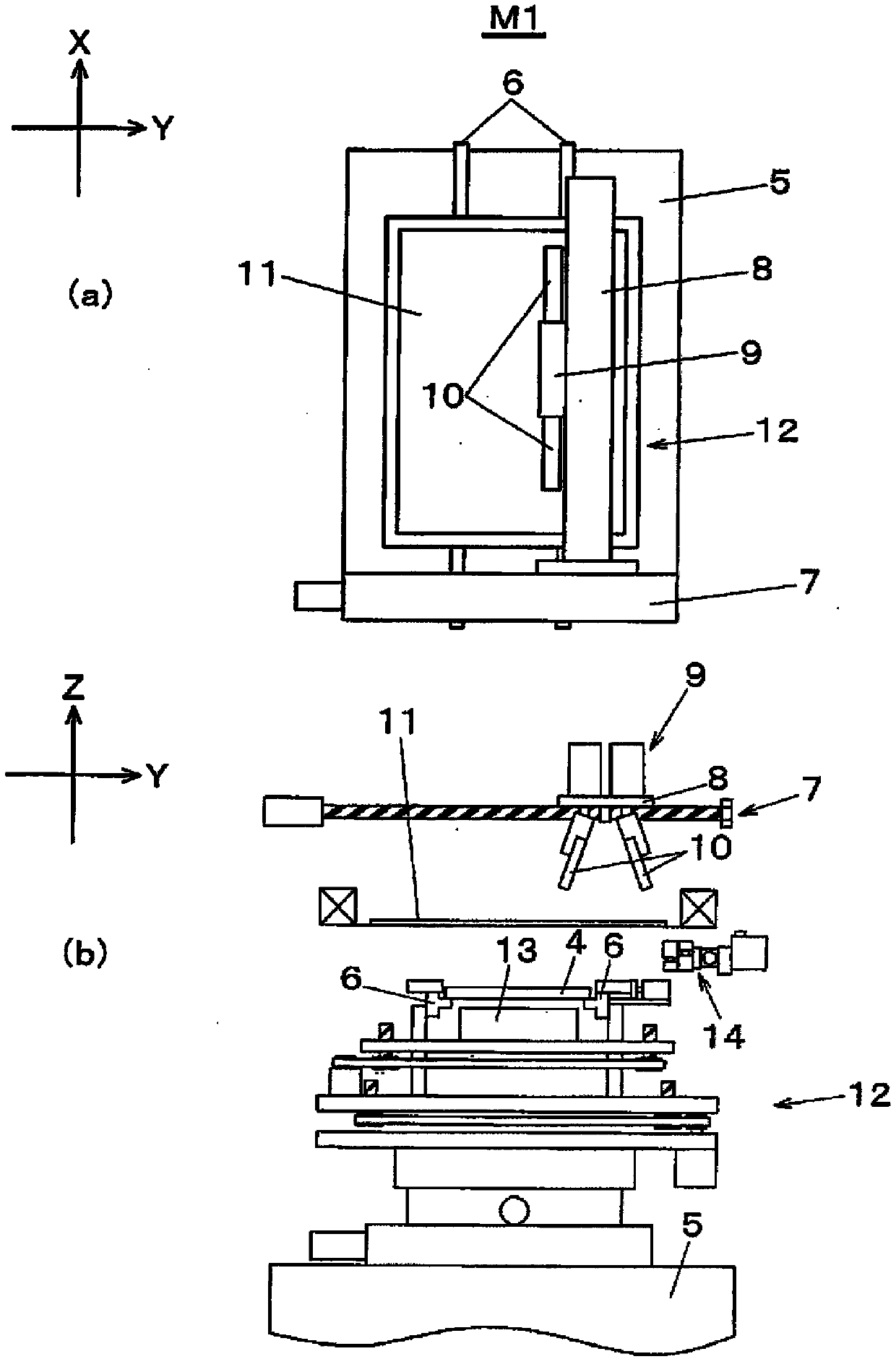

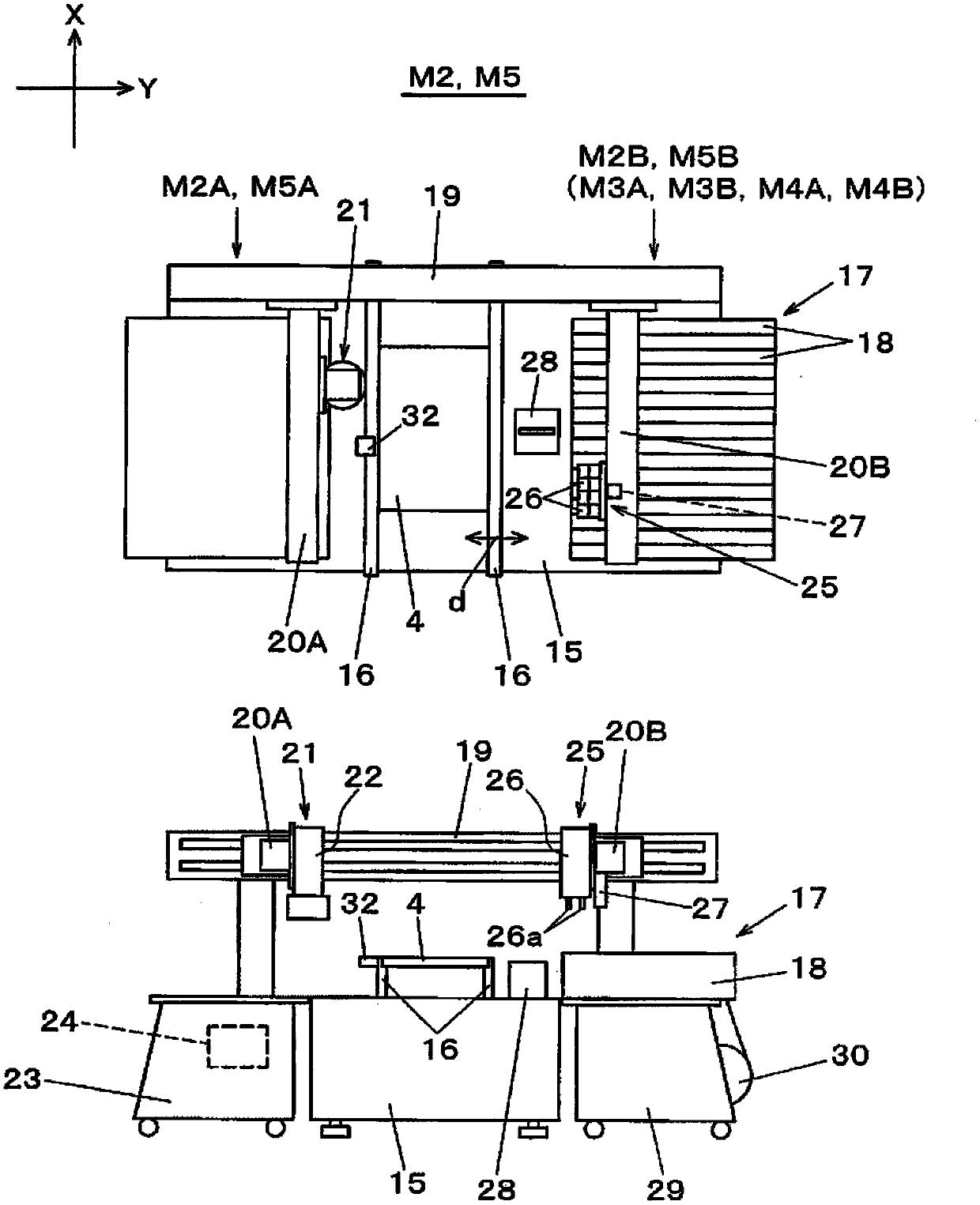

[0056] Next, embodiments of the present invention will be described with reference to the drawings. First, refer to figure 1 An electronic component mounting system 1 that manufactures a mounted substrate by mounting electronic components on a substrate will be described. exist figure 1 In the electronic component mounting system 1, each device of the printing device M1, the inspection and mounting device M2, the electronic component mounting device M3, M4, the inspection and mounting device M5, the substrate transfer device M6 and the reflow soldering device M7 is moved along the substrate conveying direction ( X direction) The main body is the electronic component installation line formed by linking. Each device constituting the electronic component mounting line is connected through a communication network 2 and controlled by a host device 3 having a management computer function. In this way, transmission of control commands from the host system and exchange of signals b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com