Production resource pushing system based on wireless intelligent network

A technology of intelligent network and production resources, applied in the direction of energy-saving ICT, comprehensive factory control, sustainable building, etc., can solve the problem of wireless network node increase in communication stability, etc., to solve the problem of communication stability, realize power consumption, reduce system cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

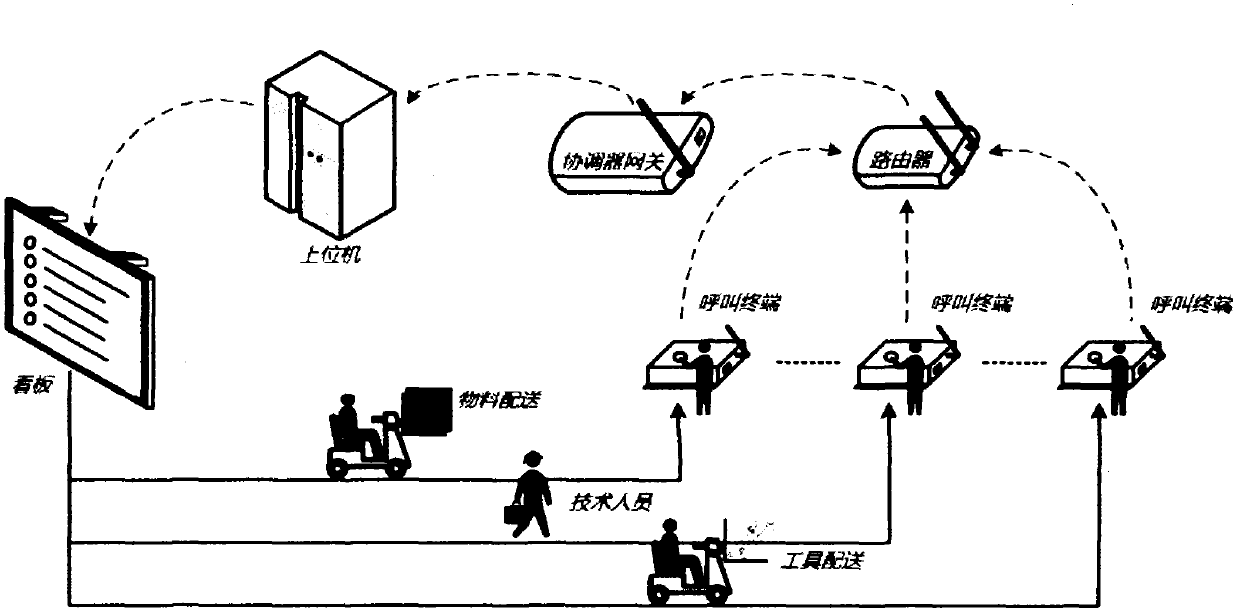

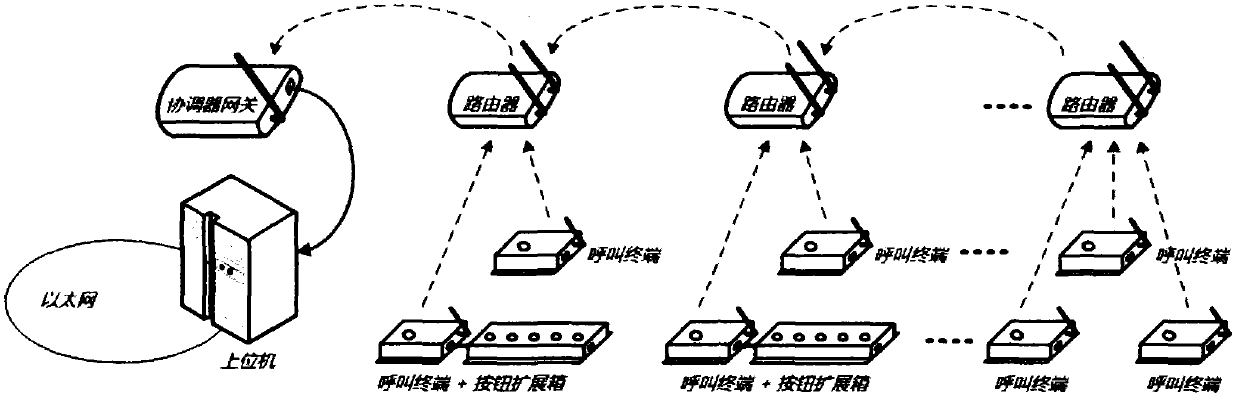

[0045] figure 1 It is a schematic diagram of an embodiment of the present invention. Such as figure 1 As shown, the production resource pulling system includes 3 call terminals, 1 router, 1 coordinator gateway and 1 upper computer.

[0046] According to the specific needs of the factory, call terminals are installed at positions that are prone to material shortages, equipment failures, and tool replacements to issue material request calls, quality request calls, and tool request calls. According to the layout of the workstations and the ability of each router to connect to the network nodes, it is determined that the installation position of the router is located above the workshop of the covered workstations. Determine the installation location of the coordinator gateway according to the location distribution of the deployed routers and the location of the host computer in the factory.

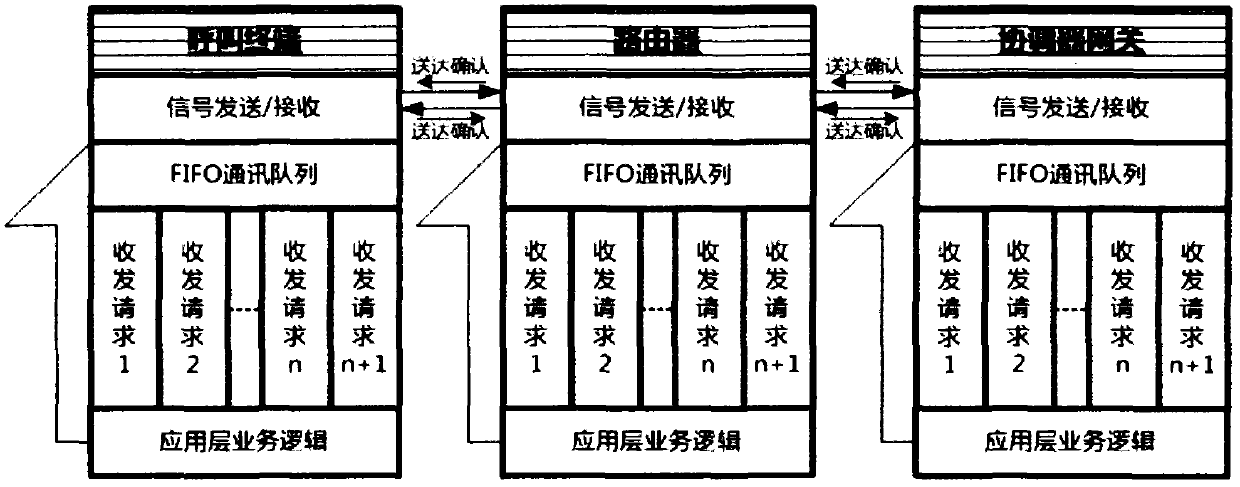

[0047] After the above-mentioned call terminal, router, and coordinator gateway are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com