Efficient special cage for commercial rabbits

A technology for cages and products, which is applied in the field of high-efficiency commercial rabbit cages, can solve the problems of low production efficiency, serious mutual pollution, and inconvenient operation, so as to avoid water inflow and pollution, reduce workload, reduce labor intensity and The effect of operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are specifically described below in conjunction with the accompanying drawings:

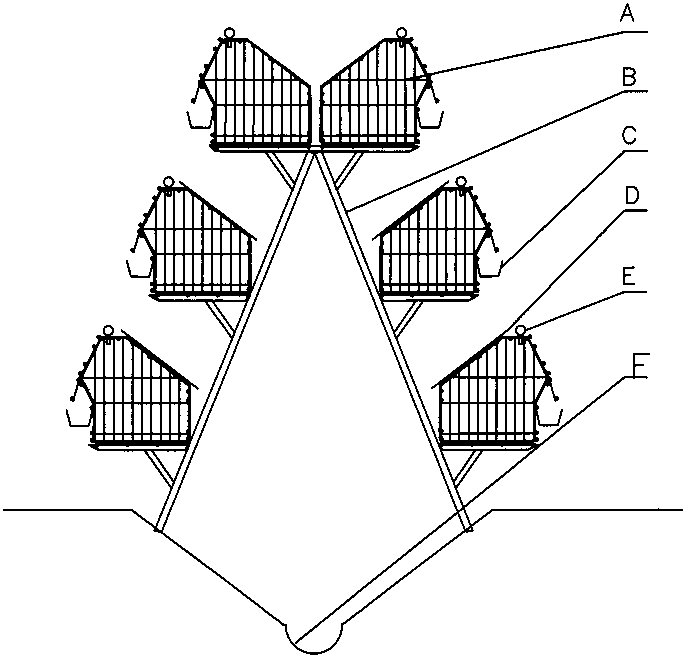

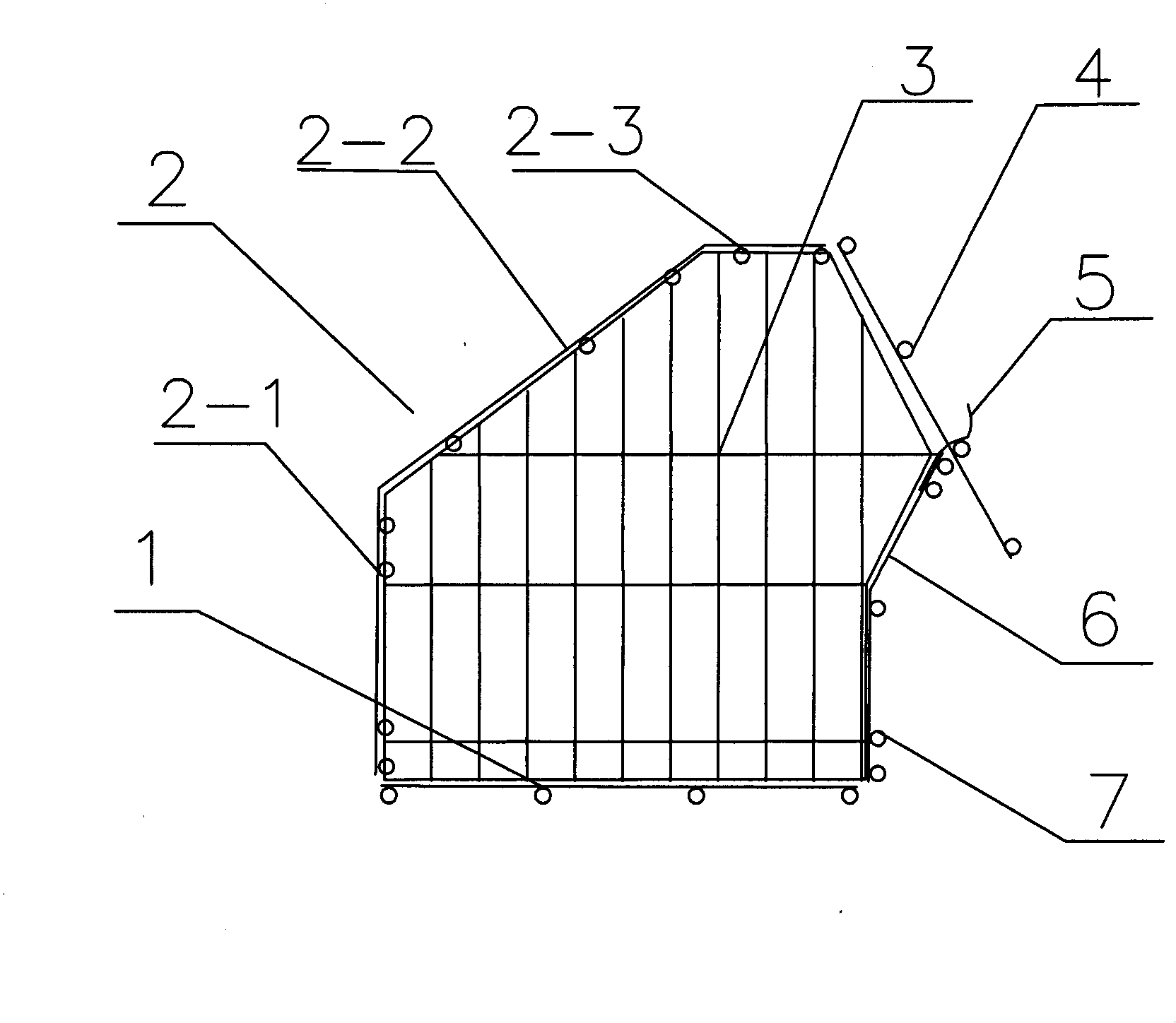

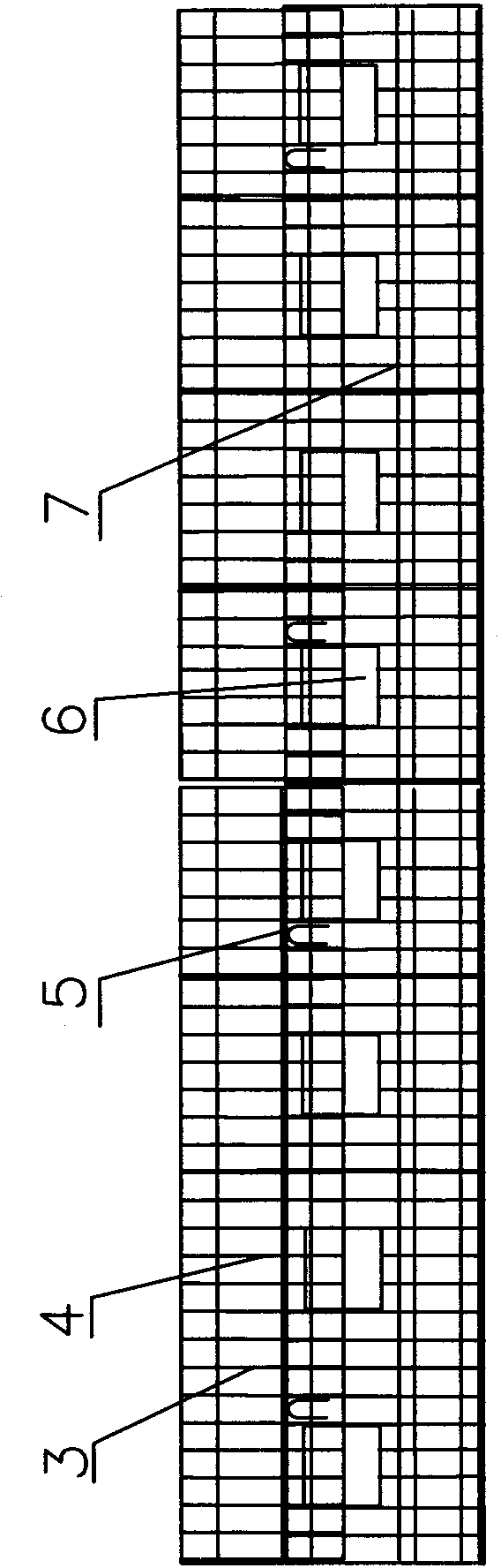

[0038] See Figure 1-3 , the specific structure is as follows: the single cage A of the present invention is formed by connecting and combining the meshes welded by wires through wires, and each mesh is the bottom sheet 1, the rear sheet 2, the end sheet 3, the cage door 4 and the front sheet. slice 7. Wherein, there is feeding opening 6 on the front piece 7, and feeding opening 6 bends forward, has not only made things convenient for the rabbit's feeding, but also increased self strength, and enlarged the opening size at the cage door place again simultaneously. See figure 2 , The cage door 4 is obliquely installed on the upper part of the front of the cage and extends downwards; the front piece 7 is provided with a cage door hook 5. The back sheet 2 is composed of a vertical sheet 2-1, an oblique sheet 2-2 and an upper sheet 2-3. See figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com