Surface protection film and optical component attached therewith

A technology for surface protection films and optical components, which is applied to optical components, optics, film/sheet adhesives, etc., can solve problems such as circuit component damage and liquid crystal molecular orientation damage, and achieve improved production performance and yield , no aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

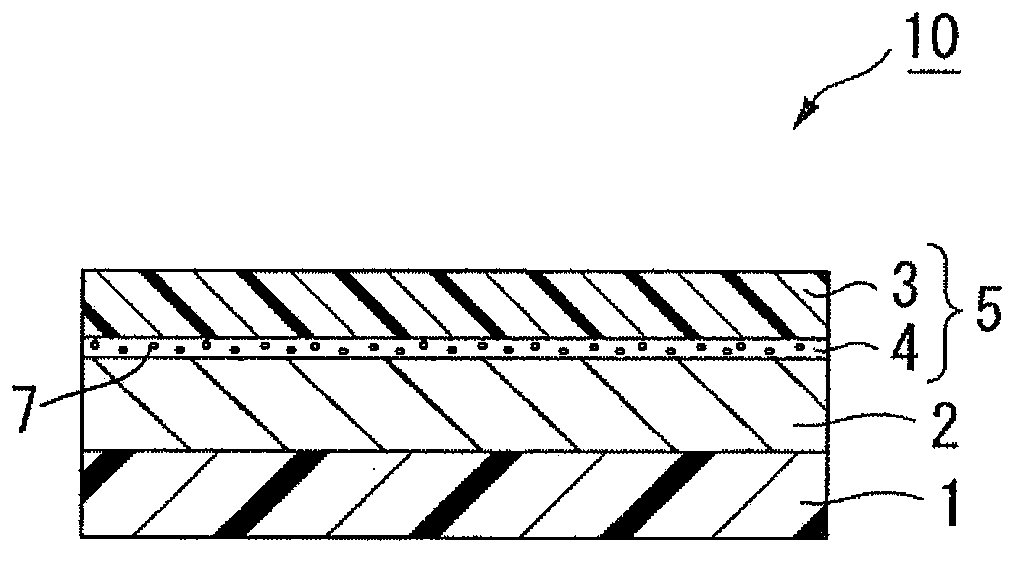

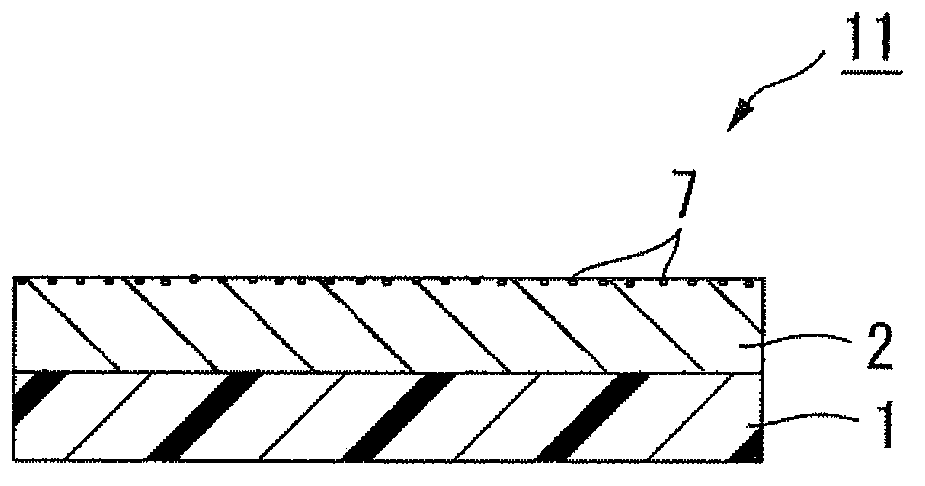

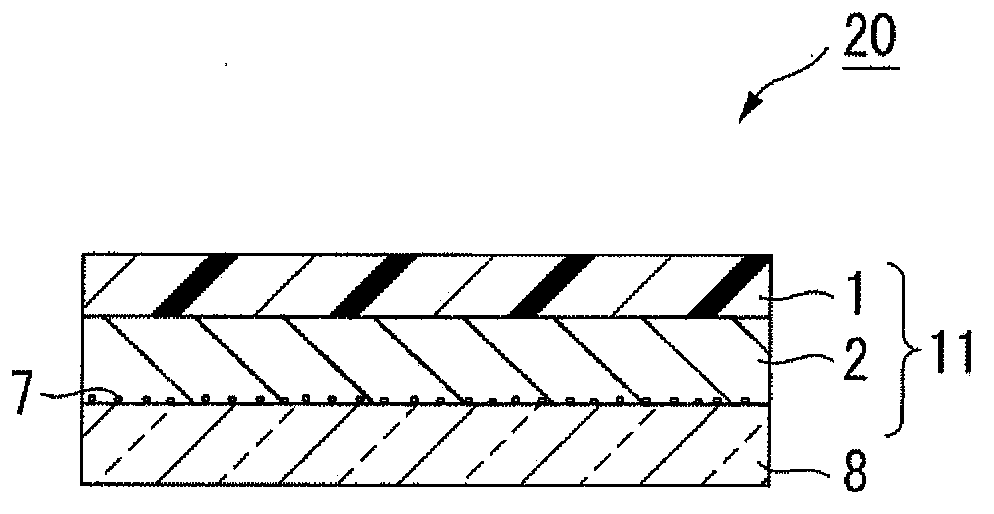

Image

Examples

Embodiment 1)

[0087] (Preparation of Adhesive Composition)

[0088] Add 90 parts by weight of 2-ethylhexyl acrylate, 10 parts by weight of methoxypolyethylene glycol (400) monomethacrylate, acrylic acid 3 parts by weight of 2-hydroxyethyl ester, 0.2 parts by weight of 2,2'-azobisisobutyronitrile as a polymerization initiator, and 154 parts by weight of ethyl acetate were heated up to 65° C. while stirring the content while introducing nitrogen gas. Furthermore, a polymerization reaction was carried out at a temperature of about 65° C. for 6 hours to obtain the adhesive composition of Example 1 (40% solid content) formed of an acrylic polymer containing a polyoxyalkylene group.

[0089] (Preparation of surface protection film)

[0090] 3 parts by weight of addition reaction silicone (manufactured by Toray Dow Corning Co., Ltd., trade name: SRX-345) and polyether-modified silicone (manufactured by Toray Dow Corning Co., Ltd., trade name: SH8400) 0.1 parts by weight, 97 parts by weight of a ...

Embodiment 2)

[0092] 100 parts by weight of the adhesive composition of Example 1 and 0.1 part by weight of lithium perchlorate as an antistatic agent were stirred and mixed to prepare the adhesive composition of Example 2 containing an antistatic agent.

[0093] Except having used the adhesive composition of Example 2 instead of the adhesive composition of Example 1, it carried out similarly to Example 1, and obtained the surface protection film of Example 2.

Embodiment 3)

[0095] Stir and mix 100 parts by weight of the adhesive composition of Example 1 and 1.5 parts by weight of lithium bis(trifluoromethanesulfonyl)imide as an antistatic agent to prepare the adhesive combination of Example 3 with an antistatic agent thing.

[0096] Except having used the adhesive composition of Example 3 instead of the adhesive composition of Example 1, it carried out similarly to Example 1, and obtained the surface protection film of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com