Infrared Heating Processing Technology of Rubber Hose

A rubber hose and infrared heating technology, applied in the field of new technology, can solve the physical and mental health damage of product processing personnel, consumer health hazards, environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

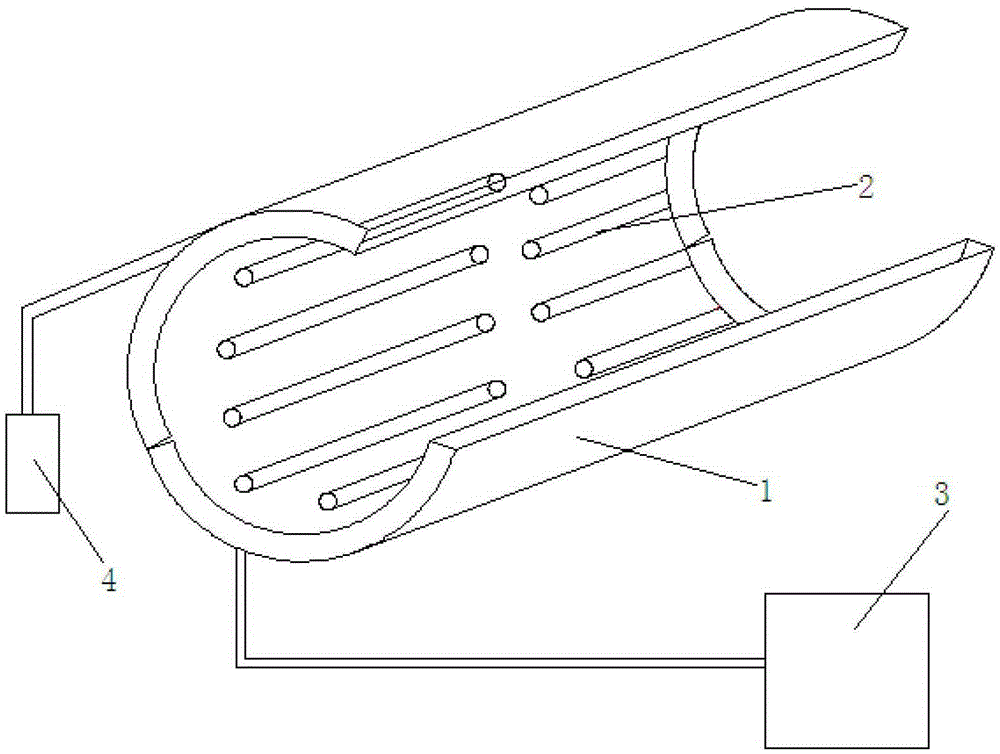

[0010] Refer to the attached figure, the infrared heating process of the rubber hose, adding adhesive to the compounded rubber of the inner and outer rubber layers of the rubber hose 1, the inner diameter of the rubber hose 1 is φ3.5mm-φ50mm, and the inner rubber of the rubber hose 1 The layer is extruded through a braiding machine or a knitting machine to coat the tube blank with a reinforcing layer, and then heat treatment by an infrared heating device, and the temperature rises to activate the adhesive in the rubber compound. The infrared heating device is composed of 12 electric heating tubes 2 and power control unit 3. Products of different specifications have different speeds through the infrared heating device. The speed of products with different pipe diameters passing through the infrared heating device can be adjusted to 5m / min~10m / min, and then adjust the heating tube speed. Power, the heating power is controlled at 65% to 70%, the heating temperature is controlled a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com