Shield waste mud gel breaker as well as use method and application thereof

A technology of waste mud and gel breaker, which is applied in the fields of chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc. It can solve the difficulties in the treatment of waste mud of shield tunneling, the inability to reuse the waste mud of shield tunneling, environmental issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 of the present invention provides a shield waste mud shredder comprising a component of mass: waste shield mud (aquifer fraction 80%), 0.008 sulfate, iron sulfate, iron chloride 0.004 copies, 0.004 plaster powder, 0.002 industrial antifoaming agents, 0.002 sodium industrial grade carbonate.

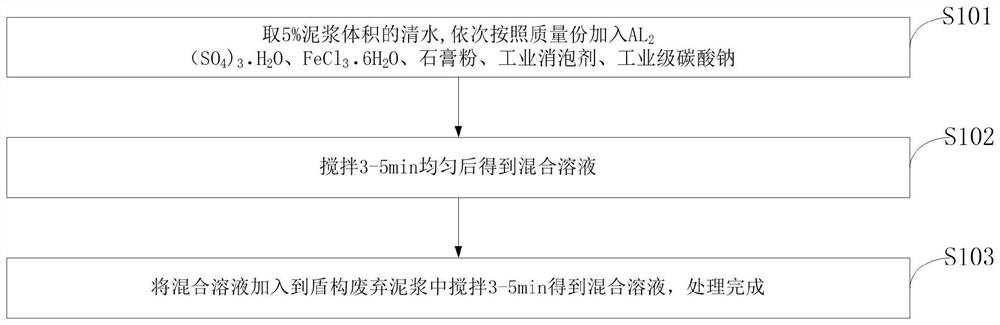

[0035] Take 5% of the water volume of water, and add Al in accordance with quality parts. 2 (SO 4 ) 3 · 18h 2 O, FECL 3 · 6h 2 O, gypsum powder, industrial antifoaming agent, industrial grade carbonate agitate and mixed with mixed solution to give the mixed solution to the shield waste mud stirring 3-5 min to obtain a mixed solution, and the treatment is completed.

Embodiment 2

[0037] Example 2 of the present invention provides a shield waste mud shredder comprising a component of mass: waste shield mud (aqueous mass fraction 80%), 0.008 sulfate, ferricide 0.007 parts, 0.009 gypsum powder, 0.002 industrial antifoaming agents, 0.002 sodium carbonate.

[0038] The use of the shield waste mud shredder is the same as the method of using the shield waste mud shredder in Example 1.

Embodiment 3

[0040]Example 3 of the present invention provides a shield waste mud shroud, including components such as a mass component: abandoned shield mud (aquifer fraction 80%), 0.008 parts of aluminum sulfate, iron chloride 0.01 copies, 0.01 plaster powder, 0.03 industrial antifoaming agents, 0.003 sodium carbonate.

[0041] The use of the shield waste mud shredder is the same as the method of using the shield waste mud shredder in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com