Method of transporting liquid drops by micro-fluidic chip

A microfluidic chip and droplet technology, applied in the field of biomedicine, can solve the problems of low reusability, easy blockage of micropipes, complicated manufacturing process of micropipes, etc., and achieve the effect of reducing the driving voltage of the chip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiment of the present invention discloses a method for transporting droplets by a microfluidic chip, including:

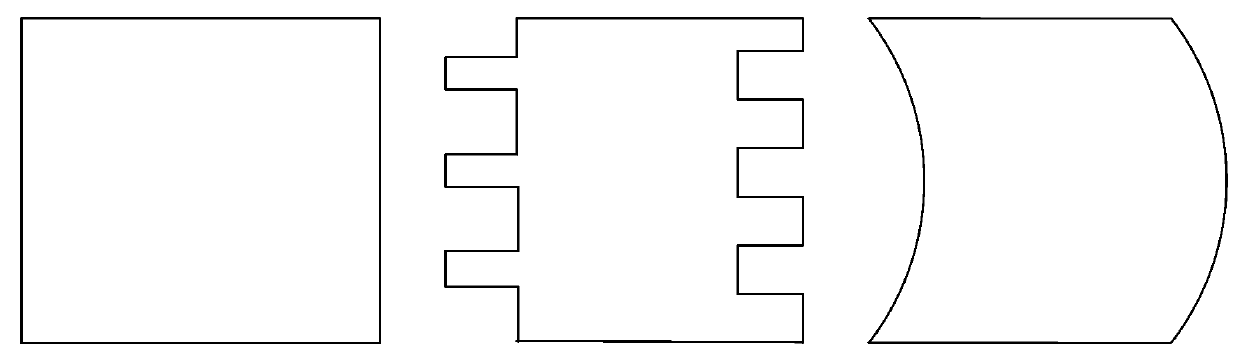

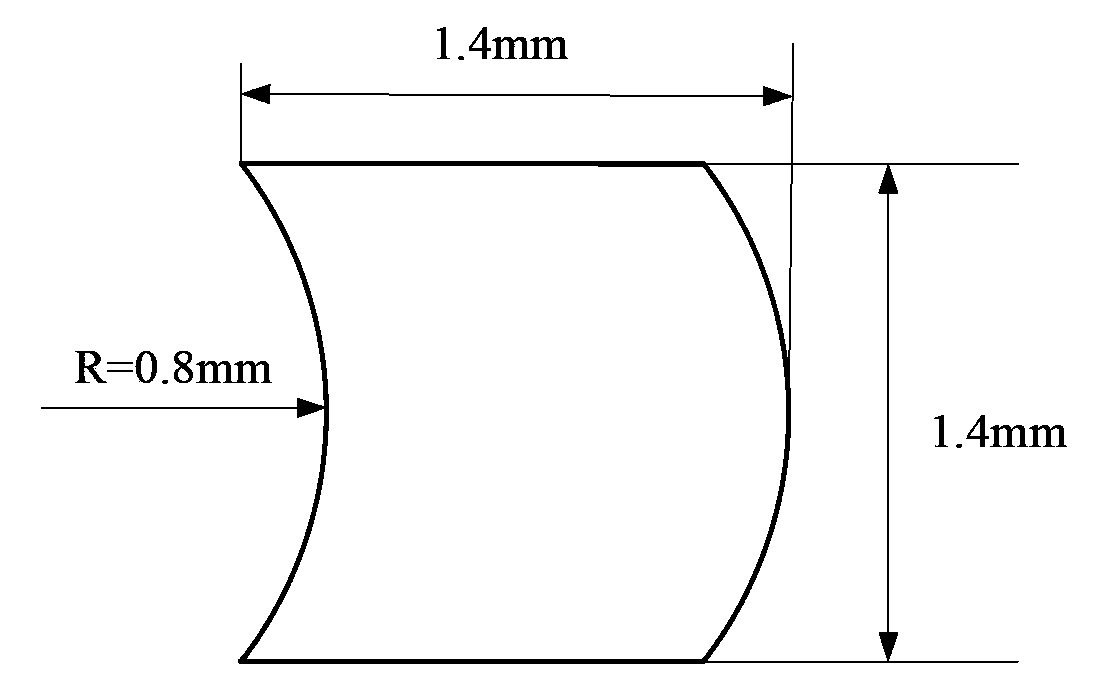

[0035] s1. Provide a microfluidic chip. The microfluidic chip includes drive electrodes arranged in an array. The drive electrodes are half-moon-shaped. In the droplet transport direction, one edge of the drive electrodes is a convex arc shape, the other side edge is a concave arc shape, and the concavity and convexity between adjacent electrodes are opposite;

[0036] s2. Applying a potential of 32V to 60V between adjacent driving electrodes to drive the movement of the liquid droplets on the driving electrodes.

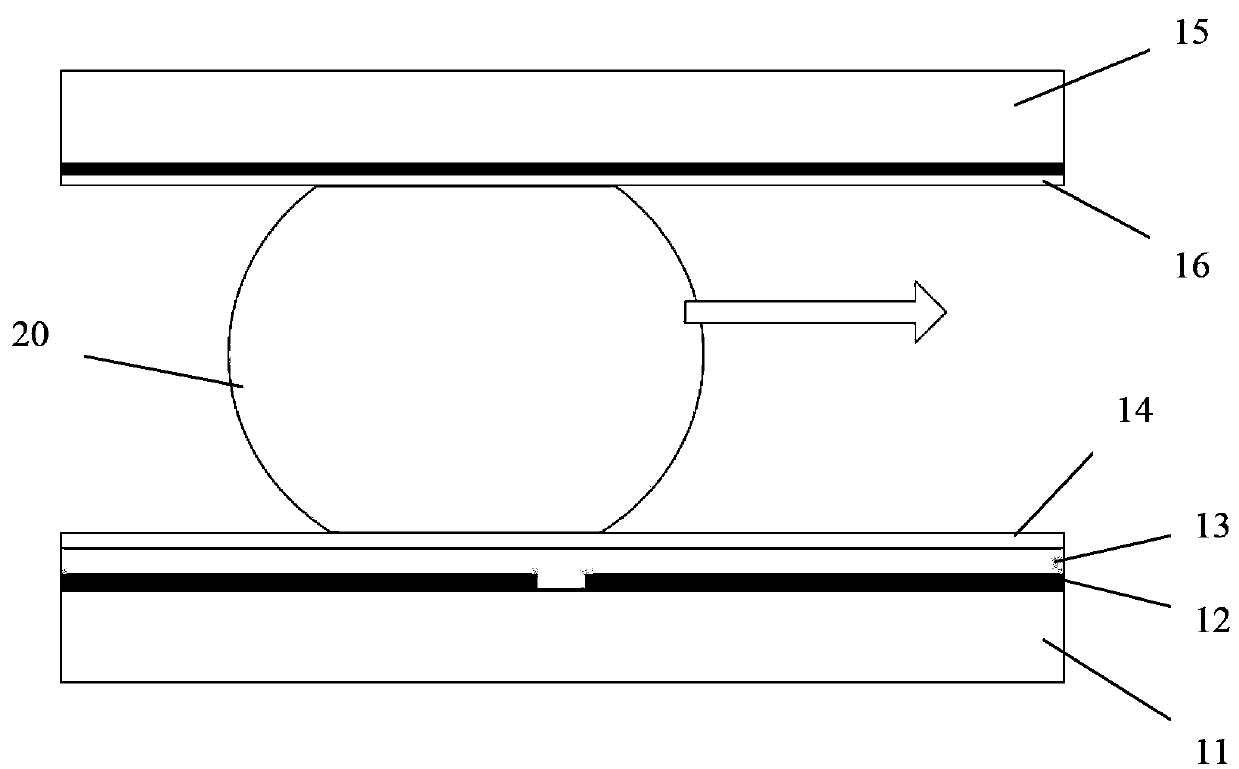

[0037] Preferably, in the above-mentioned method for transporting droplets 20 by a microfluidic chip, the microfluidic chip includes a lower pole plate and an upper pole plate oppositely arranged, and the lower pole plate includes a first substrate 11 and The driving electrode 12, the dielectric layer 13 and the first water-repellent laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com