Micro-fluidic chip clamp

A technology of microfluidic chips and fixtures, which can be used in supporting appliances, laboratory appliances, chemical instruments and methods, etc., and can solve problems such as troublesome operation, overturning, and position deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 A kind of microfluidic chip fixture

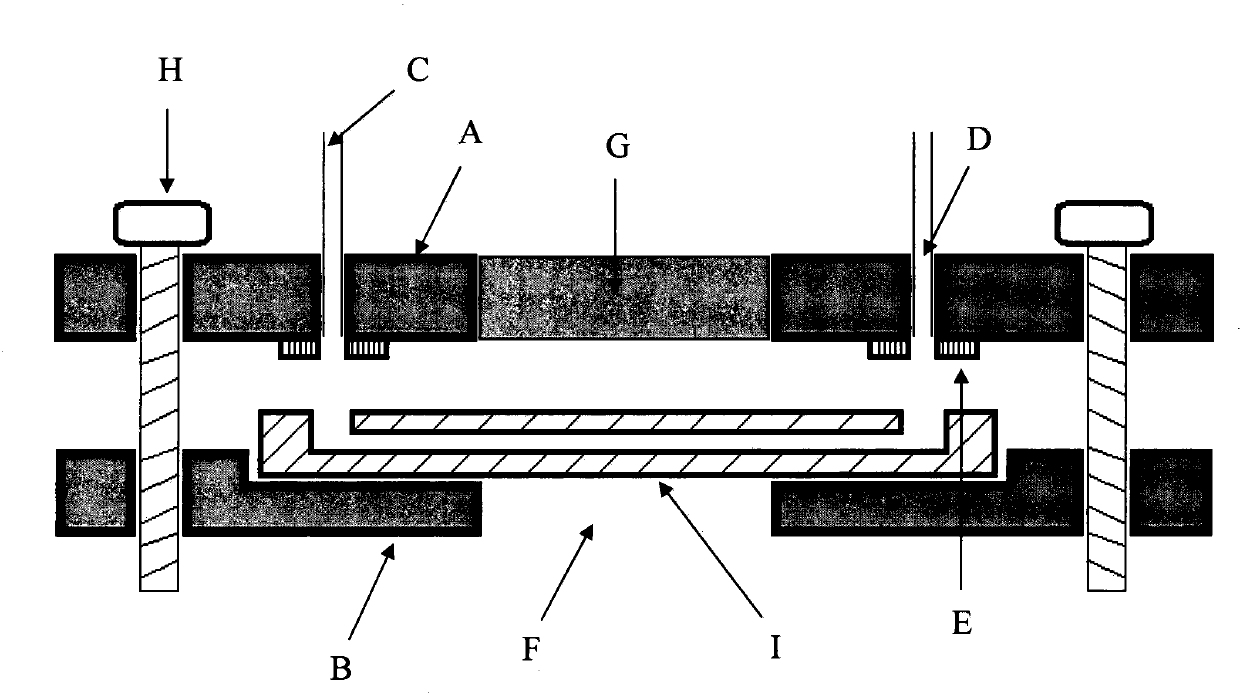

[0019] A microfluidic chip fixture, made of ABS plastic injection molding, its structure is as follows figure 1 As shown, the fixture is composed of upper and lower splints A and B, wherein the upper splint is processed with fastening threaded holes, conduit joints D, elastic gaskets E, and observation windows that can be embedded with optical devices G; the lower splint is processed with tight Solid threaded hole, chip fixing groove, hollow observation window F; when in use, place the microfluidic chip I in the two splints, align the sample pool of the chip with the elastic gasket or O-ring, and tighten it Screw H can tightly clamp the microfluidic chip between the upper and lower splints. On the one hand, it can ensure the immobilization of the microfluidic chip. On the other hand, after inserting the catheter into the catheter connector of the splint, it can be easily realized The connection between microfluidic chi...

Embodiment 2

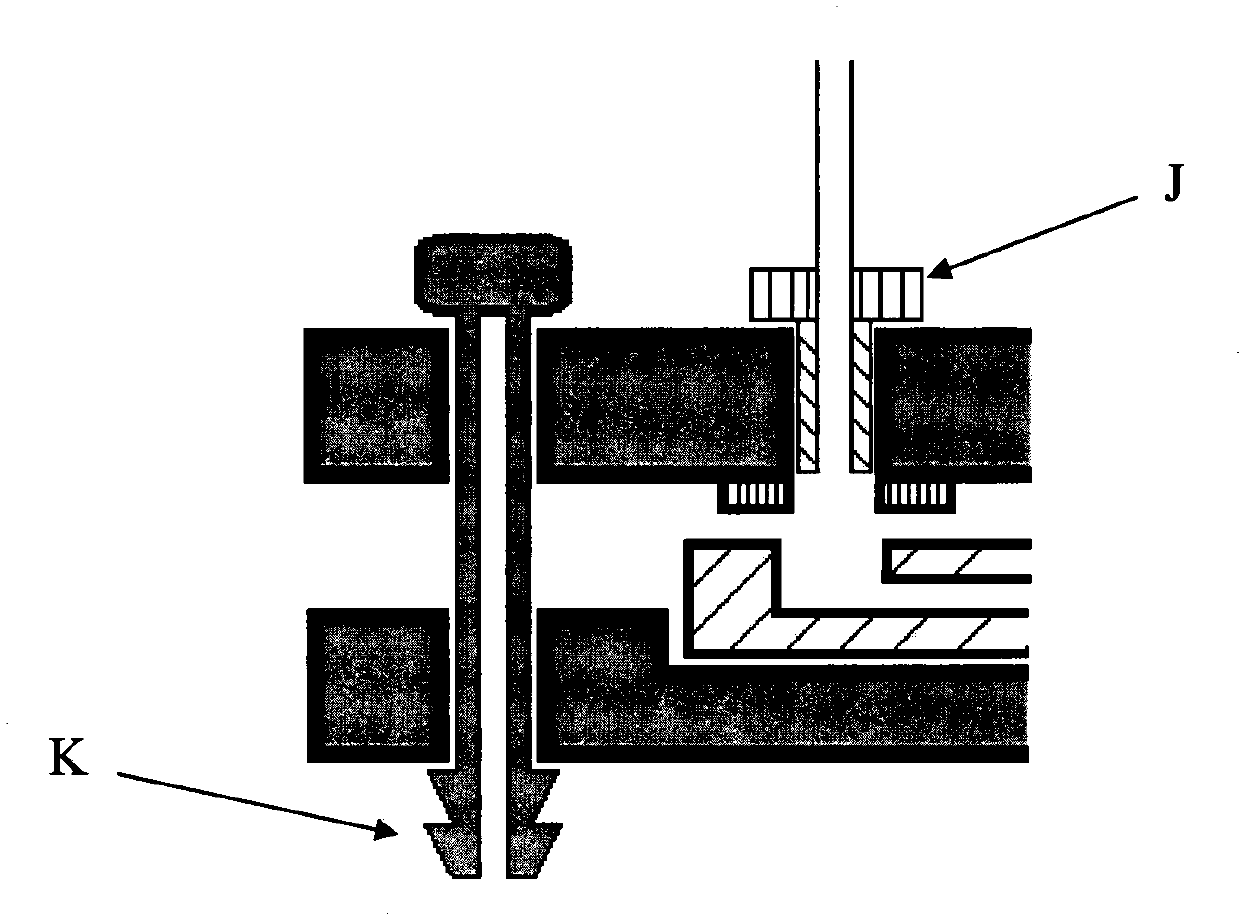

[0020] Example 2 A microfluidic chip fixture based on a hook structure

[0021] This embodiment provides a microfluidic chip fixture based on a hook structure, which is different from the fixture described in Example 1 in that the fixture provided in this embodiment uses a hook-type fastening device to fix the upper and lower splints In addition, a threaded catheter connector is used to connect the catheter to the chip.

[0022] For the hook-type structure of the splint on the microfluidic chip fixture and the structure of the threaded catheter connector, see figure 2 . When in use, the microfluidic chip I is placed in the two splints. After alignment, the microfluidic chip can be tightly clamped between the upper and lower splints only by using the hook structure. On the one hand, it can ensure that the microfluidic chip On the other hand, after screwing the threaded catheter connector with the catheter into the splint, the connection between the microfluidic chip and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com