Method and device for sorting uranium dioxide core microspheres

A technology of uranium dioxide and sorting device, which is applied in the field of sorting uranium dioxide core microspheres, and can solve problems such as clogging the feed pipe of vibrating separators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be further described below in conjunction with the drawings and embodiments. The following examples are only used to illustrate the present invention, but not to limit the scope of the present invention.

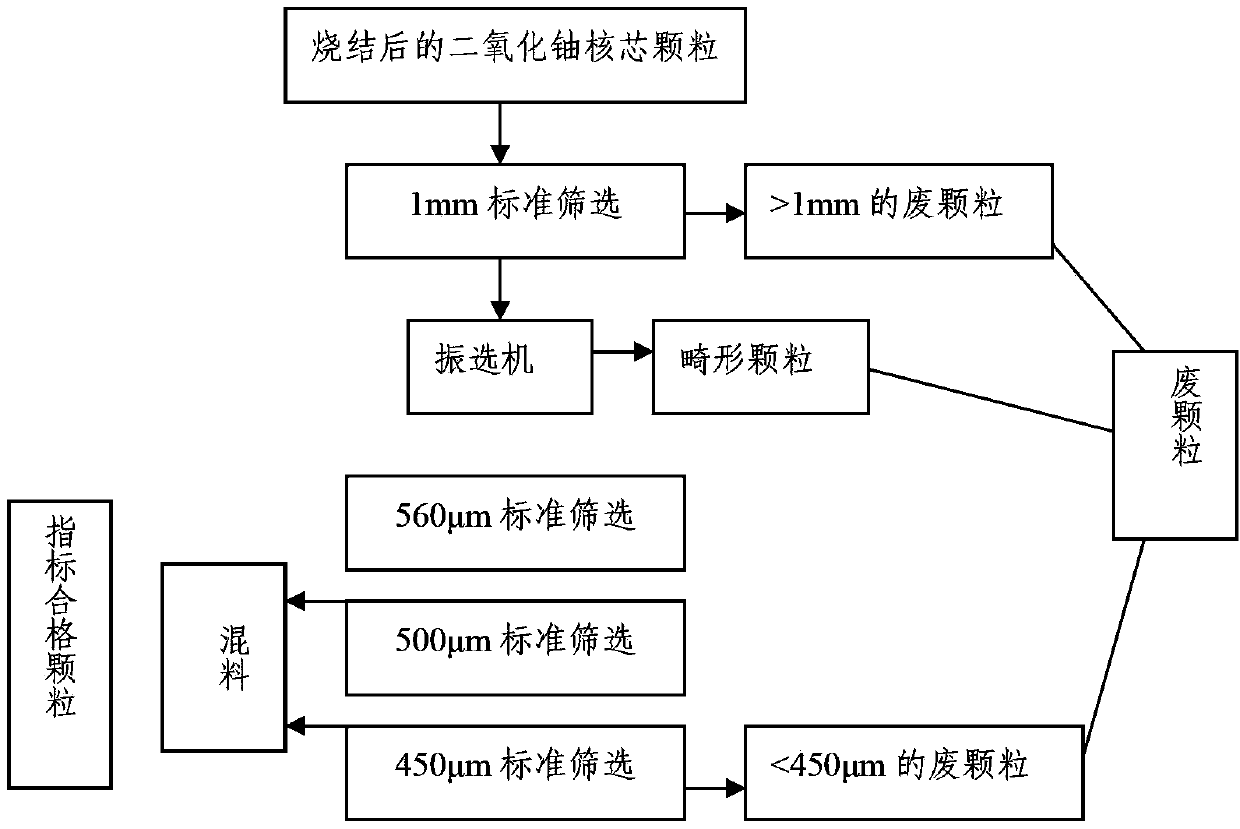

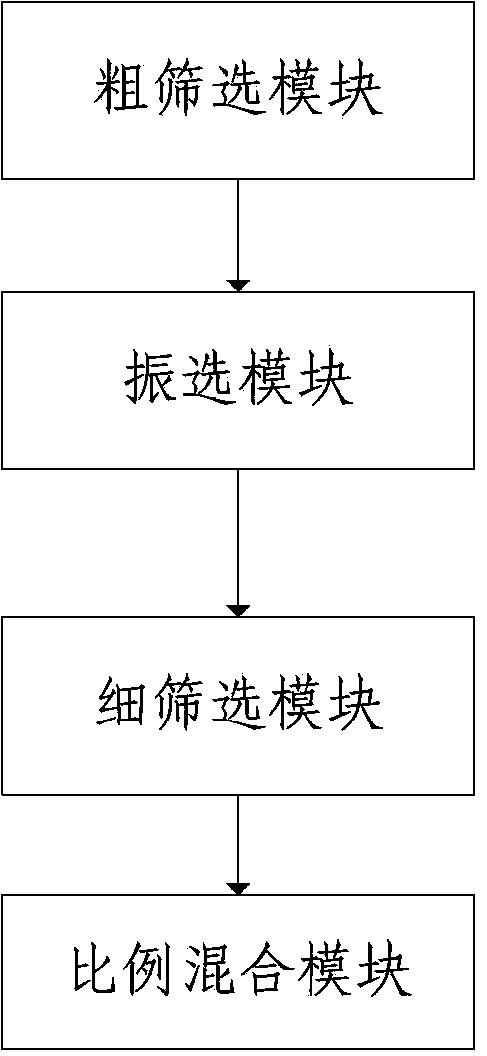

[0032] Such as figure 1 A schematic diagram of a sorting method for uranium dioxide core microspheres and as shown figure 2 A schematic diagram of a uranium dioxide core microsphere sorting device shown, the present invention adopts such as figure 1 The method shown and figure 2 Illustration of the apparatus shown for microsphere sorting of UO2 cores.

[0033] First add the uranium dioxide core microspheres sintered at high temperature into figure 2 In the coarse screening module shown, the aperture of the coarse screen is set to 1 mm, and the standard analytical sieve with a diameter of 1 mm is passed through, and the uranium dioxide core microspheres with a diameter greater than 1 mm are screene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com