Equipment and method for super-plastic molding

A superplastic molding and equipment technology, applied in the field of manufacturing, can solve problems such as difficulty in accurately knowing back pressure, wasting energy and time, and reducing yield strength, saving energy and time, increasing molding speed, and high output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

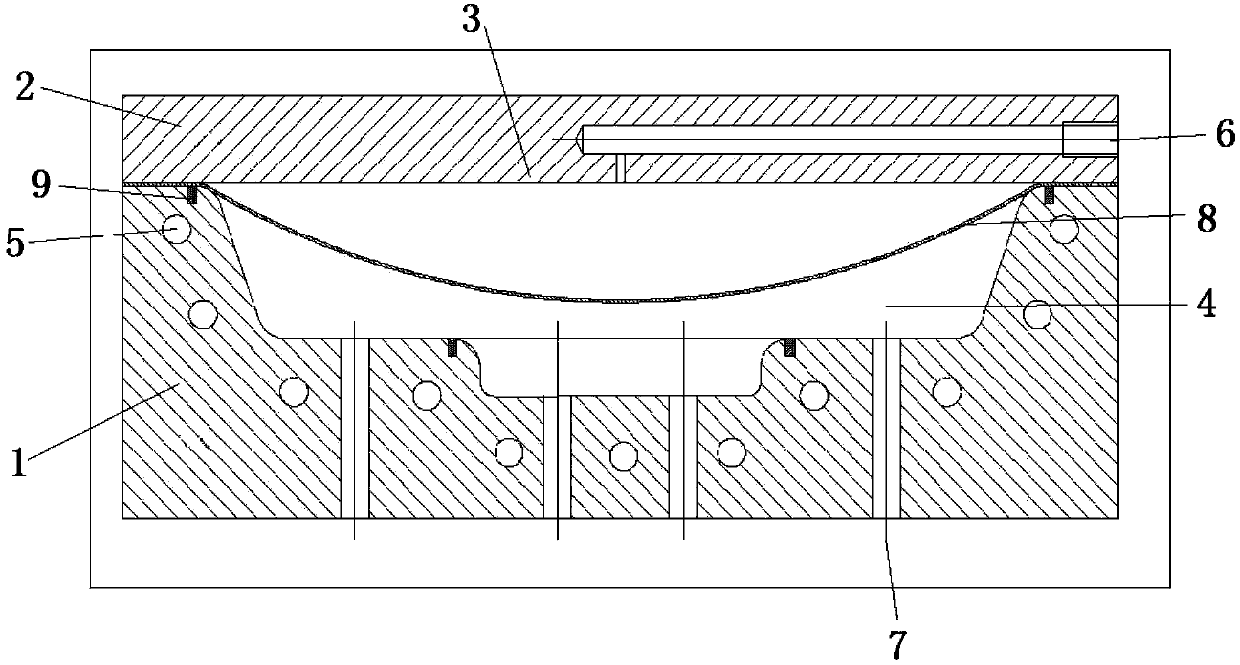

[0045] Described below, according to figure 2 Design the forming mold, use the ultrasonic detector as the detection device, use the aluminum alloy plate as the raw material, and adopt the superplastic inflation technology to prepare the forming process of the box-shaped forming part.

[0046] At the beginning, the positive pressure (upper pressure) is 1.2MPa, and the negative pressure (lower pressure) is 0.2MPa. While forming, the ultrasonic detector is used to detect the sound waves formed by the holes. When the hole formation speed increases by 10%, the back pressure will increase. 0.5MPa, when the hole formation speed drops by 9.09% (falling back to the level before the 10% rise), the back pressure is reduced by 0.5MPa to speed up the molding speed, and the whole process is repeated until the workpiece is completely molded.

[0047] Results: This process can effectively suppress holes, the holes of box-shaped formed parts are reduced by more than 50%, and the physical prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com