A combined tumor pushing knife and its application method

A combined technology of tumor pushing knife, which is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of tumor pushing knife stuck, unable to open, inconvenient, etc., so as to improve the degree of freedom and avoid The effect of interference jamming and convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

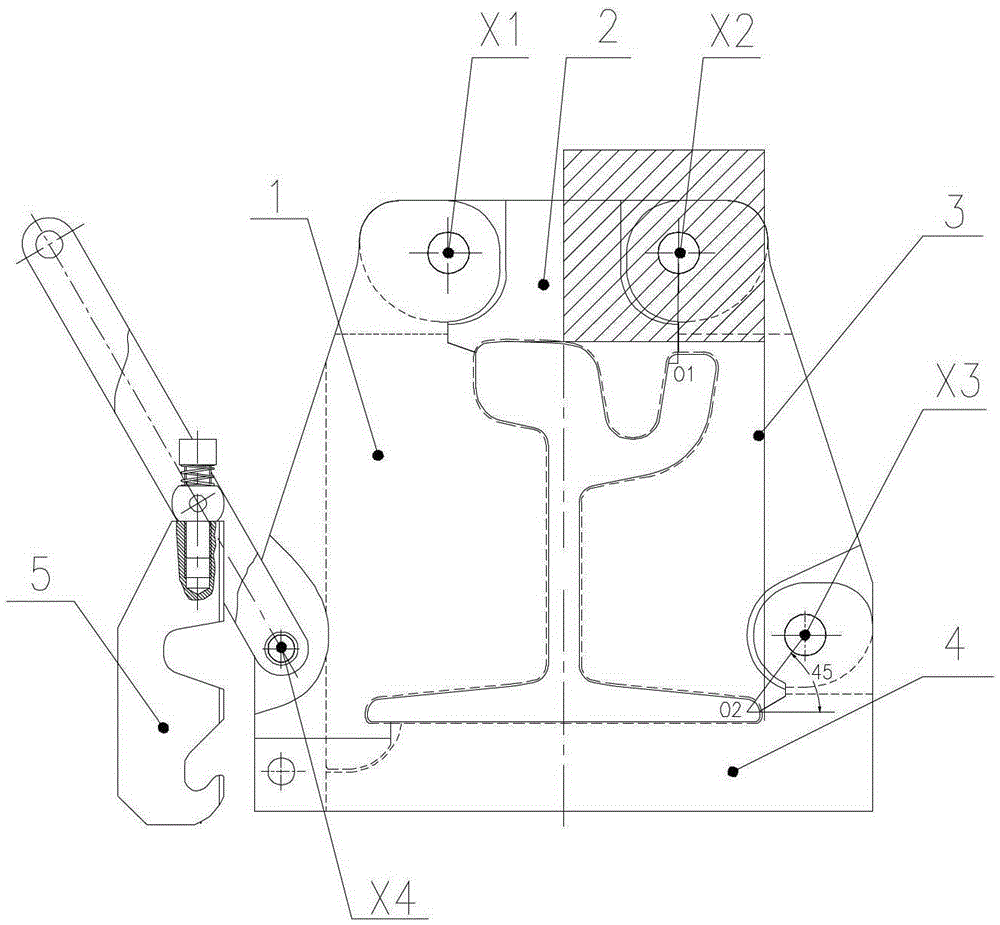

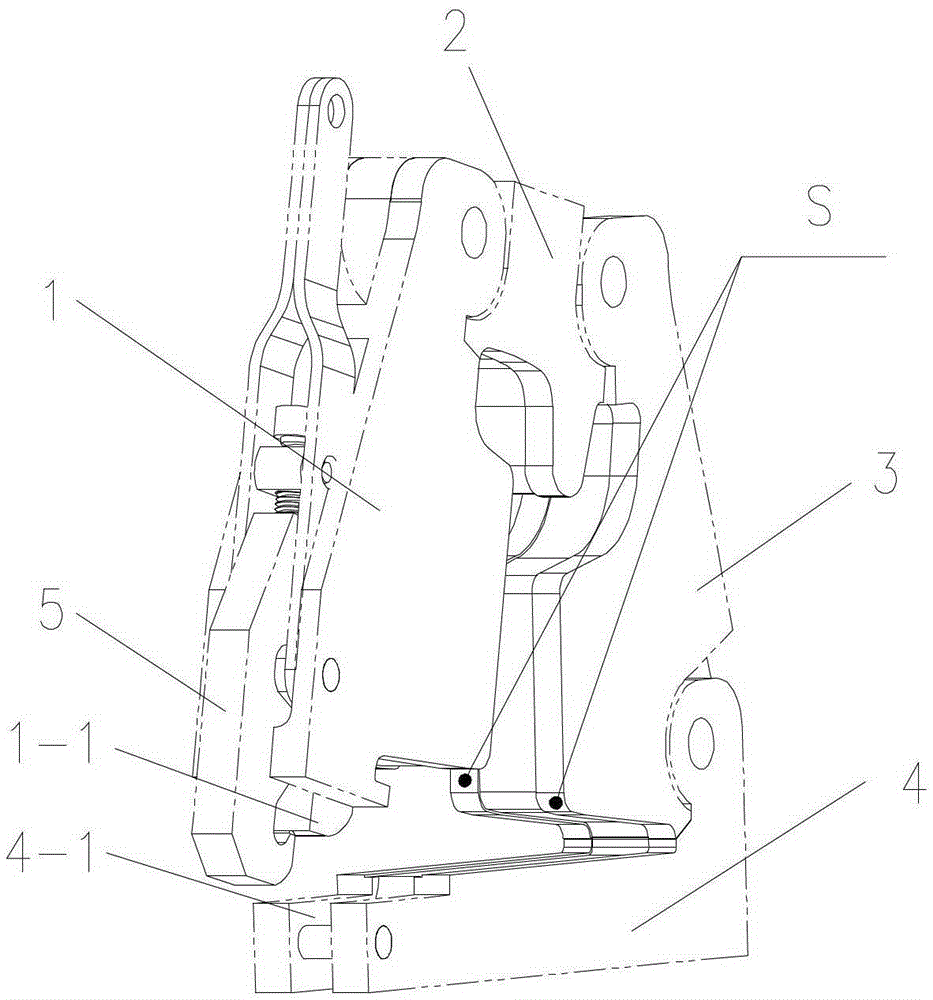

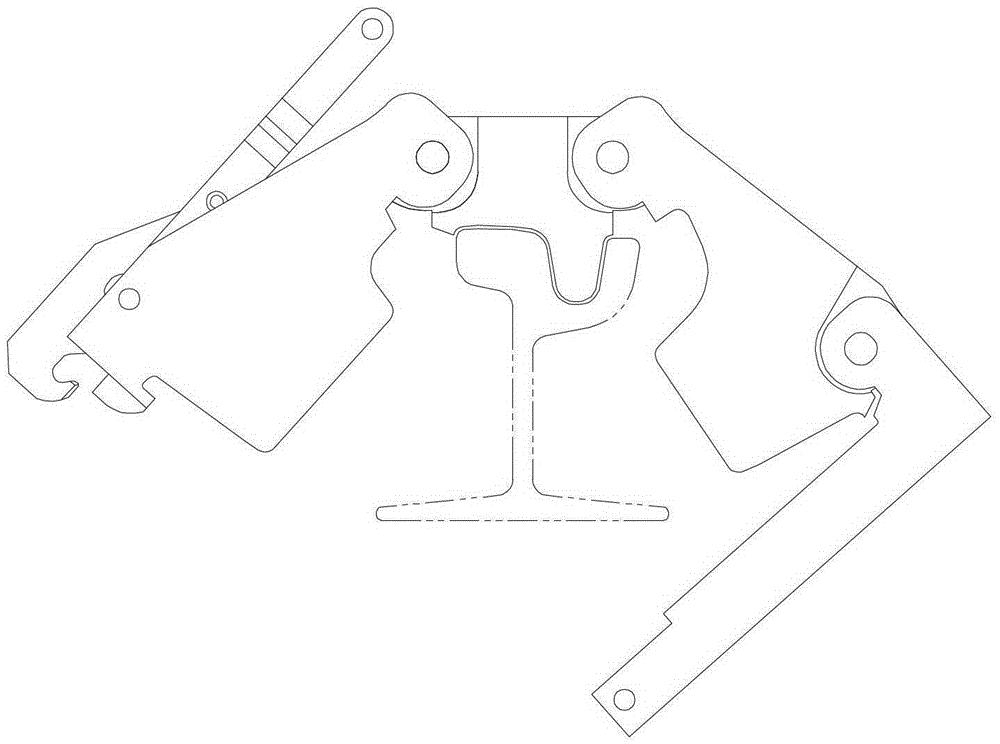

[0026] The combined tumor pushing knife of the present embodiment is as figure 1 As shown, the left cutter body 1, the upper cutter body 2, the right cutter body 3, and the lower cutter body 4 are connected in sequence. The left cutter body 1 and the upper cutter body 2 are hinged at the upper left of the envelope inner profile through the pin X1, and the locking mechanism 5 is the same as the prior art, and is hinged with the lower part of the left cutter body through the pin X4. The enveloping inner contour surrounded by the left cutter body 1, upper cutter body 2, right cutter body 3 and lower cutter body 4 basically coincides with the cross-sectional outer contour of the grooved rail. The upper cutter body 2 extends downwards to protrude into the groove of the grooved rail. The right part of the upper cutter body 2 and the upper part of the right cutter body 3 are hinged through the pin X2 at the upper right of the envelope inner profile, and the lower part of the right c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com