A kind of preparation method of lignin rubber auxiliary agent and tire rubber

A technology of rubber additives and lignin, which is applied in the field of rubber additives, can solve the problems of cumbersome preparation process and inability to enhance the wear resistance of rubber, and achieve the effects of simple preparation process, increased wear resistance, and reduced wear volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of lignin rubber auxiliary agent, comprises the following steps:

[0030] A) The alkali lignin solution is obtained after mixing the alkali lignin with the lye;

[0031] B) The above-mentioned alkali lignin solution is filtered through an alkali-resistant nanofiltration membrane to obtain a lignin rubber additive; the weight average molecular weight of the lignin rubber additive is 100-1000.

[0032] In the invention, the alkali lignin is mixed with the lye to obtain an alkali lignin solution, and then the above alkali lignin solution is filtered by a nanofiltration membrane to obtain a lignin rubber additive with a weight average molecular weight of 100-1000. The lignin rubber additive provided by the invention can increase the abrasion resistance of rubber, and the preparation process is simple.

[0033] All the raw materials of the present invention have no special limitation on their sources, they can be purchased...

Embodiment 1

[0052] Mix 50g NaOH and 2500g water to prepare an alkali solution with a mass concentration of 2%, then put 500g of untreated commercially available alkali lignin (Shandong Quanlin Chemical Co., Ltd.) into the alkali solution and stir until completely dissolved to obtain alkali lignin The solution was then circulated and filtered with a roll-type nanofiltration membrane with a molecular weight cut-off of 1000. After 2 hours, stop filtering to obtain a small molecule lignin solution, and heat it to 70°C, then slowly add sulfuric acid with a mass concentration of 30% to the above small molecule lignin solution for acid analysis until the pH value of the filtrate is 3.5. After the acid analysis is completed, the small molecule lignin mixture obtained by the above acid analysis is centrifuged to obtain solid lignin, and then the solid lignin is dried in an oven at a drying temperature of 40°C and a drying time of 8 hours to obtain Dry powdered lignin.

[0053] Wash the above-ment...

Embodiment 2

[0055] The rubber, carbon black, rubber additives and the lignin rubber additives prepared in Example 1 were mixed and vulcanized according to the following formula, and the formula was as follows:

[0056] Rubber 100g; carbon black N23445g; naphthenic oil 2.0g; stearic acid 3.0g; zinc oxide 5.0g; microcrystalline wax 1.0g; antioxidant RD2.0g; antioxidant 40201.5g; ; The lignin rubber auxiliary agent 2.0g prepared by this patent.

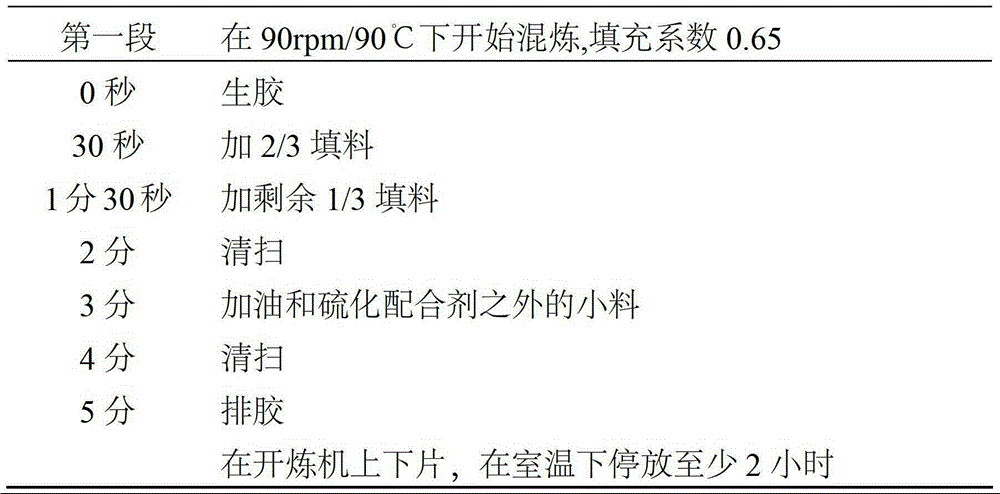

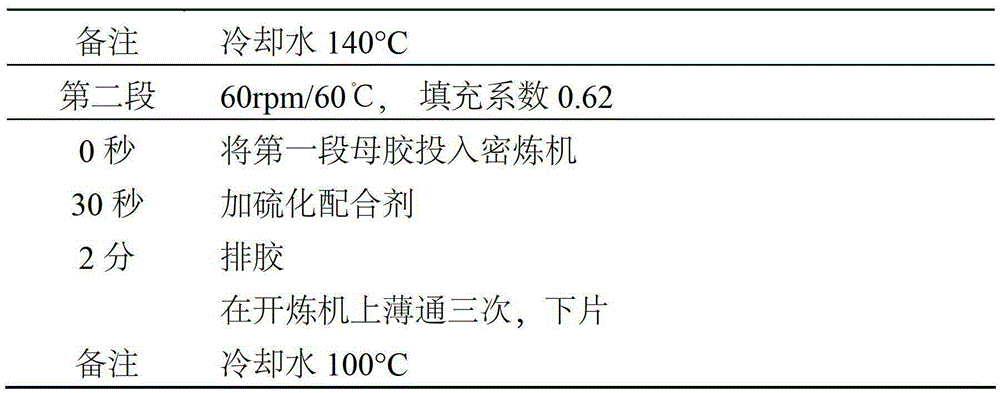

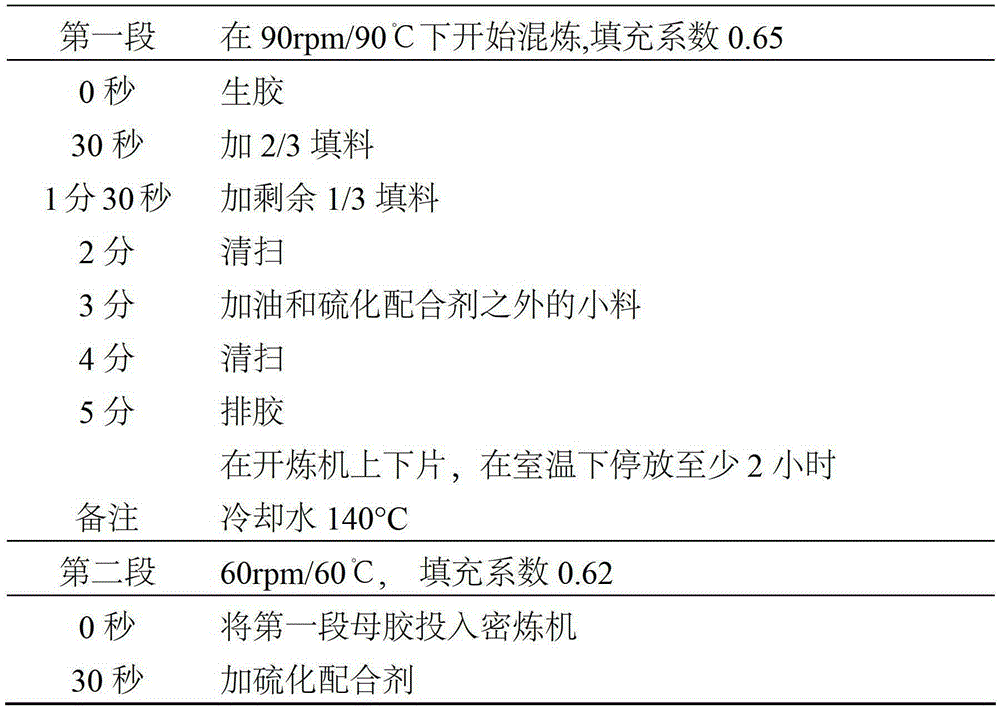

[0057] Mixing is carried out on a 1L internal mixer, and the mixing process is as follows:

[0058] Table 1 Rubber mixing process

[0059]

[0060]

[0061] Obtain the tire rubber A described in this patent after mixing through the above-mentioned process 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com