Preparation method of orange oil based unsaturated resin monomer

A resin monomer, unsaturated technology, applied in the field of preparation of unsaturated resin monomer, can solve the problems of poor toughness, poor weather resistance, high content of toxic components, etc., to improve poor toughness, improve comprehensive performance, and good product stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

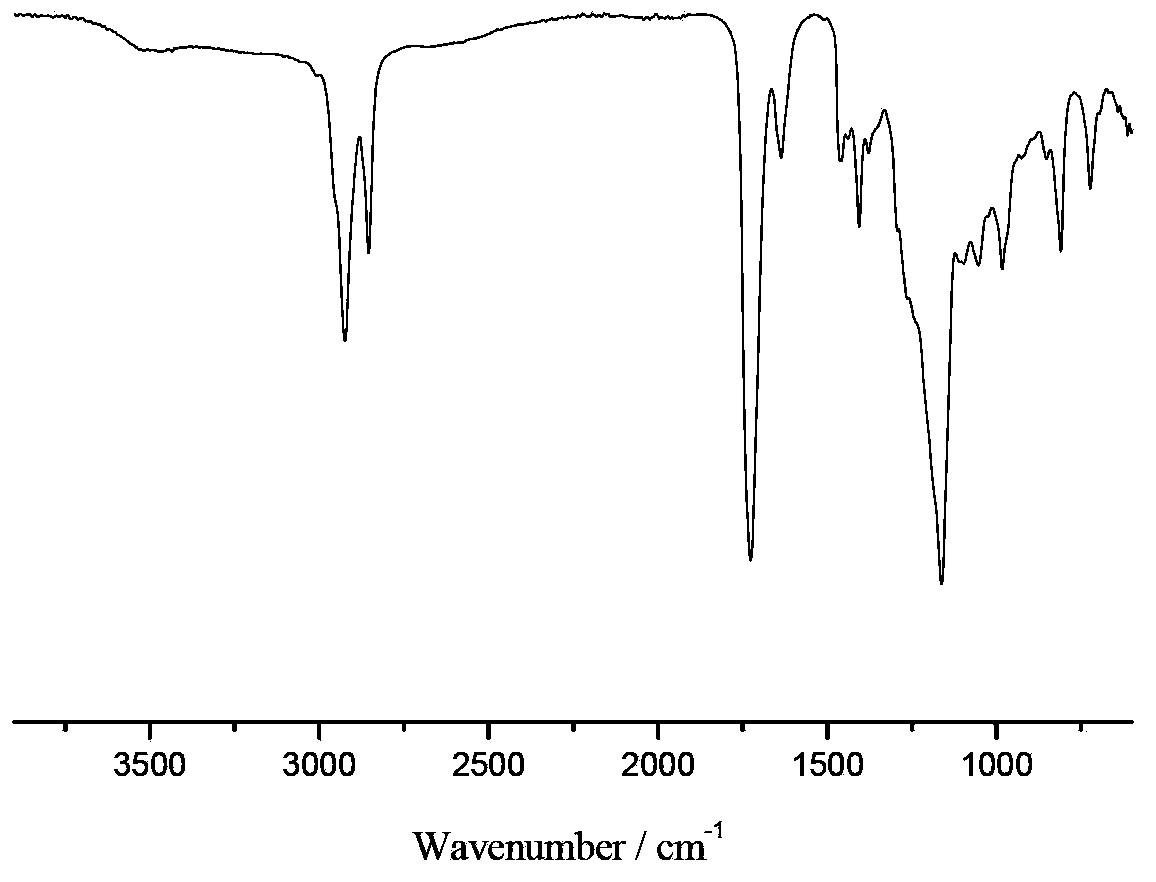

Image

Examples

Embodiment 1

[0026] Add a certain mass of maleic anhydride into the reactor, raise the temperature to 45°C to dissolve it completely, add orange essential oil dropwise in a ratio of 1:1 to the molar ratio of maleic anhydride, and add Titanium tetrachloride with a mass of 0.25% catalyst was heated to 70°C, reacted for 6 hours, and unreacted orange essential oil, maleic anhydride and a small amount of by-products were removed by vacuum distillation to obtain an intermediate product orange oil-based maleic anhydride. Dissolve the obtained orange oil-based maleic anhydride in water, and then add dropwise an aqueous solution of sodium hydroxide (the amount of sodium hydroxide is equal to the number of moles of carboxyl groups), and continue the reaction for 3 hours after the dropwise addition. After the reaction was completed, the solvent water was distilled off and vacuum-dried to obtain the sodium salt of orange oil maleic anhydride. The sodium salt of orange oil base maleic anhydride and chl...

Embodiment 2

[0028] Add a certain amount of fumaric anhydride into the reactor, raise the temperature to 60°C to dissolve it completely, add orange essential oil dropwise at a ratio of 1.2:1 to the molar ratio of fumaric anhydride, and add Titanium tetrachloride with a mass of 0.25% catalyst was heated to 150°C, reacted for 4 hours, and unreacted orange essential oil, fumaric anhydride and a small amount of by-products were removed by vacuum distillation to obtain an intermediate product orange oil-based fumaric anhydride. Dissolve the obtained orange oil-based fumaric anhydride in water, and then add dropwise an aqueous solution of sodium hydroxide (the amount of sodium hydroxide is equal to the number of moles of carboxyl groups), and continue the reaction for 1 hour after the dropwise addition. After the reaction was completed, the solvent water was distilled off, and vacuum-dried to obtain the sodium salt of orange oil fumaric anhydride. The sodium salt of orange oil-based fumaric anhy...

Embodiment 3

[0030] Add a certain mass of crotonic acid into the reactor, raise the temperature to 55°C to dissolve it completely, add orange essential oil dropwise in a ratio of 1.1:1 to the molar ratio of crotonic acid, and add 0.5% of the total mass of the reactants Catalyst butadiene amine, heat up to 90°C, react for 5 hours, and distill off unreacted orange essential oil, crotonic acid and a small amount of by-products under reduced pressure to obtain the intermediate product orange oleyl crotonic acid. Dissolve the obtained orange oleyl crotonic acid in water, and then add dropwise an aqueous solution of sodium hydroxide (the amount of sodium hydroxide is equal to the number of moles of carboxyl groups), and continue the reaction for 2 hours after the dropwise addition. After the reaction was completed, the solvent ethanol was distilled off, and vacuum-dried to obtain the sodium salt of orange oil crotonic acid. The sodium salt of orange oleyl crotonate and chloropropene are dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com