Device and method for simultaneously controlling flame shape and flame temperature

A technology of flame shape and flame temperature, which is applied in the field of simulated fire source control, can solve the problems of small fire source flame, inability to realize program control, and does not consider the influence of flame, etc., to achieve the effect of uniform airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

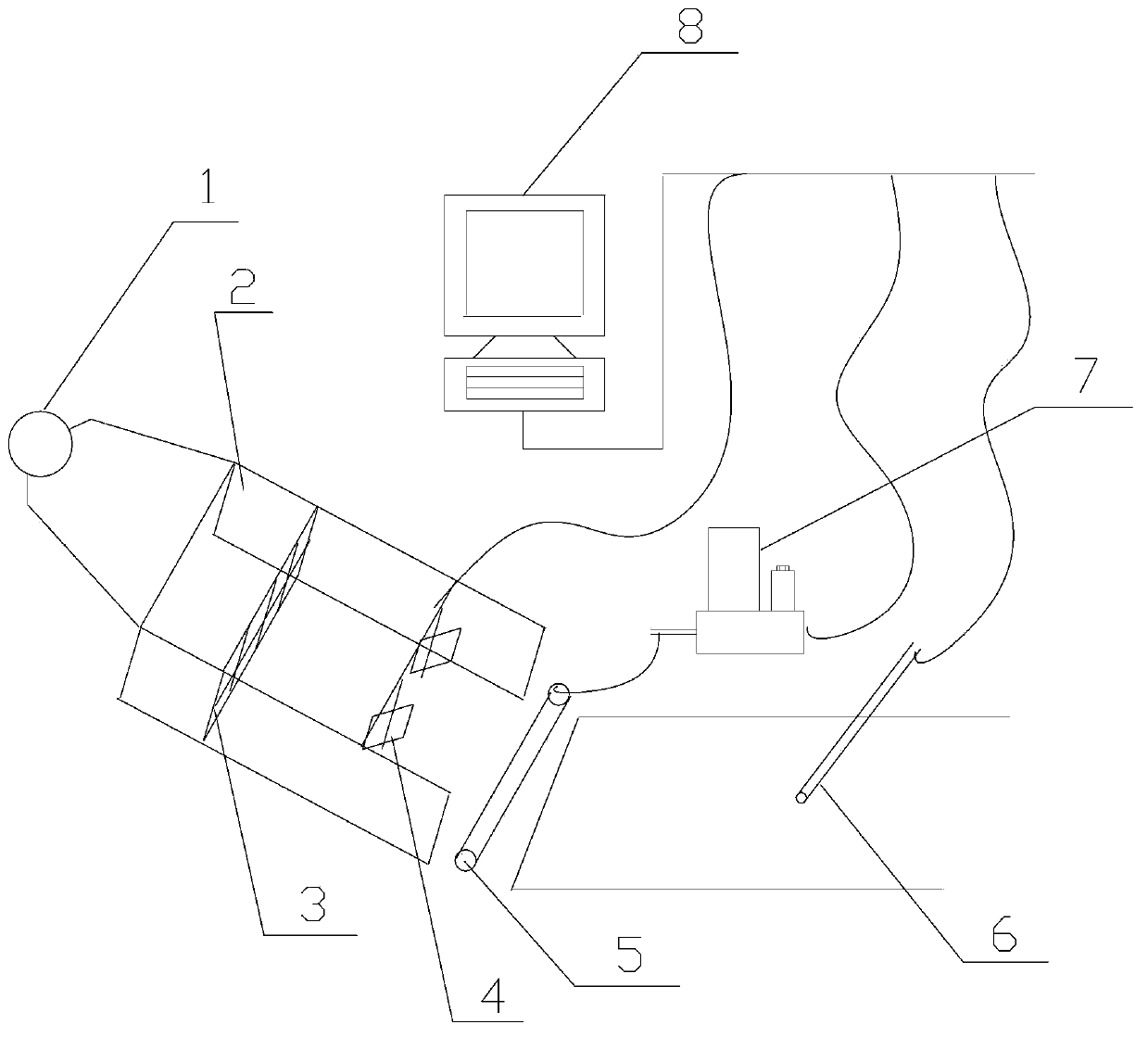

[0034] like figure 1 As shown, a device for simultaneously controlling flame shape and flame temperature in this embodiment includes an air blower 1, an air duct 2, a steady flow grid 3, a guide vane 4, a burner 5, a thermocouple 6, and a gas mass flowmeter. 7, computer 8, test bench, etc. Each of the above devices is arranged in a combustion chamber, the combustion chamber is made of heat insulating material, and cameras are provided at several positions of the combustion chamber for observing the shape of the flame. The combustion plate to be tested is fixed on the test bench, the burner 5 is arranged between the air outlet of the air duct 2 and the test bench, and the air blower 1 supplies air through the air duct 2 .

[0035]In order to fully consider the influence of the external wind speed on the fire source flame, the fan 1 used in this embodiment is either a centrifugal fan or an axial flow fan, and the wind speed ranges from 0 to 10 m / s. Described combustion plate i...

Embodiment 2

[0048] The structure of this embodiment is the same as that of Embodiment 1 except for the following features:

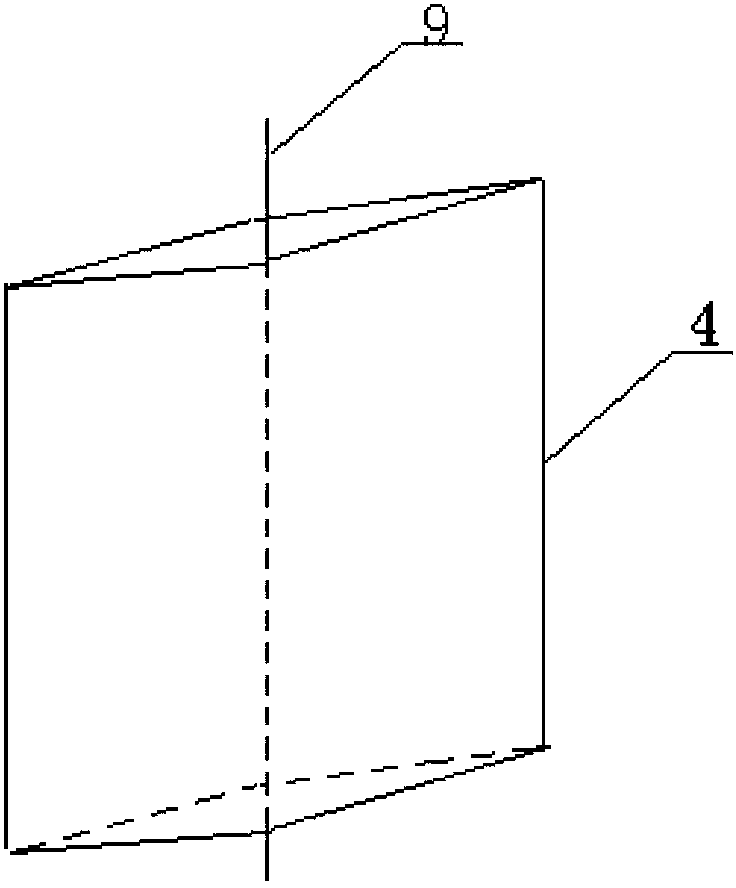

[0049] In this example, the number of guide vanes 4 is 8, and the grid size is 80mm×80mm.

Embodiment 3

[0051] The structure of this embodiment is the same as that of Embodiment 1 except for the following features:

[0052] In this example, the number of guide vanes 4 is 10, and the grid size is 30mm×30mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com