Apparatus for backside EMMI failure analysis and failure analysis method thereof

A failure analysis, backside technology, used in electronic circuit testing, optical testing flaws/defects, non-contact circuit testing, etc., can solve problems such as poor repeatability, difficulty, and difficult operation, and achieve high repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

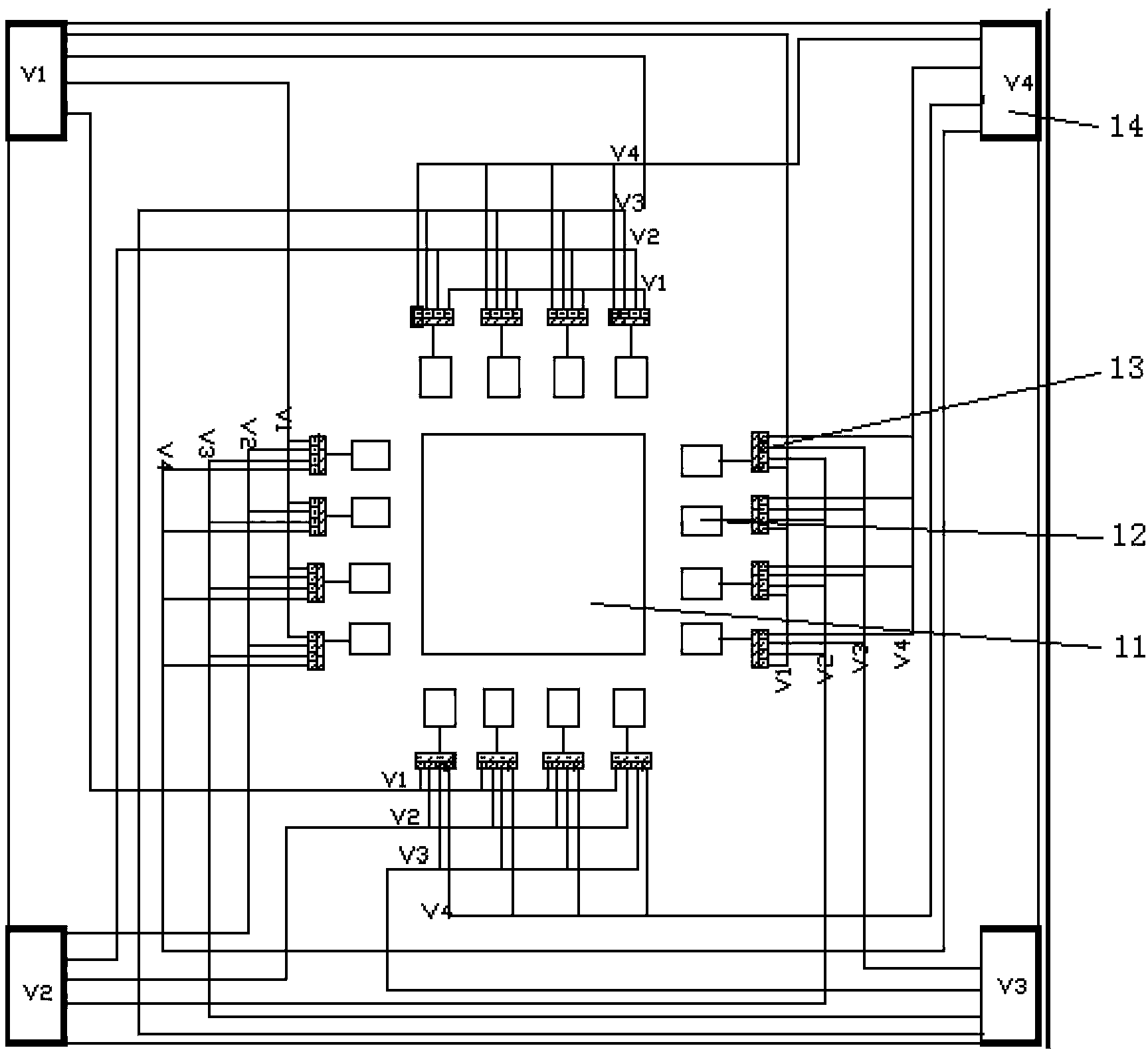

[0038] The device for EMMI failure analysis on the back side of the present invention includes a PVC (Polyvinyl chloride resin polyvinyl chloride) circuit board and a signal input and output base for fixing; the signal input and output base can conduct signals;

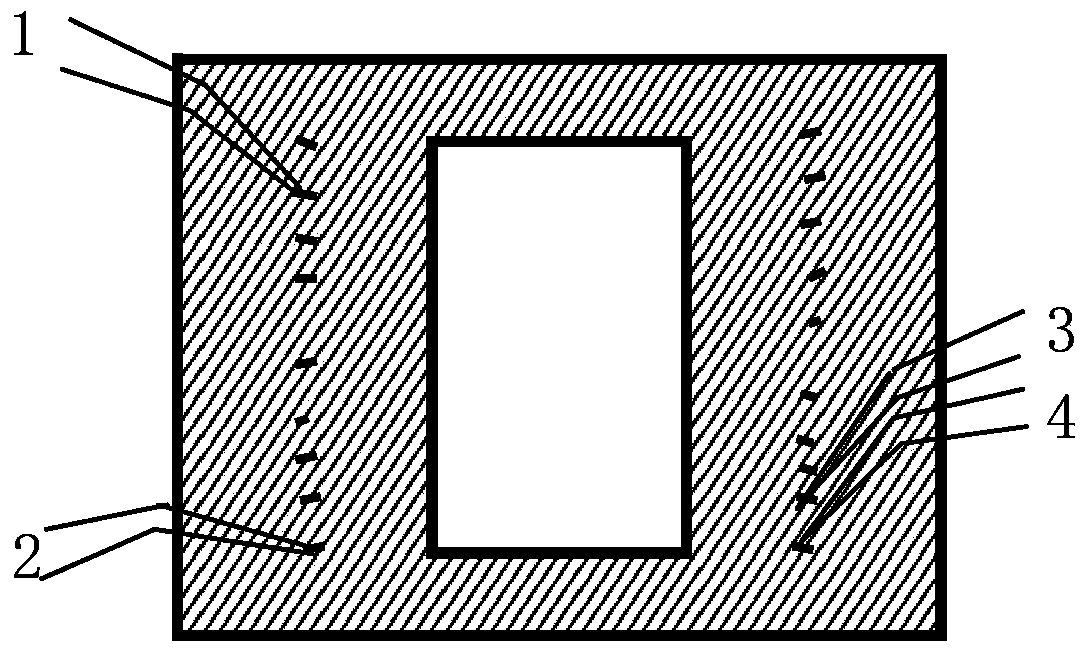

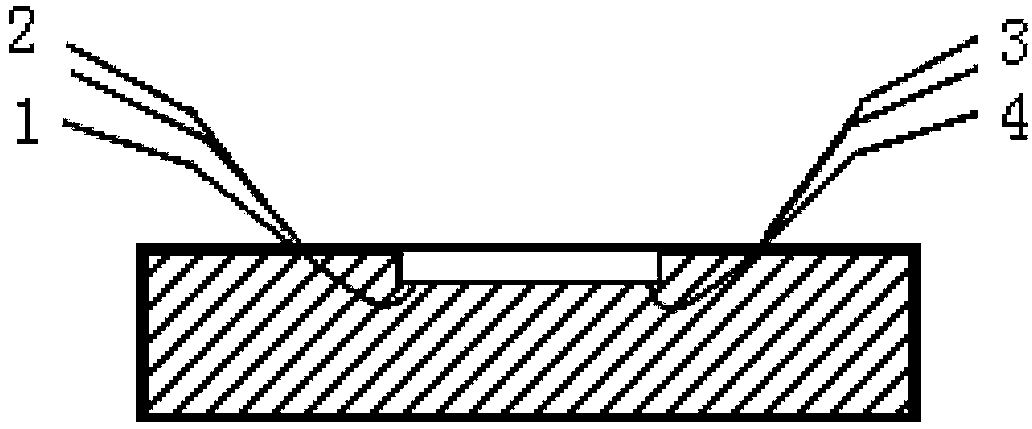

[0039] Such as image 3 As shown, the center of the PVC circuit board is provided with a transparent plexiglass sheet 11; the plexiglass sheet 11 is used to position the bare chip, and will not block the EMMI to capture the infrared spectrum;

[0040] On the front side of the PVC circuit board, a plurality of metal pins 12 are arranged around the plexiglass sheet 11; four on each side have a total of sixteen metal pins 12; each metal pin 12 can be connected to at least six bare chip pins ;

[0041] The four corners of the PVC circuit board are respectively provided with circuit board metal pads (pads) 14;

[0042] Each metal pin 12 is connected to a jumper interface 13 by metal wire respectively, and each jumper int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com