An environment-friendly printing processing system

A treatment system and recycling treatment technology, applied in the direction of filtration separation, filtration circuit, chemical instruments and methods, etc., can solve environmental hazards and other problems, and achieve the effect of reducing emissions and reducing pollution impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

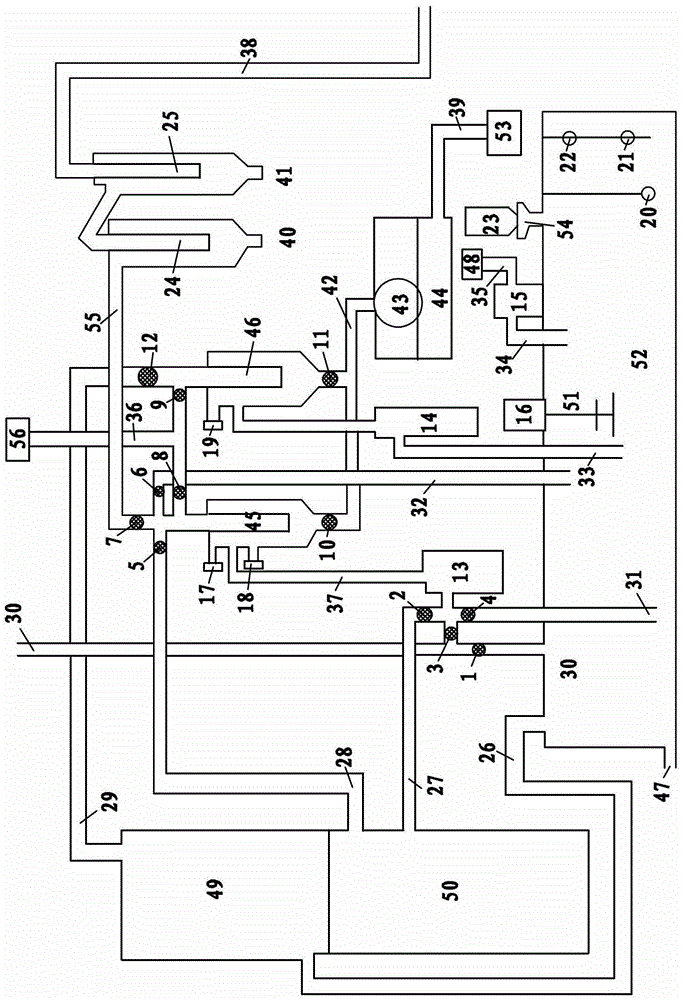

[0020] Such as figure 1 As shown, this embodiment discloses an environmentally friendly printing processing system, including a developing water washing part 49, a developing chemical washing part 50, a comprehensive treatment box 52, a first filter 45, a second filter 46, a third filter 24, The fourth filter 25, the developer solution circulation treatment neutralization pump 13, the water washing circulation treatment pump 14, the air pump 56; the developing medicine washing part 50 is connected to the first filter 45 and the comprehensive treatment box 52 respectively, and the first filter 45 passes through the developing In the liquid circulation process, the pump 12 is connected to the comprehensive treatment tank 52, on the pipeline where the developing chemical washing part 50 is connected to the first filter 45, on the pipelines where the developing chemical washing part 50 is respectively connected to the comprehensive processing tank 52, and in the developing solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com