Infrared lamp tube heated baking oven and coater

A technology of infrared lamps and ovens, applied in the field of coating machines, which can solve the problems of uneven wind in the middle and on both sides, easy cracking of coverings, long drying time, etc., achieve short heating time, reduce the number of oven sections, and reduce heating time long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

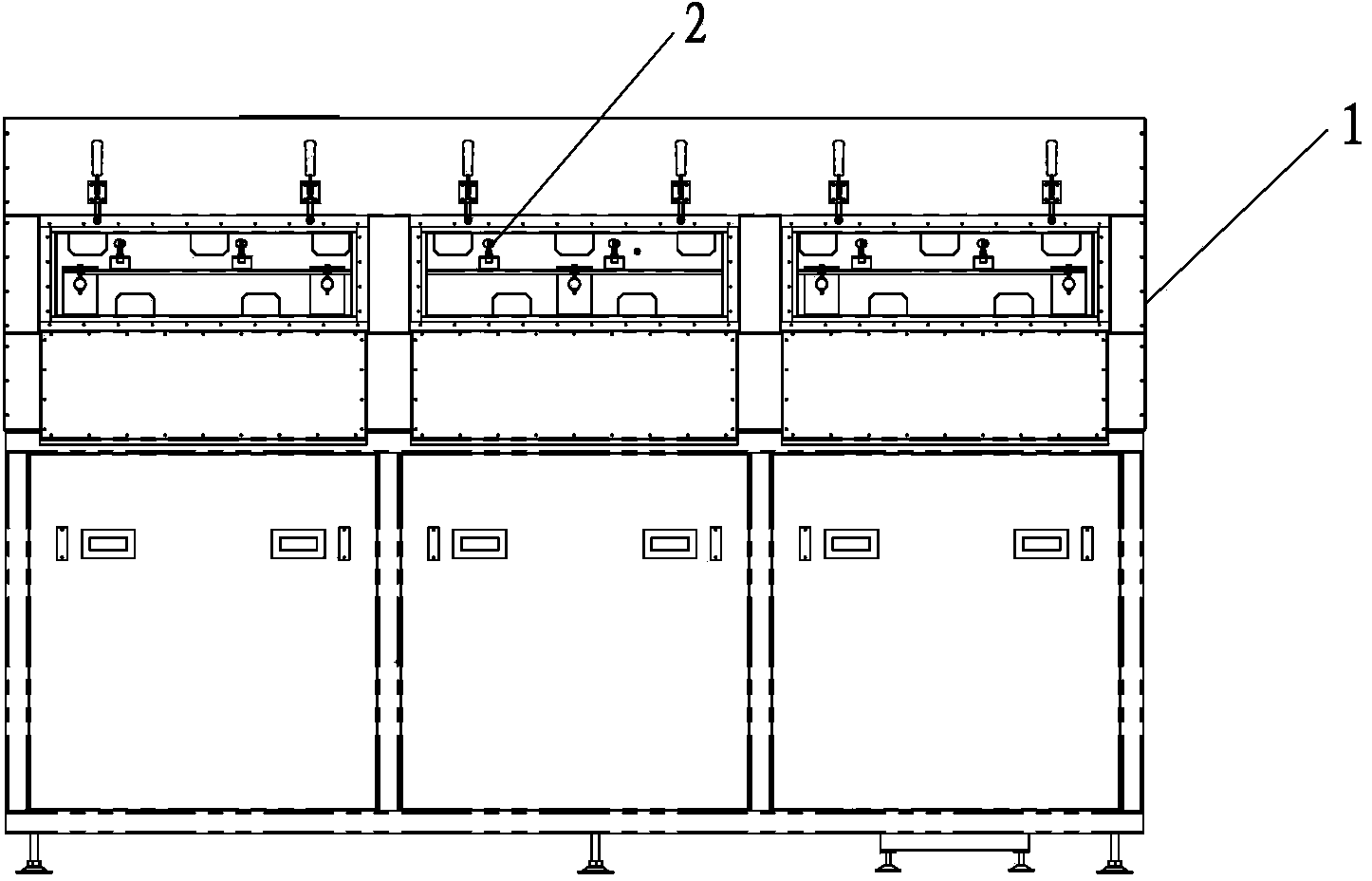

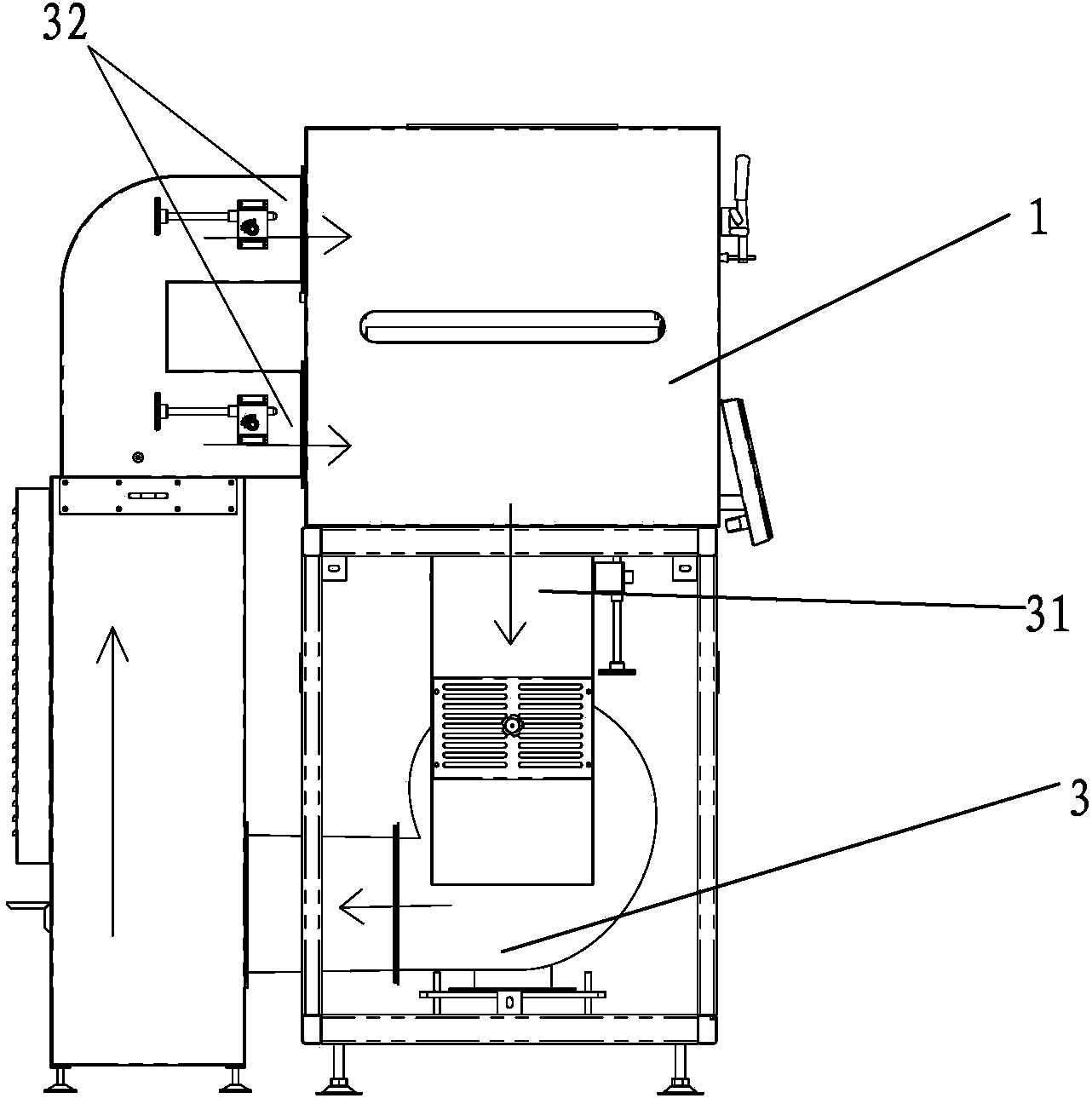

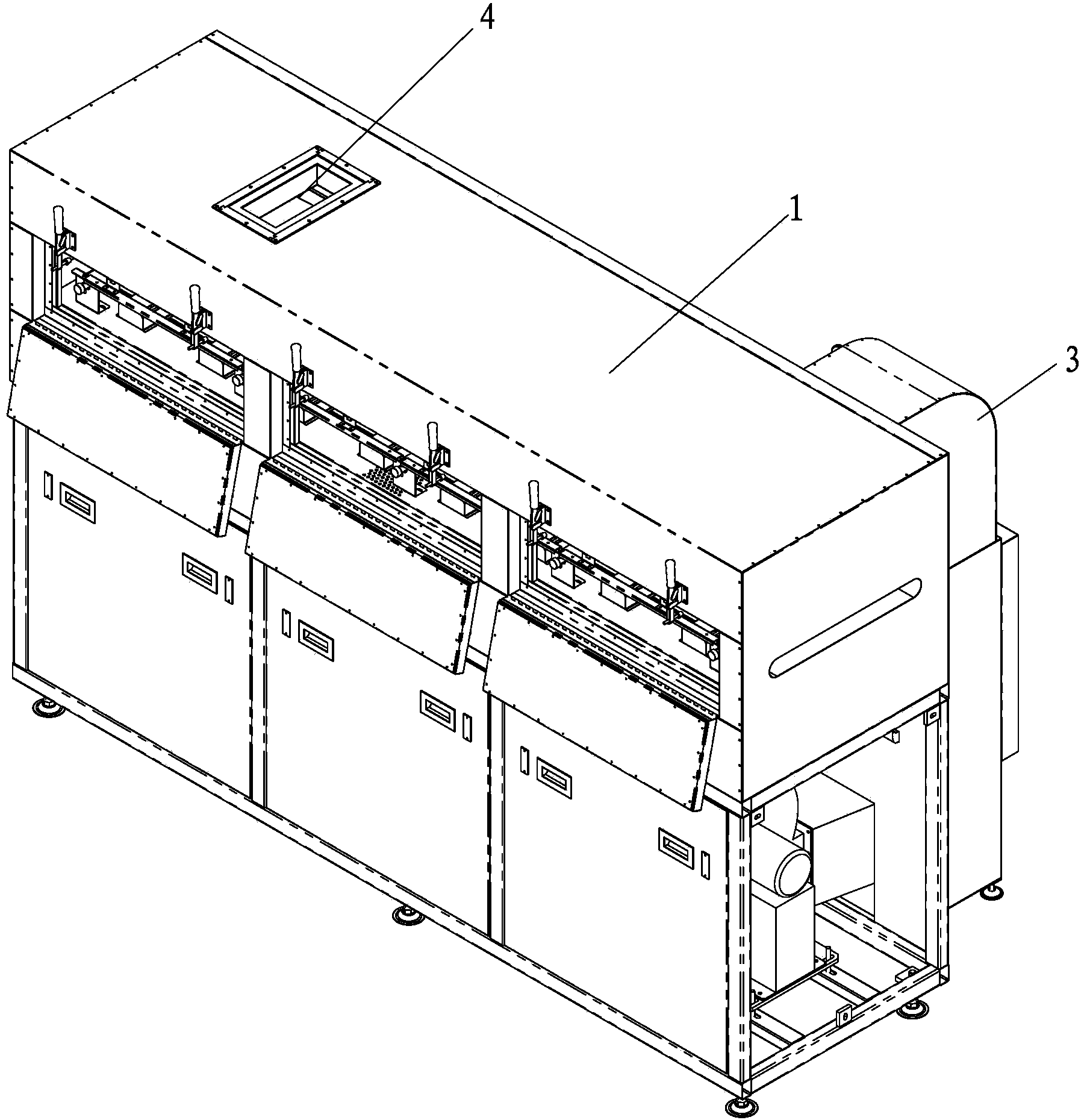

[0021] see Figure 1 to Figure 3 In this embodiment, an oven heated by infrared lamp tubes includes an oven main body 1, a return air system 3 and a heating system; the heating system includes a plurality of infrared lamp tubes 2, which are arranged on the oven main body The inner wall of 1, the infrared lamp 2 is point-to-point radiation, the same oven body 1 can save energy by 60%, and the preheating time is fast, the heating time is short, and the predetermined temperature can be reached in a short time, the drying efficiency is high, and the oven can be faster The operation of the oven may reduce the number of oven sections, improve efficiency, and save costs; the return air system 3 includes an air duct, and the two ends of the air du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com