Expanding mill component installing device and method

A technology for installing equipment and diameter expanding machines, applied in the field of diameter expanding machines, can solve the problems of easy driving, slow mold changing speed, and cantilever state, etc., to improve the installation efficiency, ensure the installation accuracy, and avoid the effects of manual labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

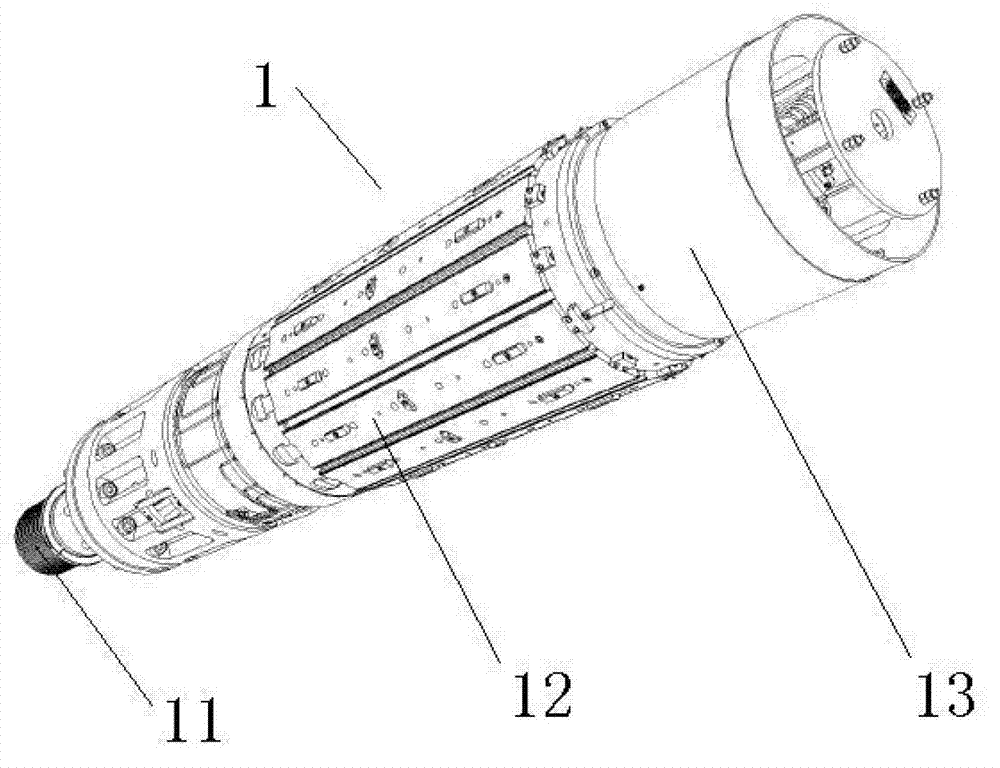

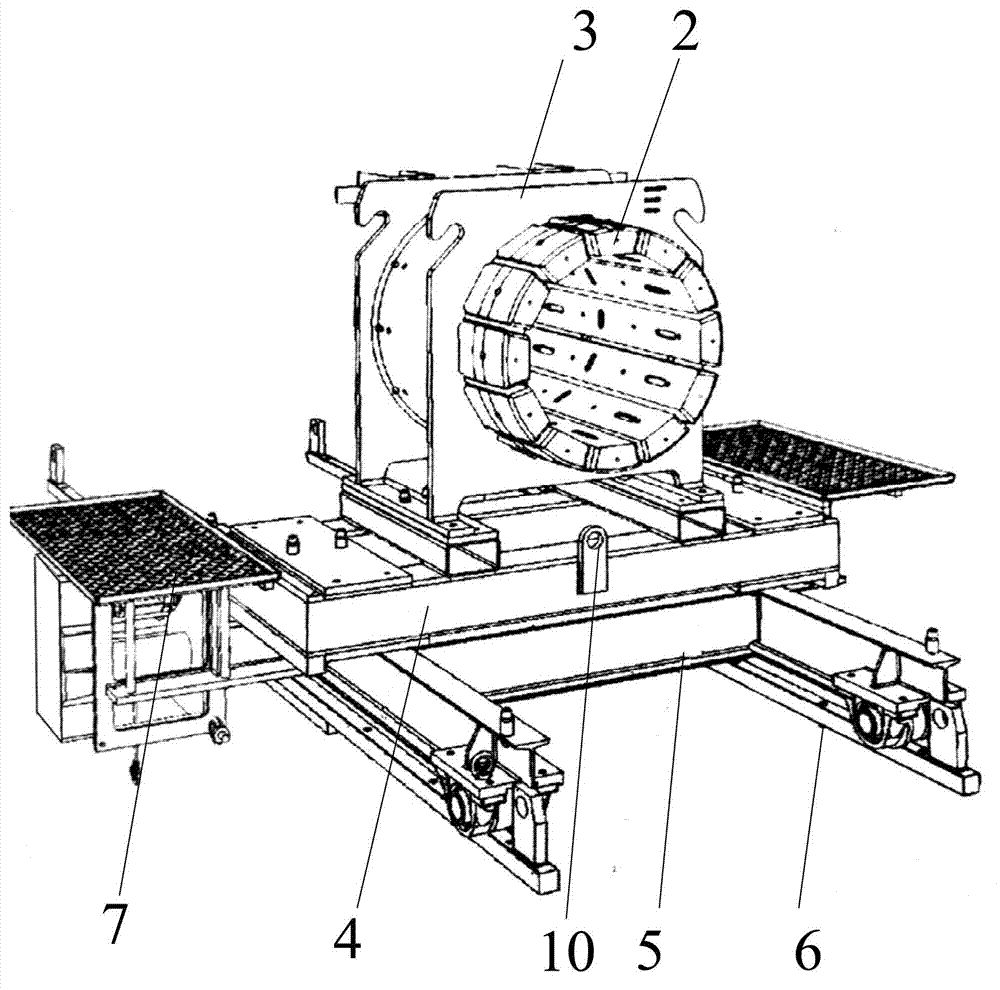

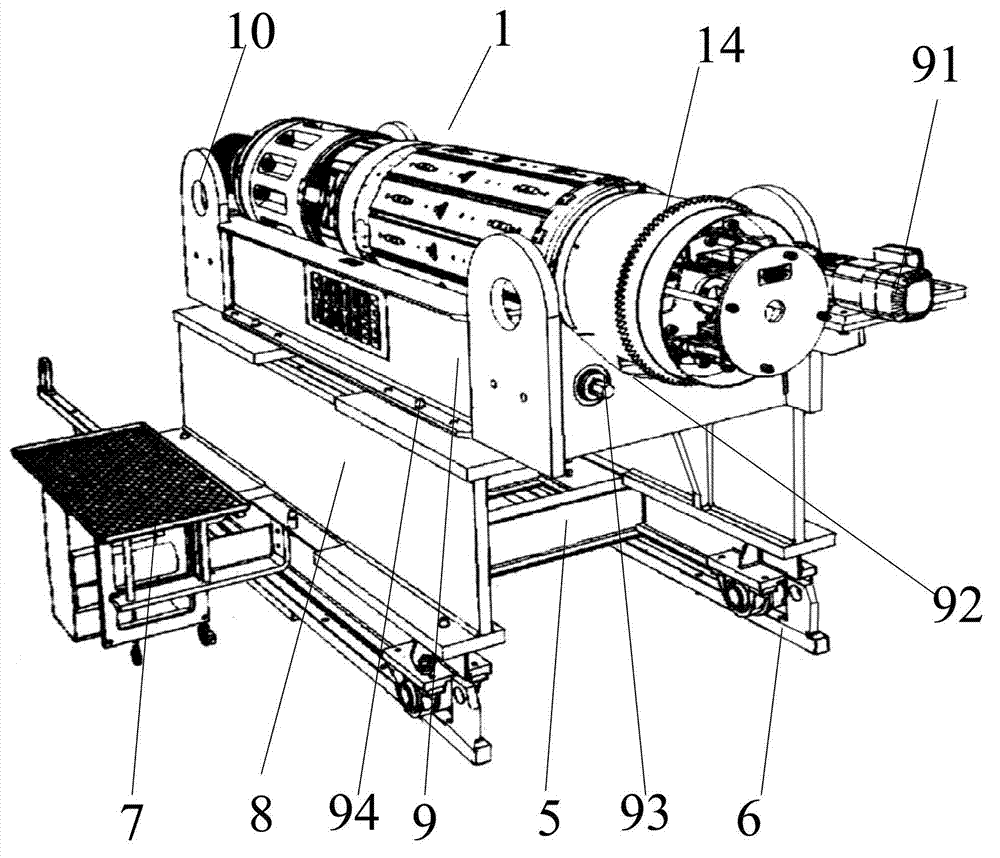

[0035] see Figure 2-Figure 4 , the present invention provides a kind of installation equipment that is used for expanding machine parts, comprises transport vehicle 5 and the frock that is installed on the transport vehicle 5, and tool is used for assisting in installing diameter expanding machine parts, and transport vehicle 5 comprises wheel 51 and is arranged on wheel 51 and the vehicle frame 52 that is connected with its wheel 51, the upper end face of vehicle frame 52 is provided with the first positioning pin 53 that is used for fixing frock, and the bottom of frock is provided with first positioning hole, and the first positioning hole and the first positioning pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com