Large PP transfusion bottle blank die based on three-flap type glue feeding

A large infusion and glue-feeding technology, which is applied in household appliances, other household appliances, applications, etc., can solve the problems of accelerated wear of the nozzle tip, reduced service life of the nozzle tip, and decreased matching accuracy, achieving good orientation, Increase the service life and cooperate with the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

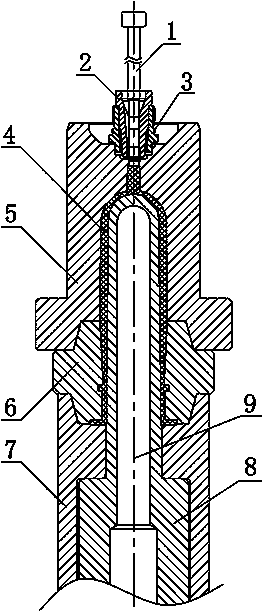

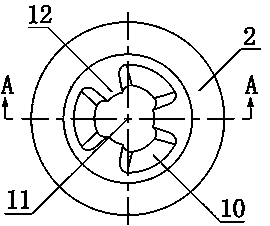

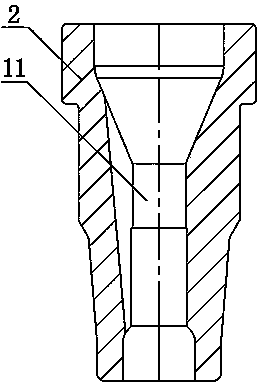

[0018] Such as figure 1 , figure 2 and image 3 As shown, a preform mold for PP large infusion bottle based on three-lobed glue feeding, which includes tip 2, nozzle sleeve 3, injection cavity 5, die lip 6, core injection sleeve 7, core injection 8 and valve needle 1 , the nozzle tip 2 is set inside the nozzle sleeve 3, the lower part of the nozzle sleeve 3 is matched with the top of the injection cavity 5, the lower part of the injection cavity 5 is connected with the upper part of the die lip 6, and the lower part of the die lip 6 is matched with the top of the injection core sleeve 7 connection, the injection core 8 is installed inside the injection core sleeve 8, and the front end of the injection core 8 passes through the die lip 6 and extends into the interior of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com