Seal strip online velvet plastering method and apparatus thereof

A technology of sealing strip and velvet, applied in the field of velvet on the surface of rubber products, can solve the problems of affecting product quality and performance, affecting product quality and performance, low bonding strength, etc., so as to improve poor bonding, improve performance and service life , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In this embodiment, the sealing strip of the automobile instrument panel is selected to be pasted online.

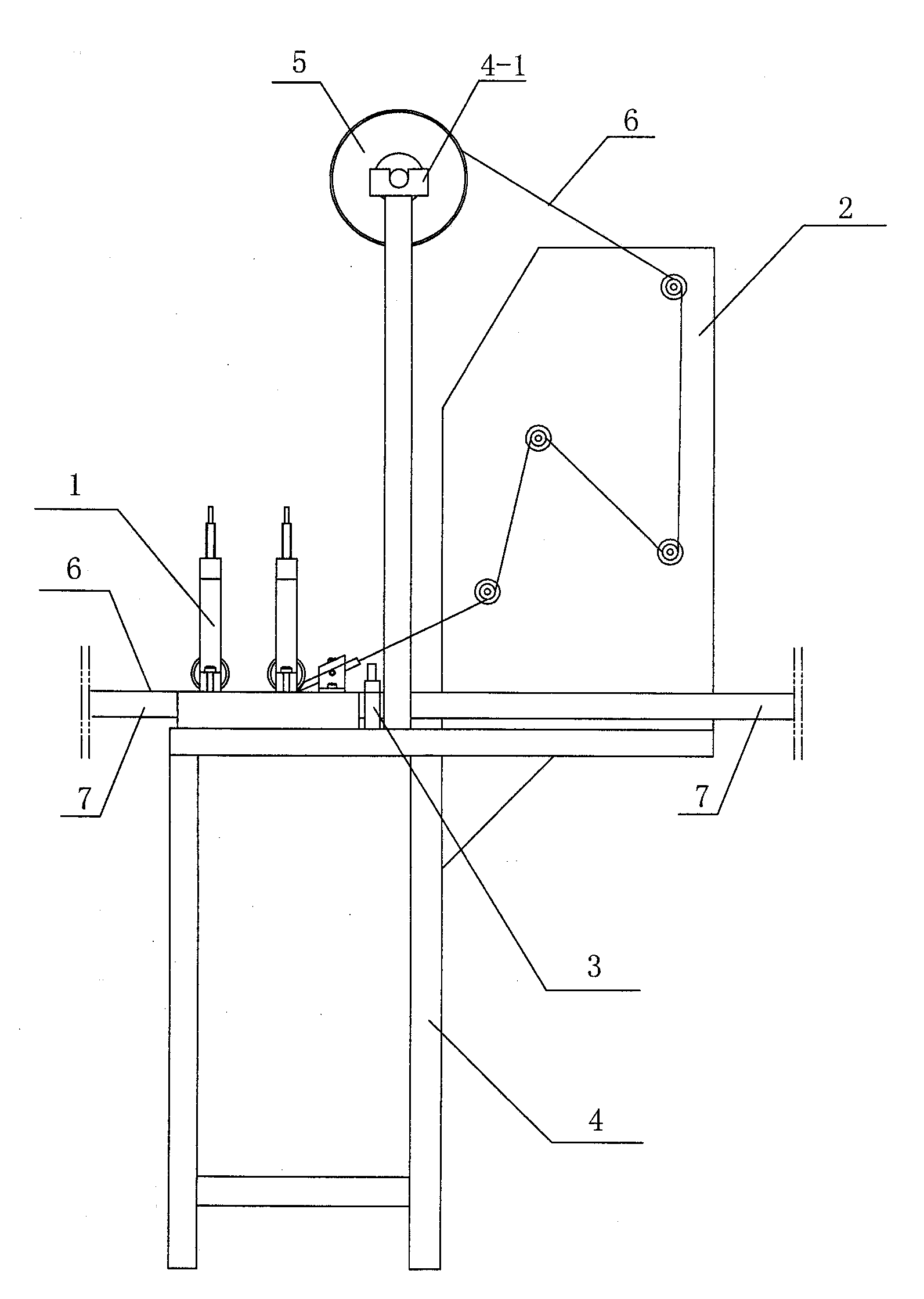

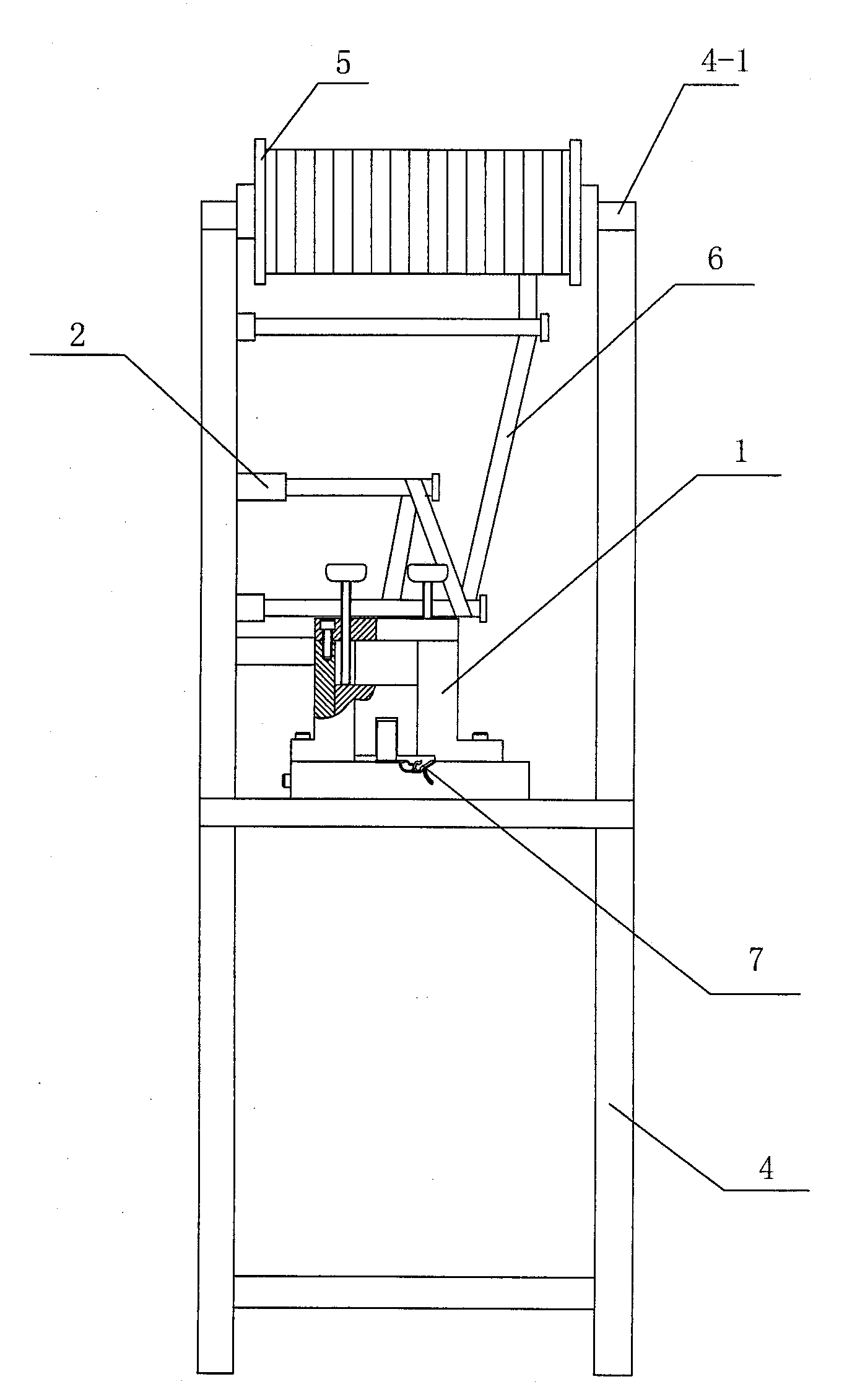

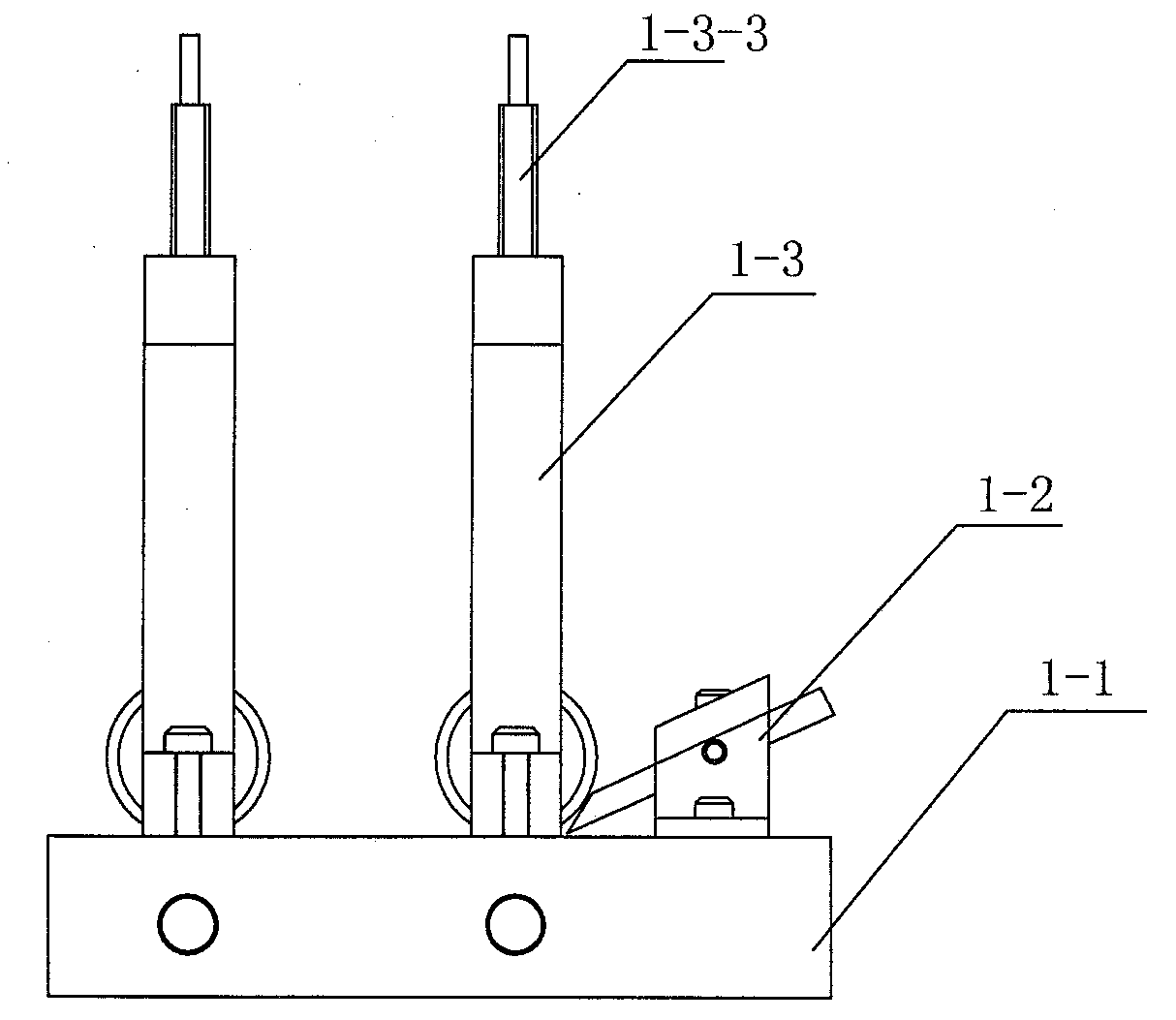

[0035] An online velvet pasting method for sealing strips, in which an online velvet pasting device for sealing strips is installed at the outlet of a vulcanization box for producing sealing strips, and the velvet tube 5 is installed on the bearing seat 4-1 at the top of the bracket 4 of the online velvet pasting device for sealing strips , then wind the velvet 6 on the velvet barrel 5 on the four guide wheels of the online velvet device guide wheel device 2, and enter the guide plate 1-2 on the online velvet device guide part 1-2 through the guidance of the guide wheels. Guide groove 1-2-3-1 on -3, and then pass through guide groove 1-2-3-1; Pull out the automobile instrument panel sealing strip 7 from the outlet end of the vulcanization box, and pass through the base plate of the online fleece pasting device The strip groove 1-1-1-3 on the 1-1-1 panel, together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com