Vehicle Steering Assembly and Its ATV

A technology for ATVs and vehicles. It is applied to steering mechanisms, steering rods, and vehicle components. It can solve problems such as difficult processing, joint plate deformation, and poor wheel steering consistency, so as to improve steering ability and maneuverability, and improve structure. Stability and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

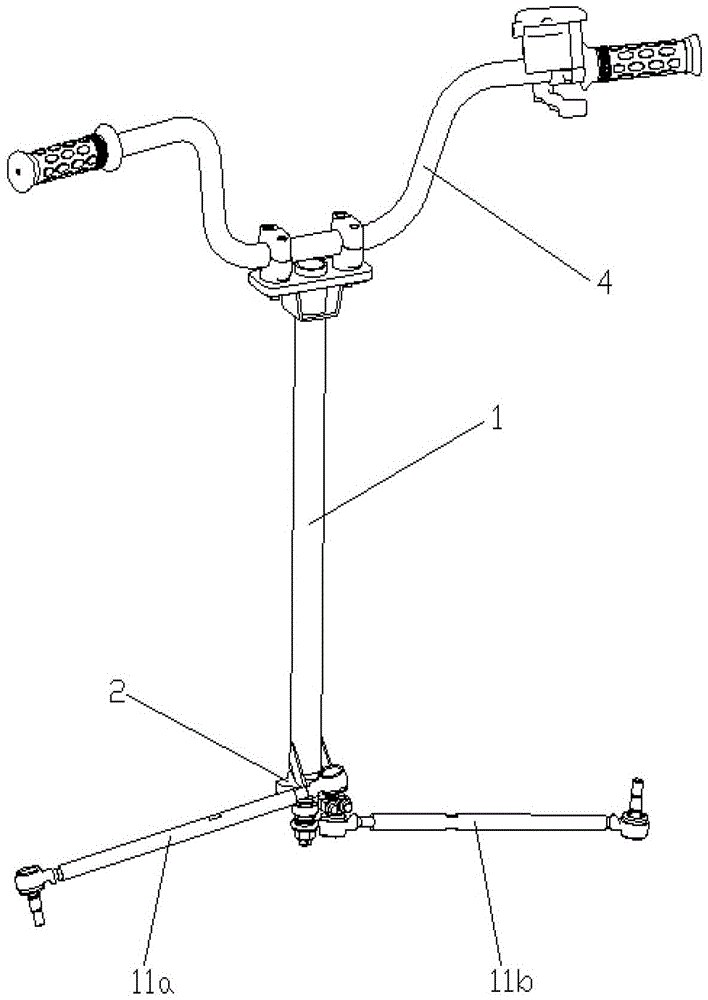

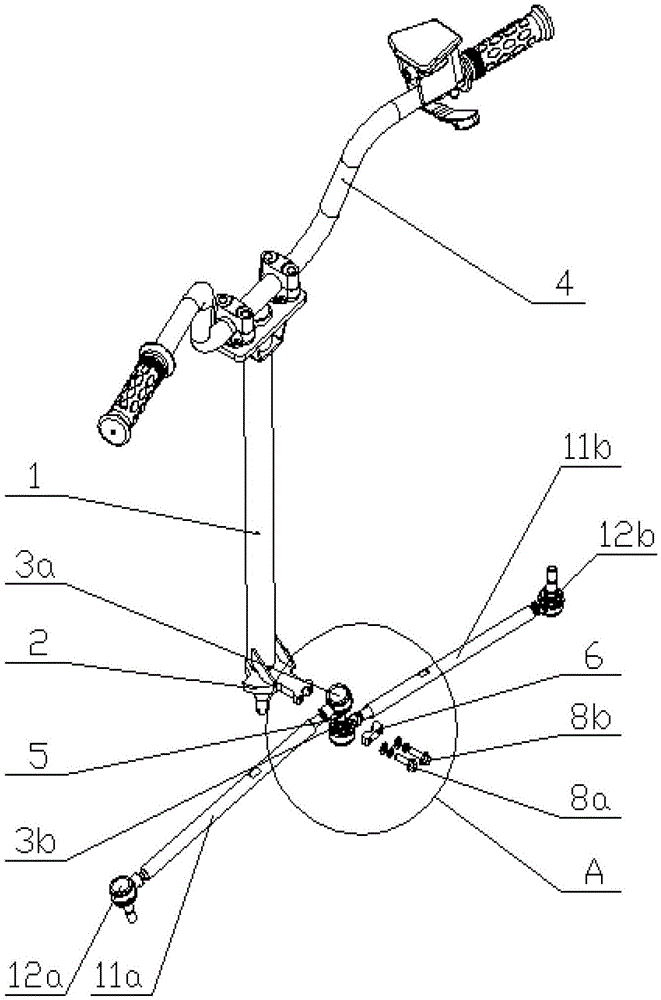

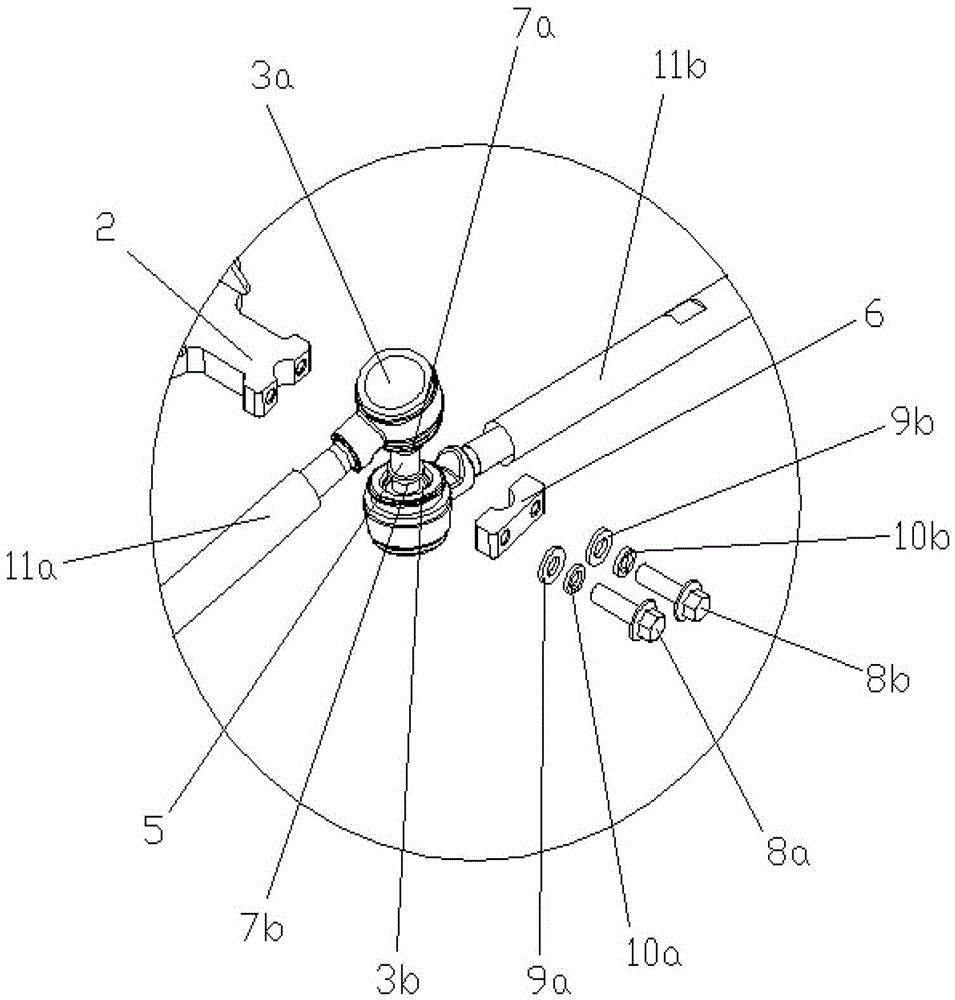

[0018] figure 1 It is a structural schematic diagram of the present invention, figure 2 is an exploded view of the present invention, image 3 for figure 2 The enlarged view at A in the middle is shown in the figure: the vehicle steering assembly of this embodiment includes a connecting plate 2 fixedly installed on the steering column 1 and two hinged ball joints fixed on the connecting plate 2 (Fig. marked as 3a and 3b respectively in the figure); the two hinged ball joints (marked as 3a and 3b respectively in the figure) are arranged on both sides of the connecting plate 2 along the axial direction of the direction column 1, that is, the two hinged ball joints (fig. 3a and 3b respectively) are arranged up and down, and the structure does not interfere with each other. The two hinged ball joints (marked 3a and 3b respectively in the figure) and the connecting plate 2 can be connected by existing connection methods such as welding or screw connection Fixed together, both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com