Disc type drier

A drying machine and disc-type technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problem that the condensed water cannot be discharged quickly and in large quantities, increase the load of the central axis of the drying equipment, and reduce the service life of the drying equipment and other problems, to achieve the effect of not being prone to water hammer effect, prolonging the service life and reducing the risk of bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

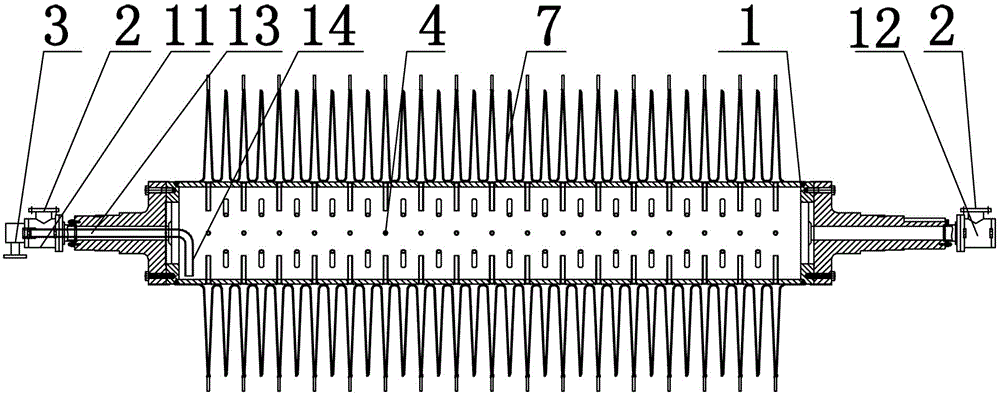

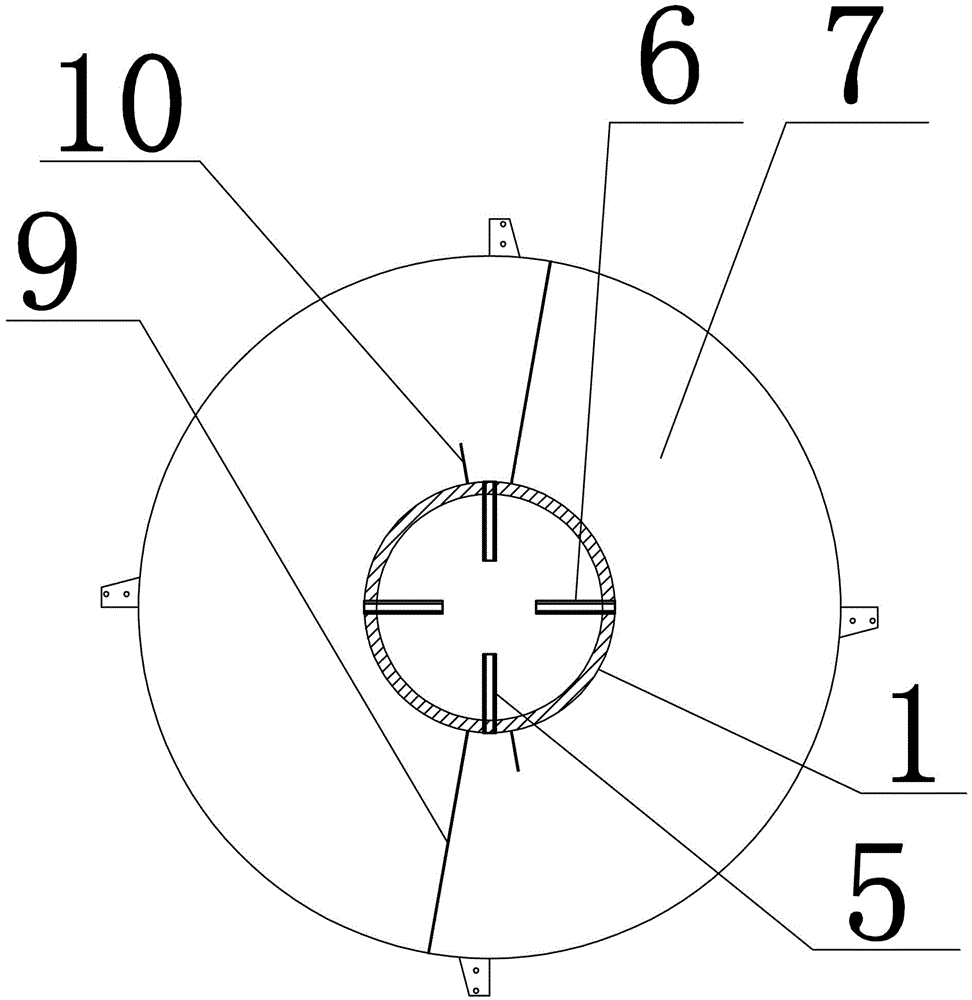

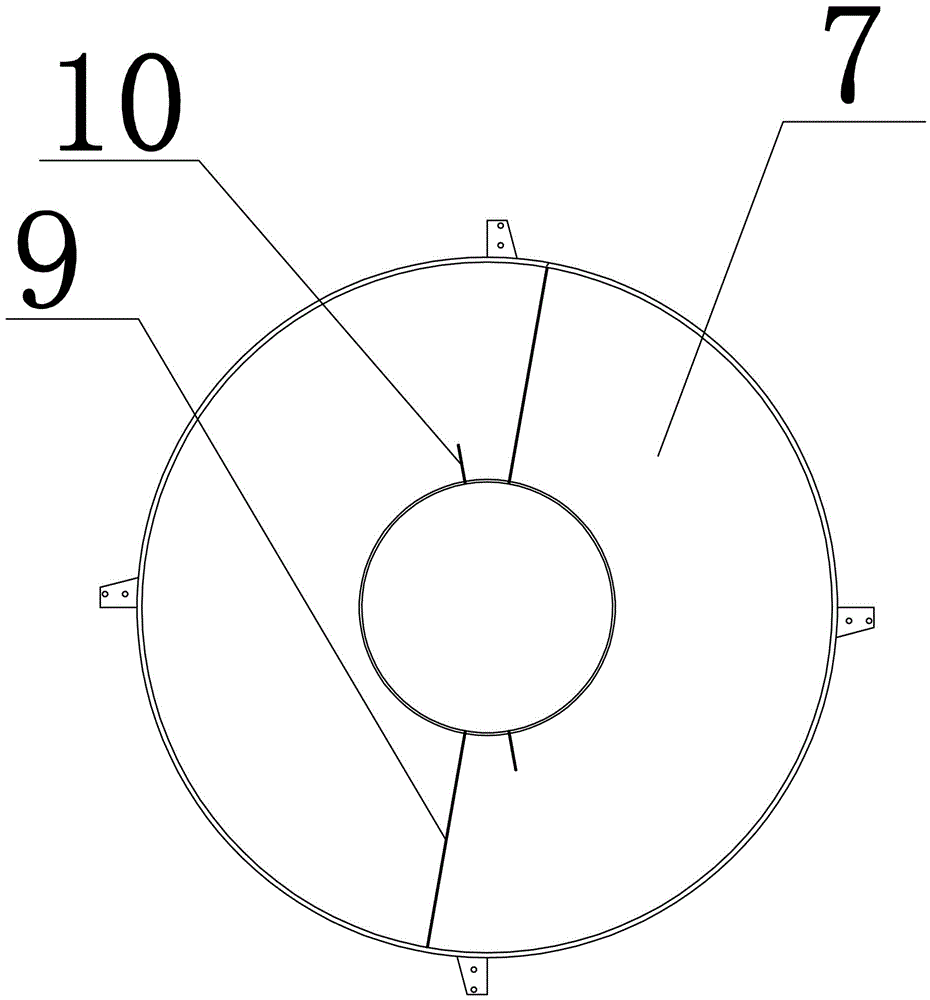

[0023] As shown in the figure, the present invention relates to a disc dryer, which includes a casing and a drying mechanism arranged in the casing. The drying mechanism includes a shaft 1 and shafts sleeved at both ends of the shaft 1. The shaft head is provided with a steam inlet 2 and a condensed water outlet 3; a number of guide tube groups 4 are evenly distributed on the shaft rod 1, and the guide tubes of each group of guide tube groups 4 are evenly distributed on the shaft On the same axial section of the rod 1, each set of guide tube groups 4 includes several condensate water guide tubes 5 and several steam guide tubes 6; There is a heat transfer plate 7, and the heat transfer plate 7 is welded by two disc-shaped sheets 8 facing each other; a number of deflector groups are arranged in the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com