Process for manufacturing well-drilling casing pipe of ice layer

A manufacturing process and drilling casing technology, which is applied in the field of ice layer drilling casing manufacturing technology, and can solve problems such as poor sealing effect of casing, environmental pollution, drilling fluid leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

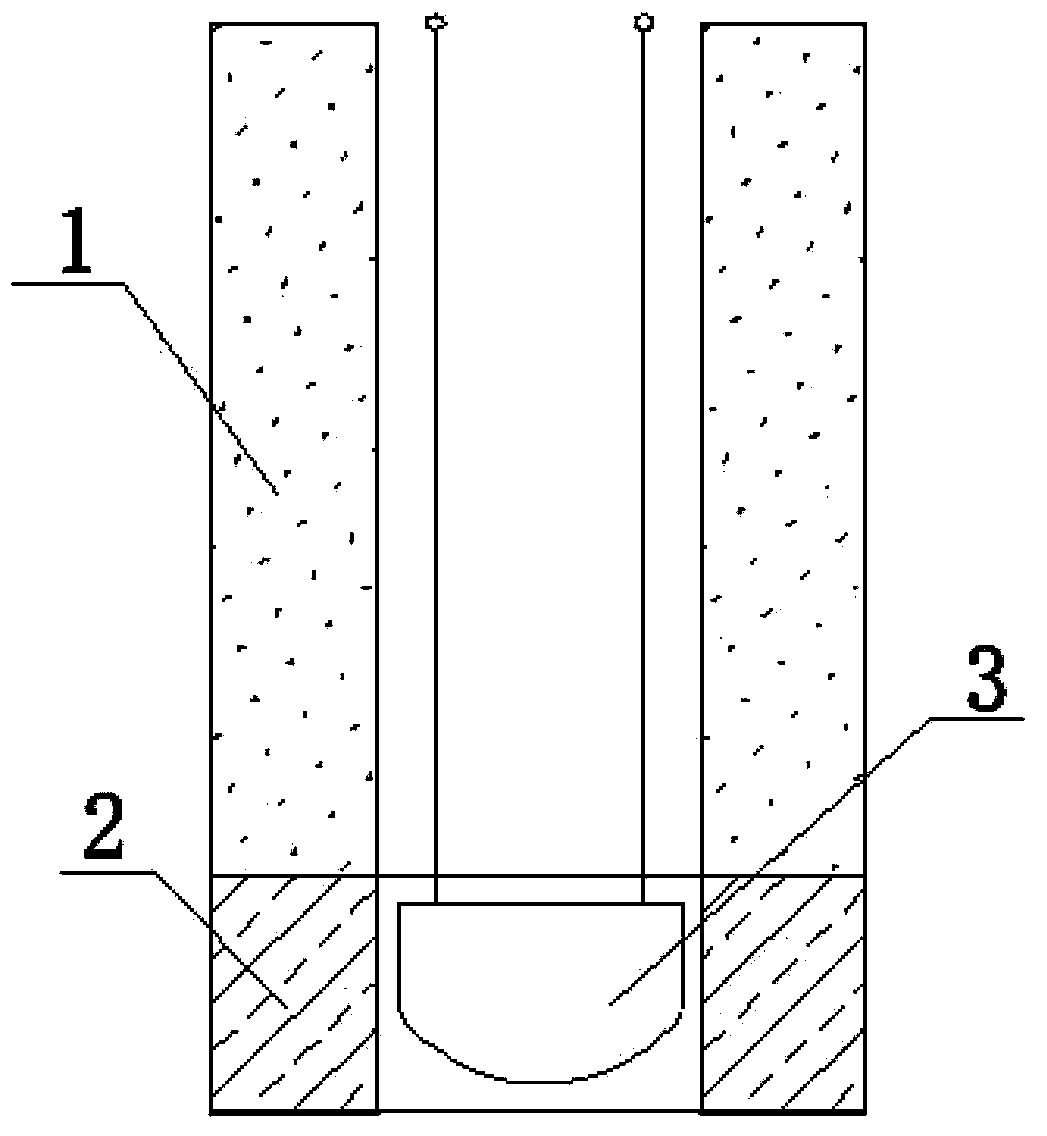

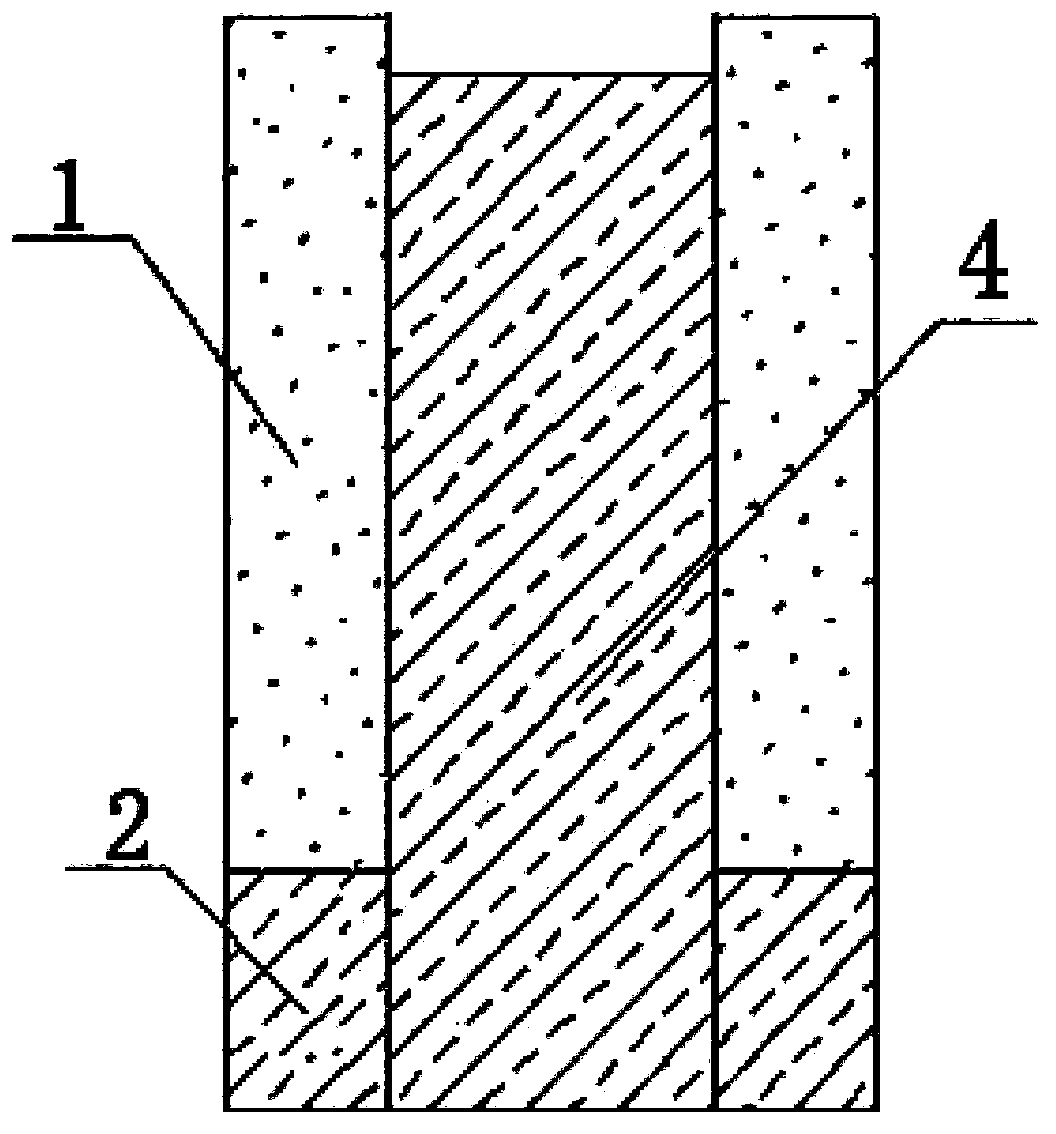

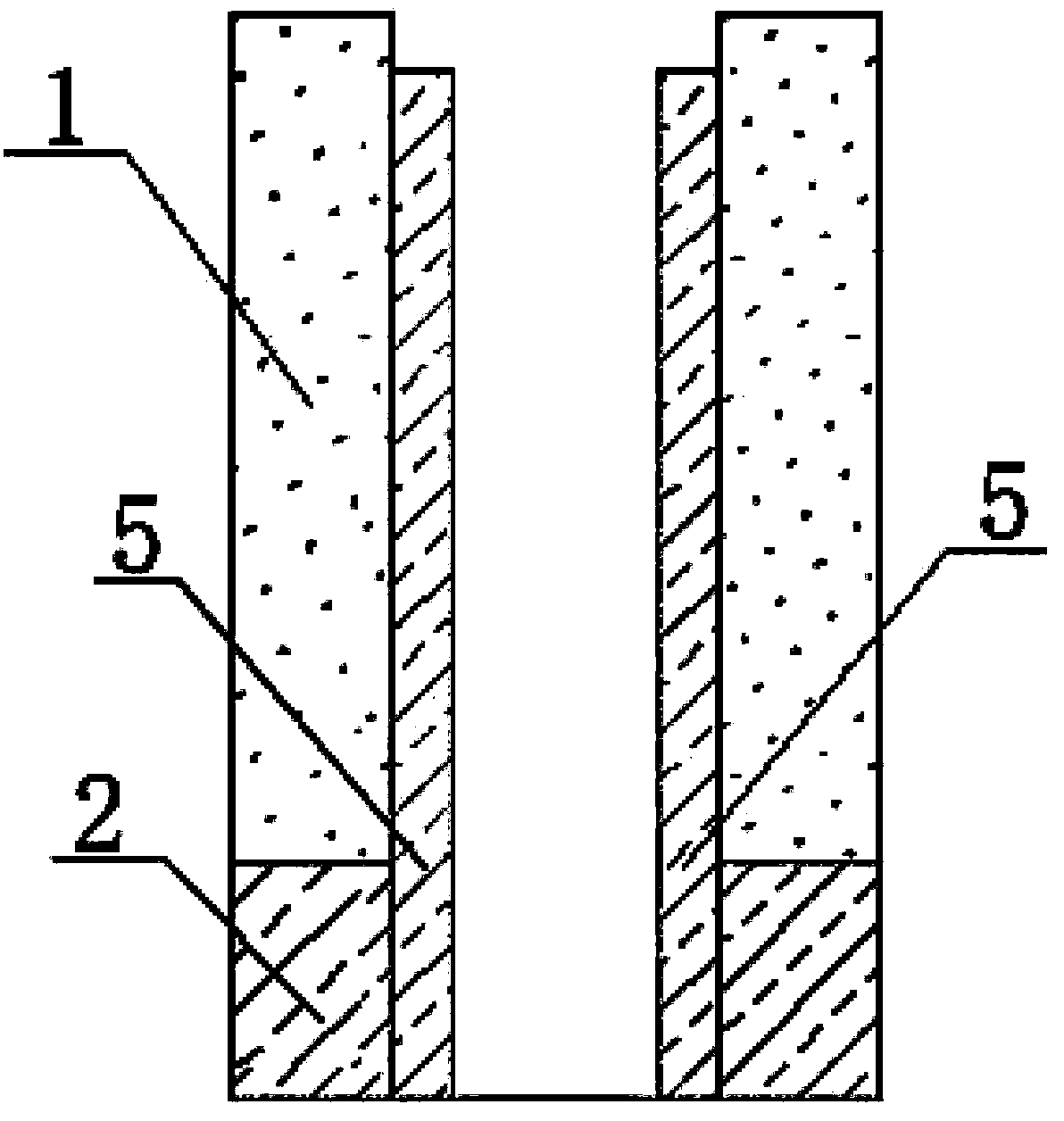

[0014] The structure of the present invention is illustrated in conjunction with the accompanying drawings. Figure 1 ~ Figure 3 Middle, 1. Snow accumulation-snow layer; 2. Ice layer; 3. Hot-melt bit; 4. Icicle; 5. Ice casing. Before conducting conventional ice drilling, first use the hot-melt drill bit to drill from the snow-snow layer to the ice layer. During the drilling process of the hot-melt drill bit, the snow-snow layer drilled by the drill bit melts into water, and the The hot-melt bit is raised from the bottom of the well to the surface, such as figure 1 Shown; After the hot-melt drill bit stops working, the water that melts into the snow-snow layer freezes into icicles and fuses with the ice layer into an impermeable whole, as figure 2 Shown; Drilling operations are carried out on the ice column (drilling diameter is smaller than the diameter of the ice column) to form an ice casing, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com