Minimally-invasive non-excavation pipe jacking and pull technology

A trenchless, top-pulling technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc., can solve problems such as increasing costs, affecting traffic, and affecting people's livelihood, and achieving the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

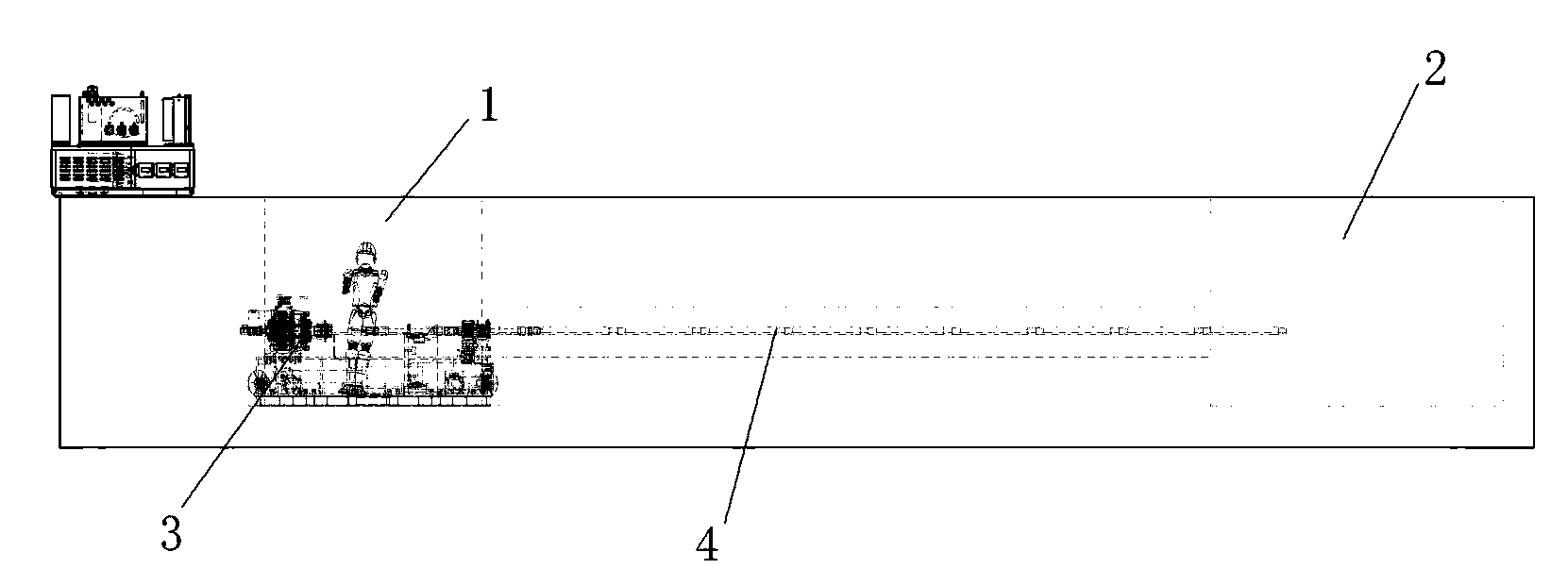

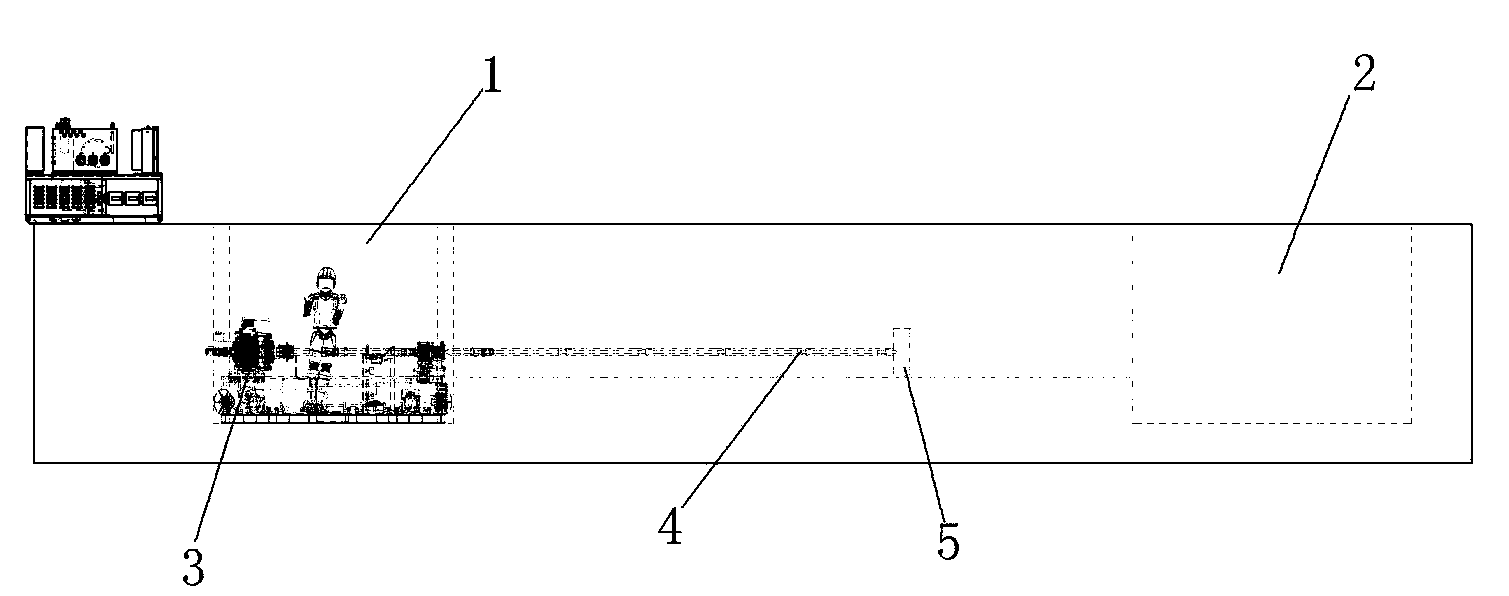

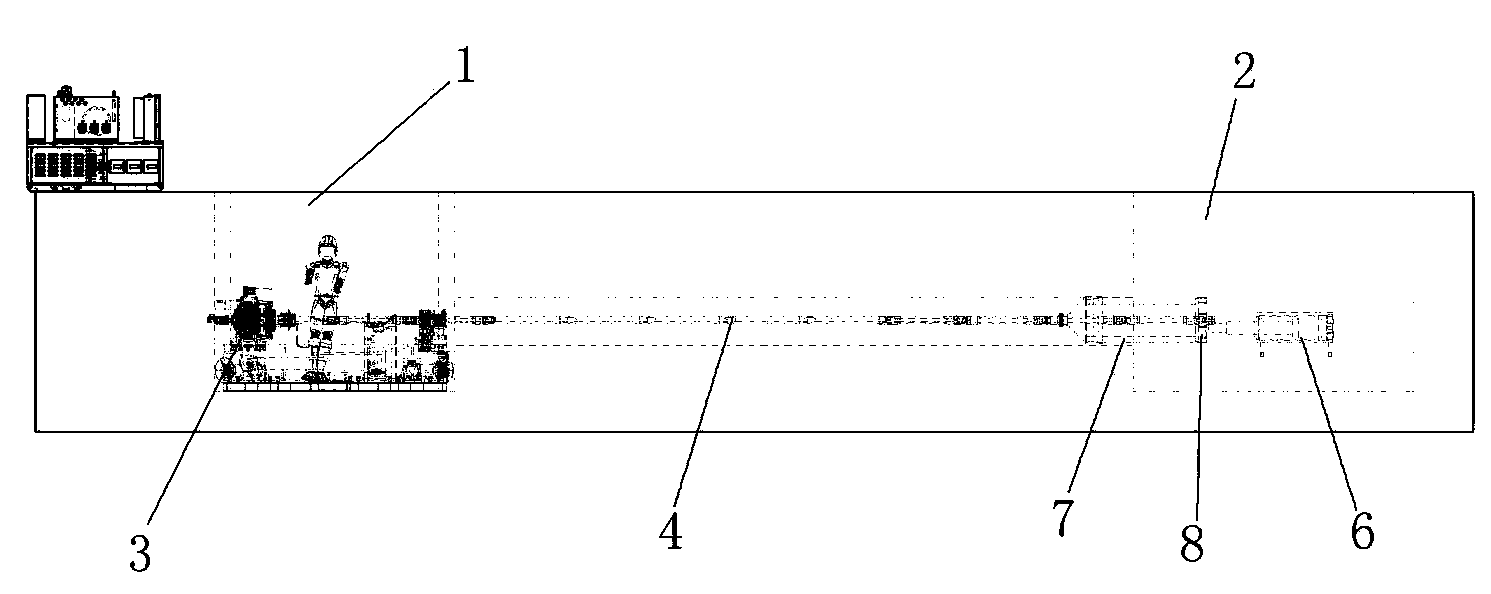

[0016] This embodiment provides a minimally invasive non-excavation pipe jacking process, and its work flow is as follows Figure 1-3 shown, including the following steps:

[0017] Step 1, digging a working well 1 and a receiving well 2. A working well 1 and a receiving well 2 are respectively dug at both ends of the section where pipelines need to be laid. After digging, the working well 1 and the receiving well 2 are reinforced with channel steel.

[0018] Step 2: Drill the pilot hole. Such as figure 1 , first erect the minimally invasive trenchless drilling equipment 3 in the working well, and fix it, then start the minimally invasive trenchless drilling equipment 3, and use the pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com