Oxaliplatin wet product drying device

A technology of oxaliplatin and drying equipment, which is applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of workshop pollution, organic solvent explosion, allergies to oxaliplatin personnel, etc., to reduce pollution, Work process safety, effect of preventing arc phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

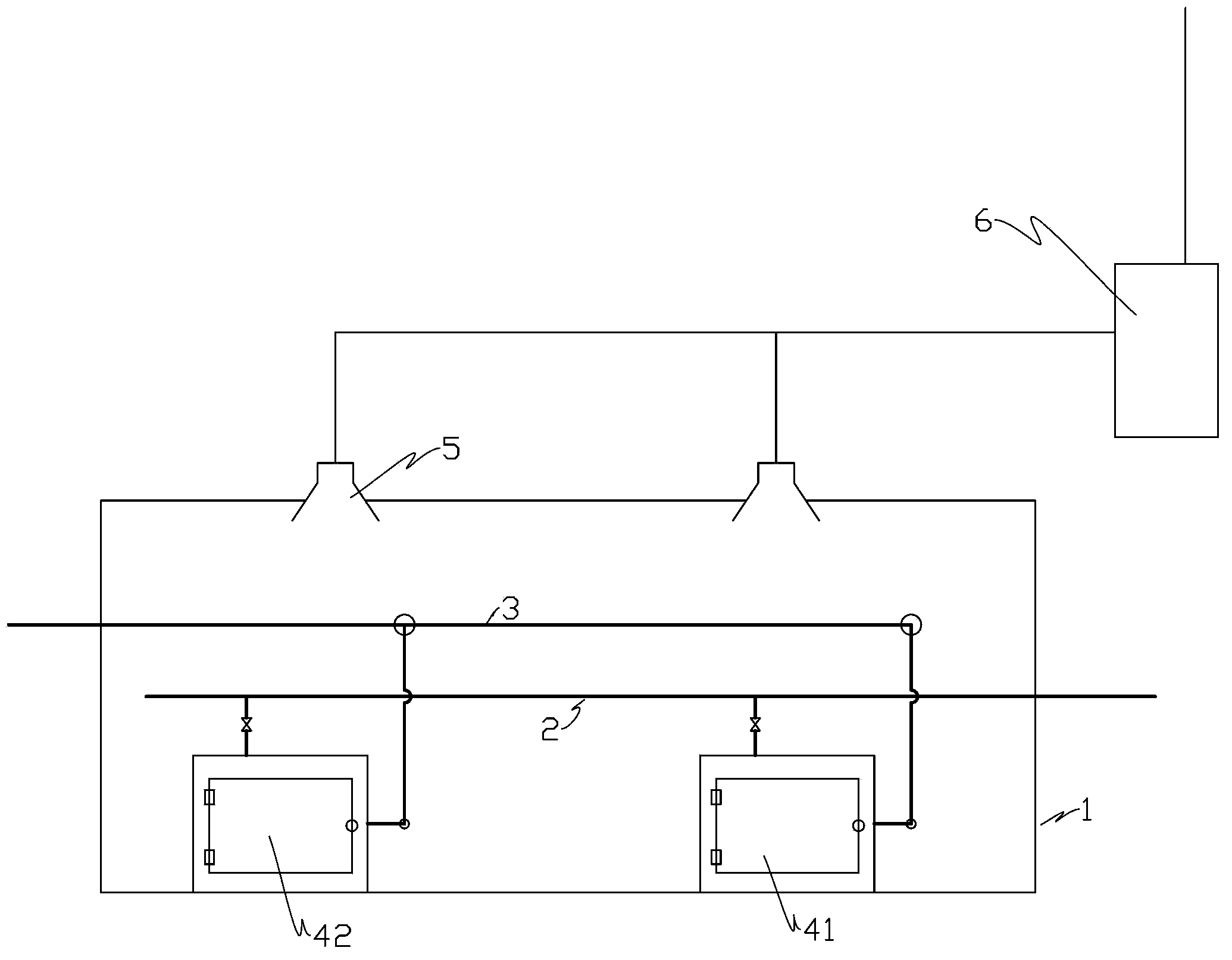

[0010] Such as figure 1 as shown,

[0011] The vacuum drying oven is specially designed for drying heat-sensitive, easily decomposed and easily oxidized substances. When working, it can maintain a certain degree of vacuum in the working room and can fill the interior with inert gas, especially for some items with complex components. Fast drying, using intelligent digital temperature regulator for temperature setting, display and control.

[0012] The transformation method is as follows: add a closed shell 1, adopt aluminum-plastic door and window structure, use glass around it to form a perspective window, and set a sliding door body on the front, which can be operated conveniently. In the inner space of the housing 1, there are two parallel evacuation pipes 2 and explosion-proof electrical pipes 3, and the evacuation pipes are evacuated to the vacuum drying box through the valves to meet the working conditions. The explosion-proof electrical pipeline 3 can be made of galvan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com