Energy-saving type material drying system

A drying system and energy-saving technology, applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problems of improper drying flow, unused, environmental pollution and other problems of materials, so as to reduce heating power consumption and ventilation power consumption. , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

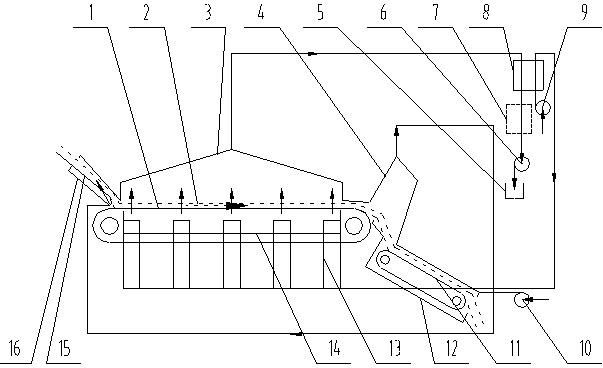

[0026] Example 1, such as figure 1 As shown, the material flow 2 reaches the perforated mesh conveyor belt device 1 through the wet material preheating box 16, is heated and dried by the high-temperature air from the high-temperature dry air distribution box 14 during the forward conveying process, and then leaves the perforated mesh conveyor belt device 1. The conveyor belt device 1 enters the dry material cooling box 12 . The dry material is cooled by the fresh air sent by the dry material cooling fan 10 during the continuous conveyance along the conveyor belt 11 . After that, the dry material leaves the cooling box 12 and leaves the drying system to wait for boxing. The air blown out by the dry material cooling fan 10 is collected by the dry material hot air collection device 4 after being heated by the dry material and transported to the wet material preheating box 16, and the material flow is preheated and heated through the mesh feeding plate 15 with holes. Leave the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com