Gas flowmeter and application method thereof

A gas flow meter and airflow direction technology, which is applied to the volume/mass flow rate generated by mechanical effects, and the direction of fluid flow detection by measuring differential pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

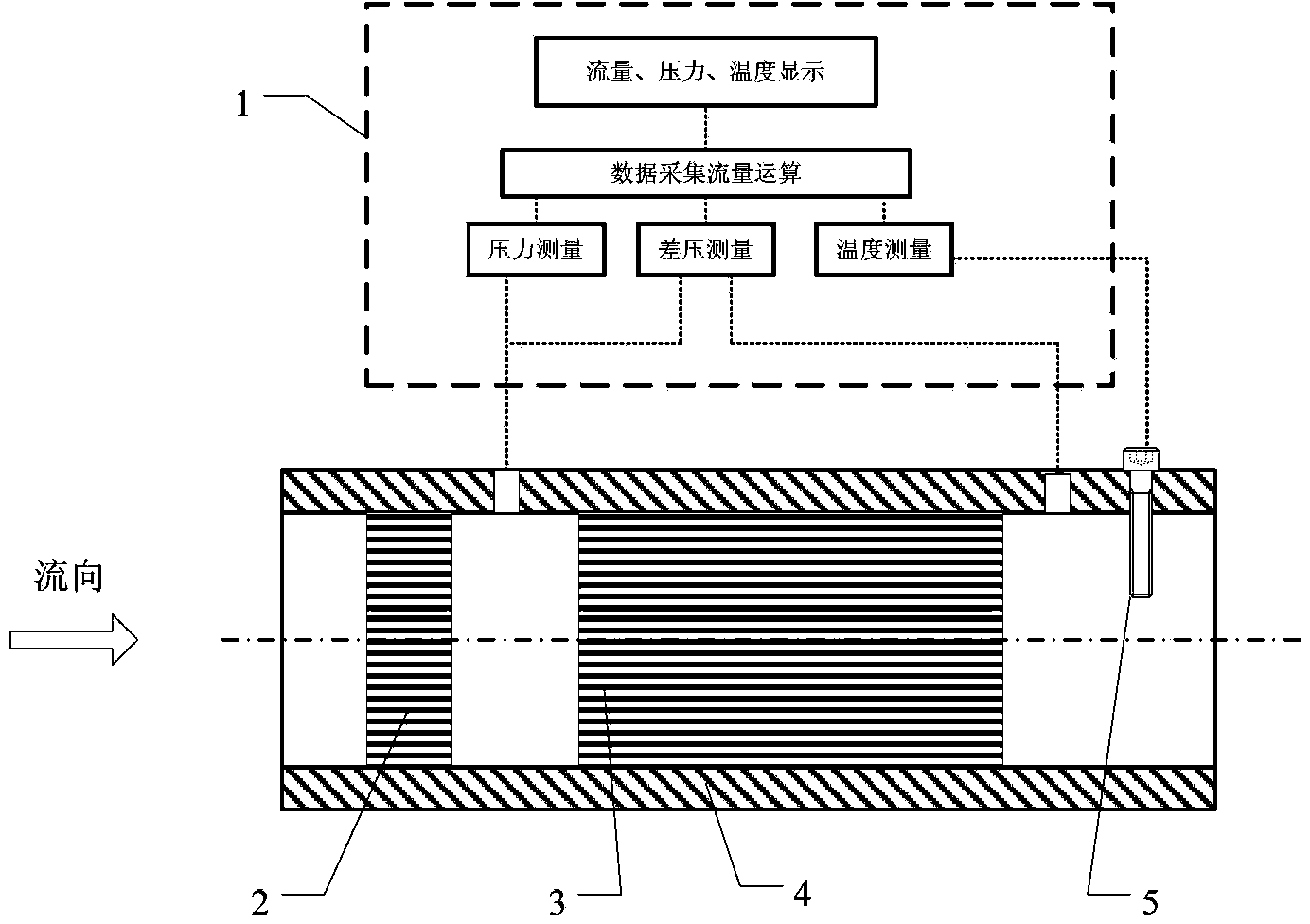

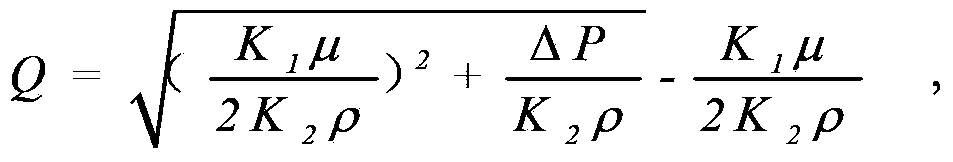

[0029] The working principle of the gas flow meter of the present invention is as follows: figure 1 Shown: The gas to be measured flows through the flowmeter, first passes through the diversion filter element, filters out the impurities in the gas, and rectifies the airflow to make the flow stable. When the air flow passes through the laminar flow generating body, due to the frictional resistance, pressure loss occurs at both ends of it. When the Reynolds number of the fluid flow is less than 2300, the pressure loss is proportional to the gas flow rate. which is

[0030] Flow rate formula: v - = c μ · ΔP

[0031] In the formula: - the average velocity of the fluid;

[0032] ΔP - the pressure difference at both ends of the laminar flow generator;

[0033] μ - dynamic viscosity of fluid medium

[0034] c—Constants related to geometrical dimensions.

[0035] Flow f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com