Arc-extinguishing material for fuse and preparation method of arc-extinguishing material

An arc-extinguishing material and fuse technology, applied in the manufacture of fuses, electrical components, circuits, etc., can solve the problems of fast heat dissipation, rough surface of quartz sand, and large thermal conductivity, so as to improve the breaking capacity and suppress the formation and diffusion of arcs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

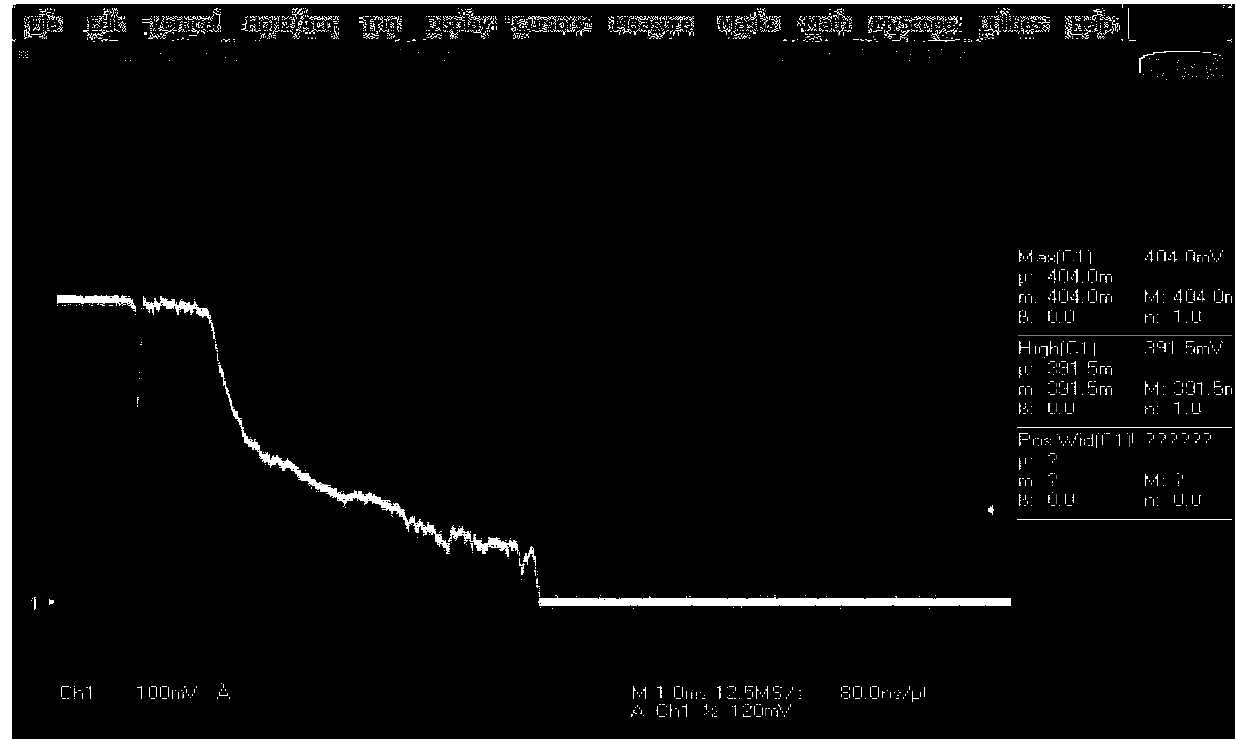

Image

Examples

Embodiment 1

[0034] An arc extinguishing material for a fuse comprises 200 parts by weight of microcrystalline silicon dioxide (1000 mesh), 46 parts of microcrystalline cellulose, 72 parts of silicone resin adhesive and 200 parts of water.

[0035] A method for preparing the arc extinguishing material for the fuse; comprising the following preparation steps:

[0036] Mix the amount of microcrystalline silicon dioxide, microcrystalline cellulose, silicone resin adhesive and water, knead into a dough after mixing, and then use extrusion equipment (temperature is 5 ~ 30 ° C, pressure is 5 ~8 kg) extrude the above dough mixture, and finally roll into a ball to obtain the arc extinguishing material.

Embodiment 2

[0038] An arc extinguishing material for a fuse, comprising 200 parts by weight of amorphous silicon dioxide (700 mesh), 50 parts of microcrystalline cellulose, 68 parts of silicone resin adhesive and 300 parts of water.

[0039] The method for preparing the arc extinguishing material for the fuse is the same as that in Example 1.

Embodiment 3

[0041] An arc-extinguishing material for a fuse, comprising 250 parts by weight of silicon dioxide (including 50 parts of 1000-mesh microcrystalline silicon dioxide, 200 parts of 700-mesh amorphous silicon dioxide), 45 parts of microcrystalline cellulose, modified 70 parts of permanent bisphenol A / F liquid epoxy resin and 250 parts of water.

[0042] The method for preparing the arc extinguishing material for the fuse is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com