LED module and manufacturing method thereof

A technology of LED modules and manufacturing methods, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of affecting the luminous performance of products, poor heat dissipation performance, and short service life, and achieve strong heat dissipation performance, long service life, The effect of small thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

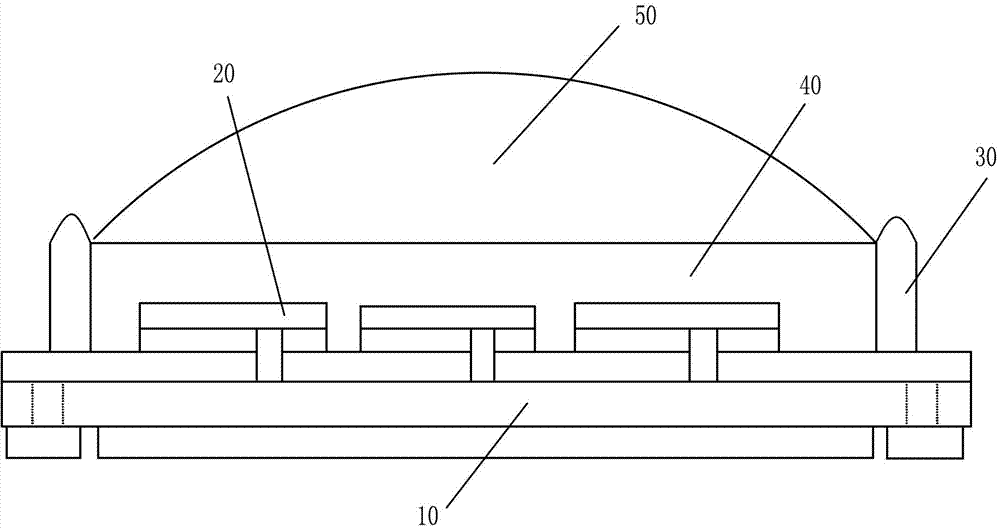

[0034] Flip-chip step: the LED chip 20 is flip-chip welded on the metal sheet of the high thermal conductivity ceramic substrate 10 by eutectic soldering, and a plurality of LED chips 20 are evenly arranged at predetermined intervals and predetermined orientations. Preferably, there are multiple LED chips, and a plurality of LED chips 20 are injected with dams 30 around the periphery. As an implementation, the flipping step also includes two sub-steps:

[0035] Soldering sub-step: coating flux on the surface of the metal sheet of the high thermal conductivity ceramic substrate 10, adhering the LED chip 20 to the metal sheet coated with flux; and

[0036] Soldering sub-step: reflow the high thermal conductivity ceramic substrate 10 adhered with the LED chip 20 through a reflow furnace at a predetermined temperature. Wherein, the predetermined temperature is 100°C to 360°C.

[0037] Injection step: injecting the dam 30 on the periphery of the LED chip;

[0038] Coating step: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com