A kind of polycarboxylic acid dispersant and its preparation method and application

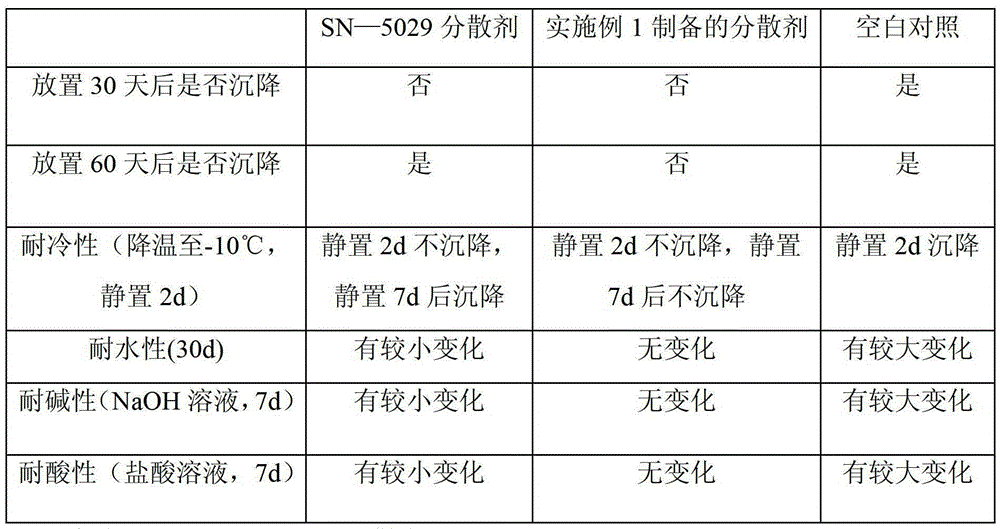

A technology of dispersant and polycarboxylic acid, which is applied in chemical instruments and methods, dyeing polymer organic compound treatment, fibrous filler, etc., can solve the problems of unsatisfactory dispersion effect and comprehensive performance, and achieve low cost and improved water resistance , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of polycarboxylic acid dispersant, comprising the following steps:

[0031] (1) In a 250mL four-necked flask equipped with a stirrer, dropping funnel, thermometer and reflux condenser, add 1.0 parts of crotonic acid, 1.1 parts of sodium methacrylate, 0.6 parts of maleic acid, and 0.03 parts of sulfurous acid Sodium hydrogen and 25 parts of water were stirred and dissolved, and the temperature was raised to 75°C to obtain a mixed solution;

[0032] (2) Slowly add ammonium persulfate aqueous solution (containing 0.11 parts of ammonium persulfate) dropwise to the mixed solution obtained in step (1), and the speed is controlled at 1 drop / second. After the dropwise addition is completed, stop the reaction after 3 hours of insulation reaction, and obtain The main product of dispersant;

[0033] (3) After cooling the main product of the dispersant obtained in step (2) to 40°C, adjust the pH value of the reaction system with a NaOH solution with a mass con...

Embodiment 2

[0039] A preparation method of polycarboxylic acid dispersant, comprising the following steps:

[0040] (1) In a 250mL four-neck flask equipped with a stirrer, dropping funnel, thermometer and reflux condenser, add 2.0 parts of crotonic acid, 1.6 parts of sodium methacrylate, 0.8 parts of maleic acid, and 0.04 parts of sulfurous acid Sodium hydrogen and 32 parts of water were stirred and dissolved, and the temperature was raised to 78°C to obtain a mixed solution;

[0041](2) Slowly add ammonium persulfate aqueous solution (containing 0.14 parts of ammonium persulfate) dropwise to the mixed solution obtained in step (1), and the speed is controlled at 1 drop / second. After the dropwise addition is completed, the reaction is stopped after the insulation reaction for 3 hours to obtain The main product of dispersant;

[0042] (3) After cooling the main product of the dispersant obtained in step (2) to 44°C, adjust the pH value of the reaction system with a NaOH solution with a ma...

Embodiment 3

[0048] A preparation method of polycarboxylic acid dispersant, comprising the following steps:

[0049] (1) In a 250mL four-neck flask equipped with a stirrer, dropping funnel, thermometer and reflux condenser, add 2.5 parts of crotonic acid, 1.8 parts of sodium methacrylate, 1.0 parts of maleic acid, and 0.05 parts of sulfurous acid Sodium hydrogen and 28 parts of water were stirred and dissolved, and the temperature was raised to 80°C to obtain a mixed solution;

[0050] (2) Slowly add ammonium persulfate aqueous solution (containing 0.18 parts of ammonium persulfate) dropwise to the mixed solution obtained in step (1), and the speed is controlled at 1 drop / second. After the dropwise addition is completed, the reaction is stopped after the insulation reaction for 3 hours to obtain The main product of dispersant;

[0051] (3) After cooling the main product of the dispersant obtained in step (2) to 48°C, adjust the pH value of the reaction system with a NaOH solution with a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com