Vibrating chip-removing device of engine cylinder head

A technology of engine cylinder head and vibration mechanism, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of increasing the work intensity of operators, engine failure, and affecting the normal driving of vehicles, etc., to achieve improvement Final cleanliness, reduced labor intensity, and guaranteed normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

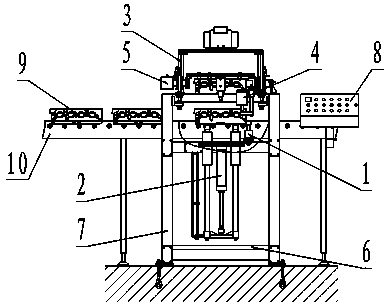

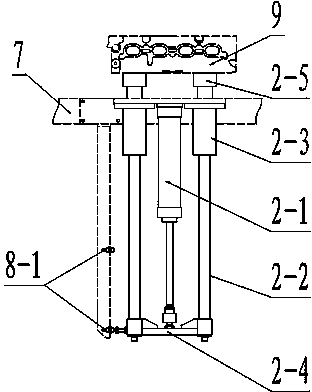

[0025] Referring to Fig. 1, the present invention comprises workpiece movement limit mechanism 1, workpiece elevating mechanism 2, workpiece vibration mechanism 3, workpiece turning mechanism 5, frame 7 and PLC control system 8, and described frame 7 is fixed on the level ground Frame structure, it is equipped with the workpiece conveying roller table 10 of the cylinder head processing line, the workpiece movement limit mechanism 1 and the lifting mechanism 2 are installed on the frame middle beam 7-2, the workpiece vibration mechanism 2 and the machine Columns 7-3 on both sides of the frame are assembled, and the workpiece turning mechanism 5 is assembled with the workpiece vibrating mechanism 3.

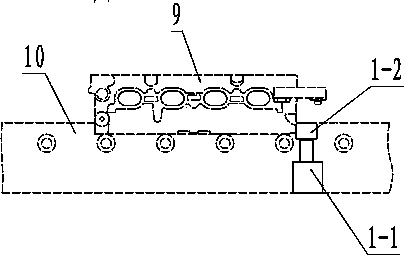

[0026] See Figure 1, figure 2 , the workpiece movement limit mechanism 1 of the present invention includes a workpiece movement limit cylinder 1-1 and a workpiece stopper 1-2, and the workpiece movement limit cylinder 1-1 is fixed on the frame middle beam 7-2, and the workpiece A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com