Backfill type friction stir welding method and device

A technology of friction stir and welding method, which is applied in the direction of welding equipment, non-electric welding equipment, metal processing equipment, etc., and can solve the problem that the keyhole after welding cannot be eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

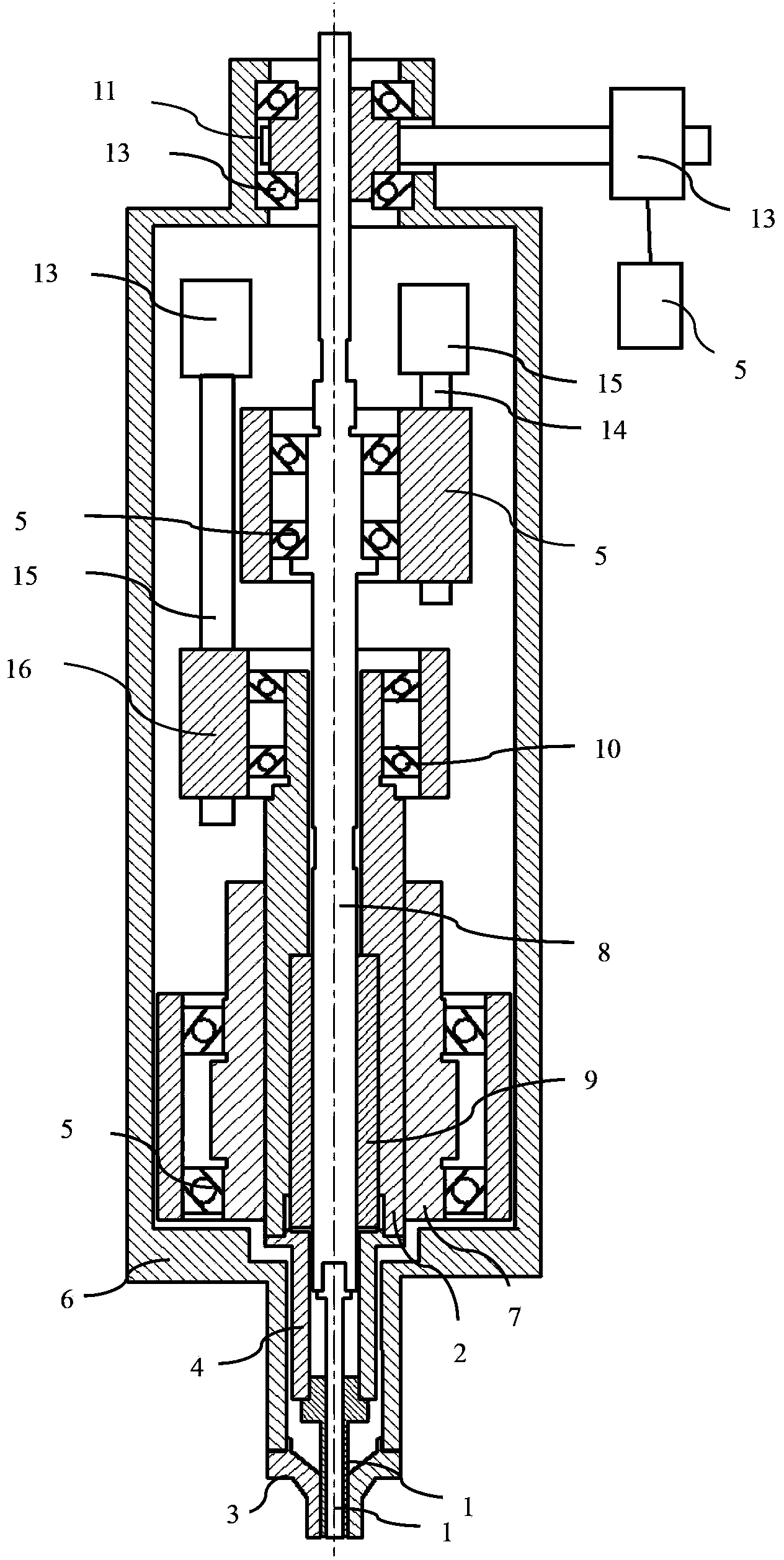

[0023] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

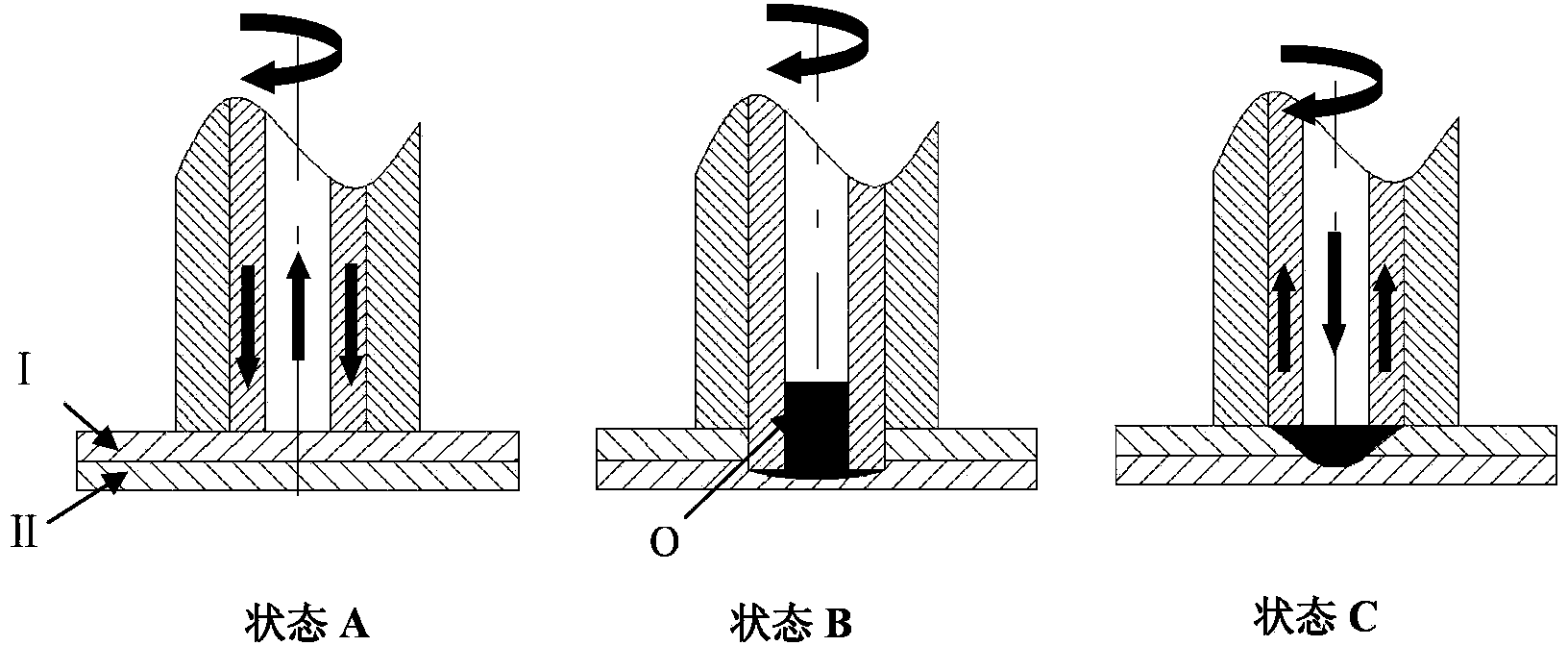

[0024] See attached Figure 3-4 As shown, this kind of backfilling friction stir welding method is characterized in that: the steps of the method are:

[0025] (1) Stirring pin 1 and shaft shoulder 2 of the stirring head can move in the opposite direction along the axial direction while rotating together, and the shaft shoulder 2 moves downward into the weld, and at the same time, stirring pin 1 moves along with the shaft shoulder 2 synchronously. The axial direction moves in the opposite direction, and the lower end surface of the jacket 3 of the stirring head is pressed against the welding seam position;

[0026] (2) During the welding process, the stirring needle 1, the shaft shoulder 2 and the jacket 3 of the stirring head remain in a relative position. Under the rotation and extrusion of the shaft shoulder 2, the weldme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com