Plate group welding tooling

A technology of welding tooling and pole group, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to ensure the alignment of the positioning plate, difficulty in opening and closing molds, and high labor intensity, and achieve improvement Labor efficiency, easy to master, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

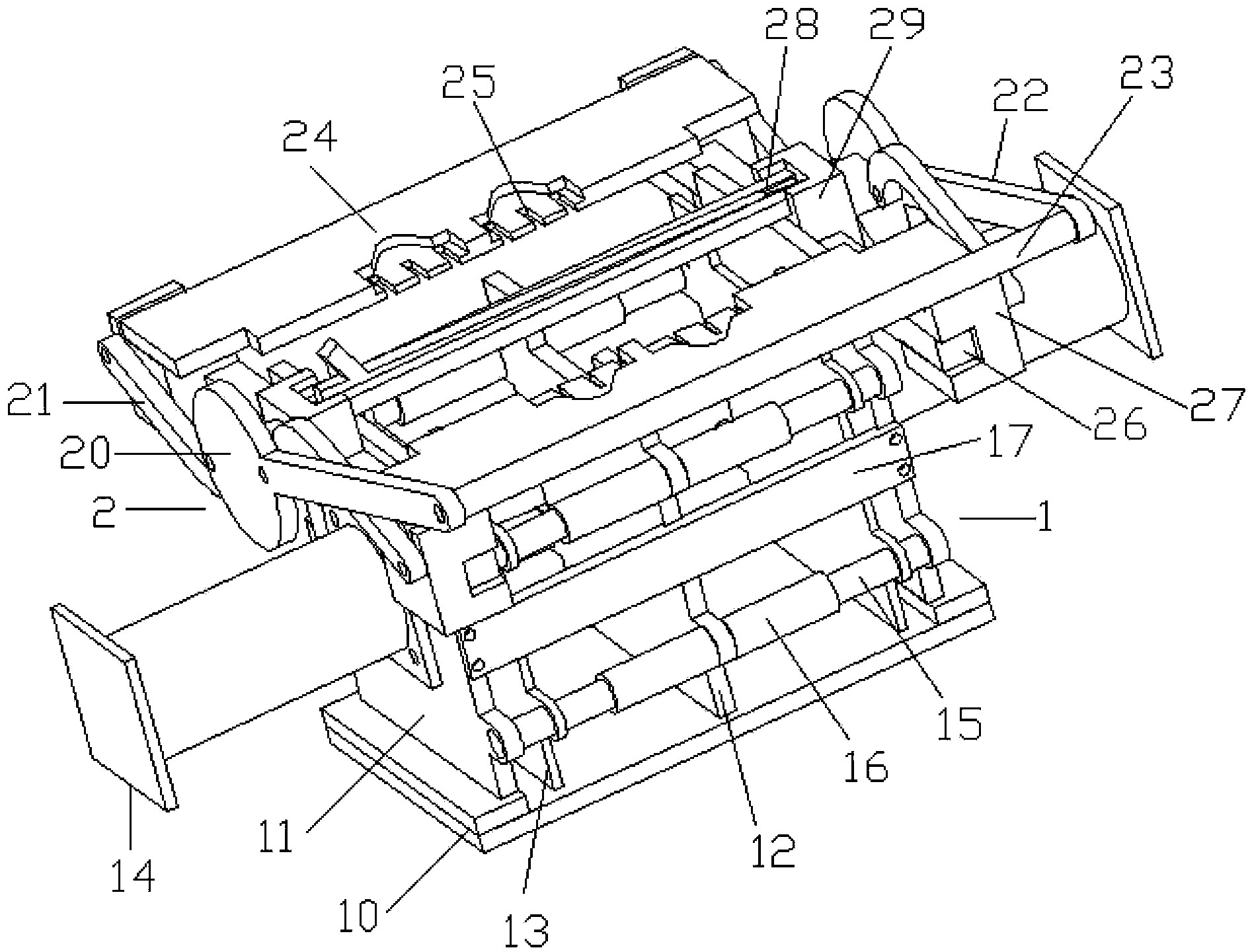

[0018] Combine below figure 1 The pole group welding tool of the present invention is specifically described.

[0019] The pole group welding tool includes a mold box 1, the mold box 1 includes a bottom plate 10, side plates 11 are vertically fixed on the left and right sides of the bottom plate 10, and a neutral plate 12 is provided in the middle of the mold box to separate the inner cavity of the mold box Place mold cavities for the left and right pole groups, the left and right sides of the mold box are provided with push plates 13 that can move laterally so as to cooperate with the neutral plate to clamp or loosen the pole groups, and the left and right sides of the side plates are installed A cylinder 14 is arranged to drive the push plate 13 to move laterally. The upper and lower sides of the front and rear ends of the side plates are respectively provided with a sliding column 15, and the push plate slides along the sliding column to make the movement of the pushing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com