Mobile type bearing placing frame

A rack and mobile technology, which is applied in the field of mobile bearing racks, can solve the problems of low efficiency and high labor intensity of manual handling of main bearings, and achieve long service life, labor-saving access and placement, and reduce the work intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

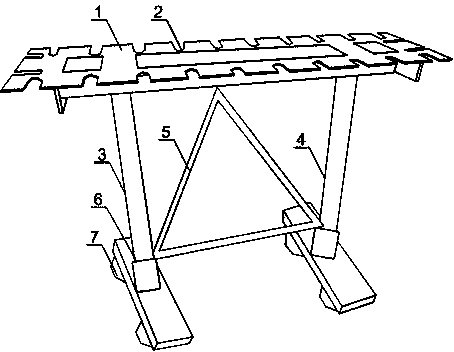

[0020] Such as figure 1 As shown, this embodiment includes a supporting frame and a hanging board 1, the bottom of the hanging board 1 is connected with the supporting frame, a plurality of U-shaped notches 2 are symmetrically arranged around the surrounding of the hanging board 1, and a lifting device is installed on the supporting frame. Mechanism, the bottom of support frame is equipped with a plurality of universal wheels 7. The hanging plate 1 is welded with the bottom of the supporting frame to form a whole, and a plurality of U-shaped notches 2 are symmetrically arranged around the hanging plate 1 for engaging and fixing the main bearing, so as to provide a stable suspension for the main bearing. The frame structure and the three-dimensional suspension reduce the occupation of the ground area by multiple main bearings; the lifting mechanism installed at the bottom of the support frame can freely adjust the height of the hanging plate 1 from the ground when the main bear...

Embodiment 2

[0023] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, the support frame includes a leg A3 and a leg B4, and the lifting mechanism is installed at the bottom of the leg A3 and the leg B4, and the leg A3 and the leg B4 are connected by a tripod 5 . According to the stability of the triangle, a triangle fixing frame 5 is installed between the supporting feet A3 and the supporting feet B4, which improves the stability of the supporting frame; the separately arranged supporting feet A3 and B4 can share the bearing capacity on the hanging board 1; the supporting feet A3 Lifting mechanisms are respectively provided at the bottom of the leg and the leg B4. When the main bearing needs to be stored or taken, the two lifting mechanisms can be adjusted at the same time to adjust the height of the hanging plate 1, which is fast and labor-saving.

Embodiment 3

[0025] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, the distance between the U-shaped notches 2 is 10-15 cm. In order to avoid the mutual extrusion between the main bearings when placed, a certain distance is set between the U-shaped notches 2; when the distance is less than 10cm, the main bearings suspended side by side will be mutually extruded, resulting in the failure of access. Inconvenient; when the spacing is greater than 15cm, the number of main bearings that can be suspended simultaneously on the hanging plate 1 is reduced, resulting in a reduction in the practicability of the hanging plate 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com