Composite alloy plate and preparation method thereof

A composite alloy and alloy material technology, applied in the field of materials, can solve problems such as the inability to use a new multi-component foaming system, and achieve the effects of reducing the risk of cracking, improving the performance of foaming agent corrosion resistance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

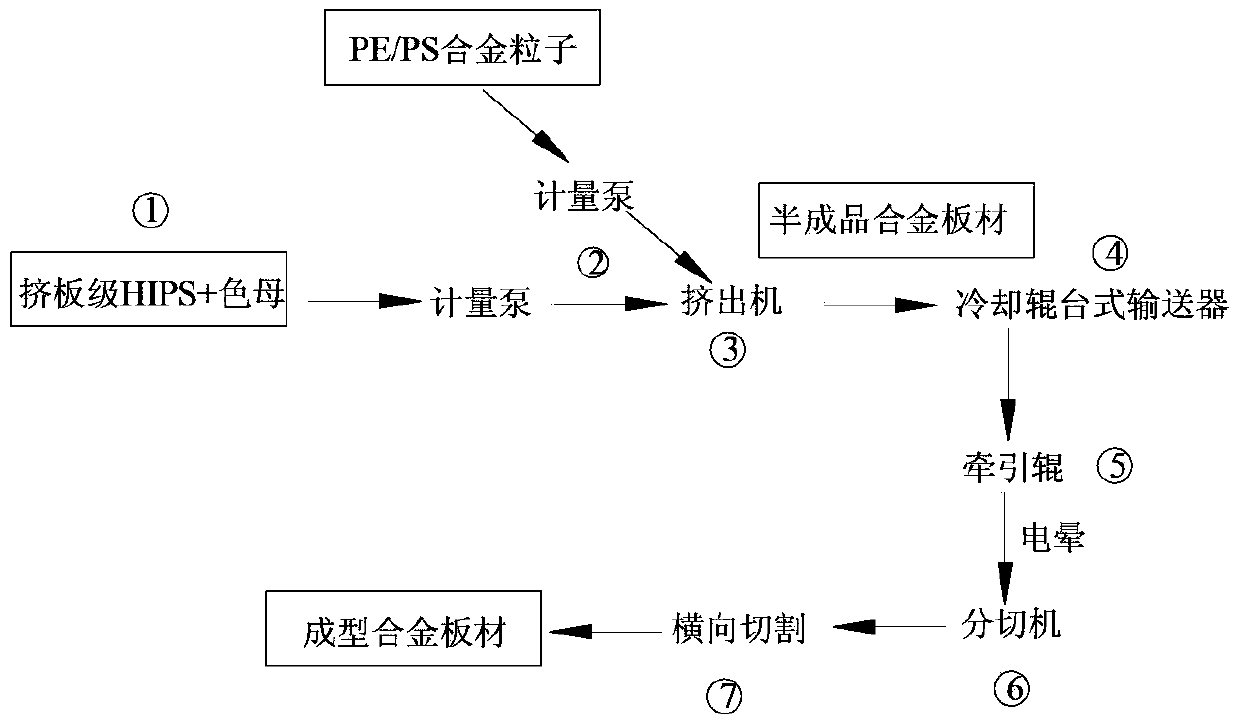

[0041] 1), according to figure 2 The process flow diagram shown prepares composite alloy door panels for double-layer co-extruded refrigerator / freezer linings. Firstly, the Chevron HIPS-D6007+ color masterbatch for extrusion-grade refrigerators is mixed evenly, and then mixed with PE / PS alloy material through a metering pump to adjust the addition of the two phases, and the semi-finished alloy plate is obtained by co-extrusion with an extruder.

[0042] 2) Temperature control at each stage: ② refers to the alloy plate forming area, and the temperature is controlled at 150-240°C; ③ refers to the extruder die, and the temperature of the head is generally controlled at 190-240°C; ④ Cooling roller desktop output device The temperature is controlled at 60-100°C, ⑤ refers to the traction roller, which plays the role of traction and forming, ⑥, ⑦ are to cut out the required specifications of the plate according to the requirements;

[0043] 3), the corona parameter is about 4.0×10 ...

Embodiment 2

[0047] 1), according to figure 2 The process flow diagram shown prepares composite alloy boxboard for double-layer co-extruded refrigerator / freezer lining. Firstly, the natural color extrusion-grade refrigerator special Xuestyron HIPS-1175+ color masterbatch is mixed evenly, and then the addition amount of the two phases is adjusted with the PE / PS alloy material through a metering pump, and the semi-finished alloy plate is obtained by co-extrusion with an extruder.

[0048] 2) Temperature control at each stage: ② refers to the alloy plate forming area, and the temperature is controlled at 150-240°C; ③ refers to the extruder die, and the temperature of the head is generally controlled at 190-240°C; ④ Cooling roller desktop output device The temperature is controlled at 60-100°C, ⑤ refers to the traction roller, which plays the role of traction and forming, ⑥, ⑦ are to cut out the required specifications of the plate according to the requirements;

[0049] 3), corona parameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com