Automatic marking machine

An automatic and hydraulic telescopic rod technology, used in typewriters, printing and other directions, can solve problems such as low production efficiency, injury to staff, threats to staff personal safety, etc., to achieve convenient operation, improve work efficiency, and save time and effort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

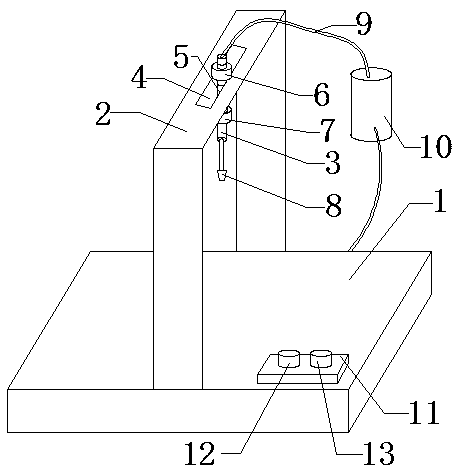

[0013] Such as figure 1 A kind of automatic marking machine shown, comprises base plate 1, support frame 2 and hydraulic telescopic rod 3; Described support frame 2 is fixed on the base plate 1; Described support frame 2 is provided with chute 4; The rod 3 is provided with a screw thread 5; the hydraulic telescopic rod 3 is fixed in the chute 4 through the upper screw cap 6 and the lower screw cap 7; the lower end of the hydraulic telescopic rod 3 is provided with a marking head 8; The hydraulic telescopic rod 3 is connected to a hydraulic pump 10 through a pipeline 9; a control circuit (not shown) is provided inside the base plate 1; a control button group 11 is provided on the upper surface of the base plate 1; the hydraulic pump 10 and the control The button groups 11 are all connected to the control circuit (not shown) through wires.

[0014] Wherein, the support frame 2 is in the shape of "concave"; the hydraulic pump 10 is a quantitative hydraulic pump; the cont...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap