Automatic inductive type trash can

An automatic induction, trash can technology, applied in the field of sanitary products, can solve the problems of not being able to remind the trash can in time, reducing the practicability, unable to know the trash can liquid in advance, etc. Longevity, Conspicuous Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

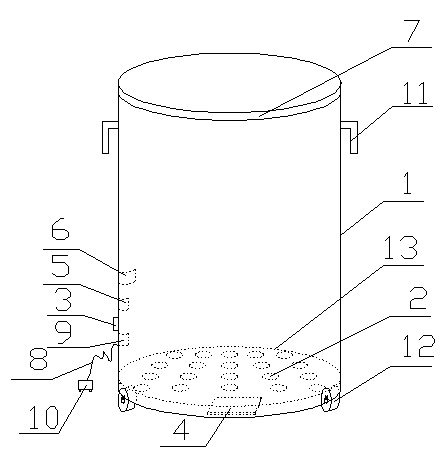

[0014] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0015] Such as figure 1 As shown, the present invention provides an automatic induction trash can, which includes a barrel body 1 and an induction device arranged on the barrel body 1, the induction device includes a battery 9, a switch 3, a humidity sensor 4, and a battery connected in sequence. Analog-to-digital converter 5, processor 6, LED lamp 7, wherein humidity sensor 4 is arranged on the bottom wall of staving 1; The bottom of described staving 1 is provided with barrier layer 13, on described barrier layer 13 The leak hole 2 is uniformly arranged; the humidity sensor 4 is used to detect the liquid leaked from the leak hole 2 and obtain an analog signal, which is converted by the analog-to-digital converter 5 and transmitted to the processor 6; the processor 6 controls the LED lamp 7 Lights up to indicate.

[0016] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com