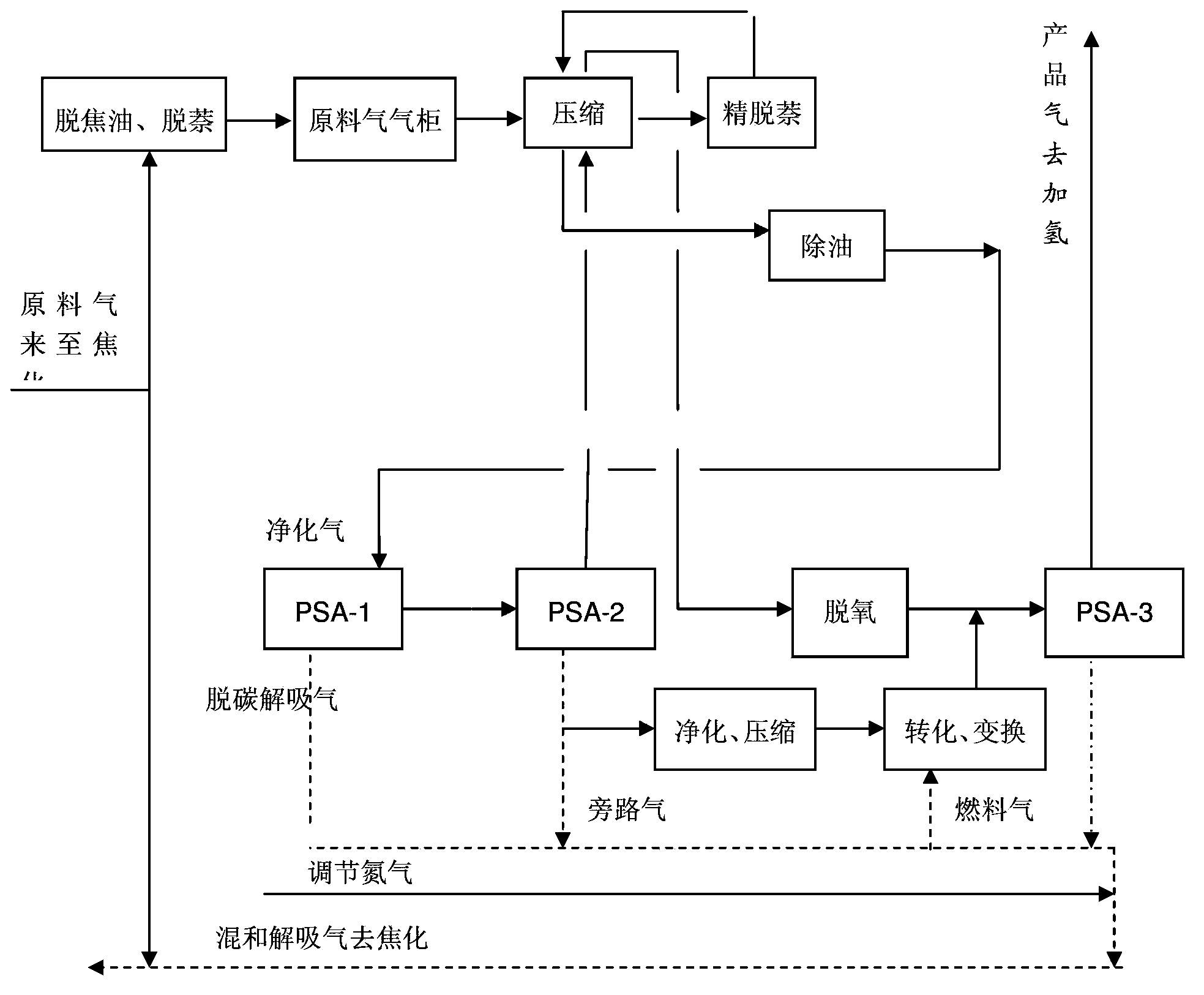

Coke oven gas hydrogen generation process

A coke oven gas and process technology, applied in the field of coke oven gas hydrogen production process, can solve the problems of high purity requirements, high power consumption, high production and operation costs, and achieve the effects of flexible process adjustment, reduced exhaust gas emissions, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] 1. Using the high-efficiency coal coking process of the Second Design Institute of Chemical Industry, the coal coking time is short, the gas production is large, and the gas output is 1.5 times more than the traditional process.

[0023] 2. Coke oven gas hydrogen production process:

[0024] (1) Pre-purification process: coke oven gas enters the pre-purification process at a temperature of 40°C. This process consists of 5 fine denaphthalene removers, 1 electric heater and a series of manual valves.

[0025] Utilizing the strong adsorption of coke, it enters the crude denaphthalene system consisting of 5 crude denaphthalenizers for treatment, the gas enters from the bottom to the top, and the impurities that come out are deposited at the bottom and removed by leaching. The superheated steam with a temperature of about 400°C and a pressure of 0.2MPa heats the oil and naphthalene removal device to regenerate it. After the pre-purification system, most of the tar, naphthal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap