A three-dimensional ordered macroporous-mesoporous metal oxide or composite oxide gas phase infiltration-precipitation preparation method and the resulting product

A composite oxide, three-dimensional ordered technology, applied in the field of synthesis of nano-micro functional materials, can solve the problems of easy collapse of macroporous structure, and achieve the effects of reducing environmental hazards, simple structure, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

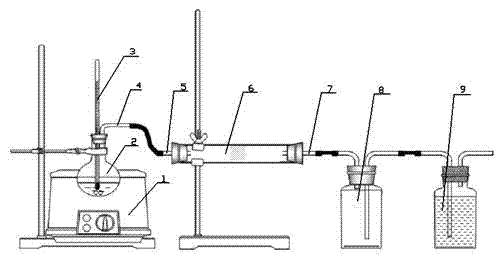

Method used

Image

Examples

Embodiment 1

[0057] At normal temperature and pressure, 0.7237 g Ce(NO 3 ) 3 ·6H 2 O, 1.9999 g Ti(SO 4 ) 2 , 2.1014 g citric acid and 1 g P123 dissolved in 10 g H 2 O, after mixing evenly, 5 g PMMA was added to the above solution, after soaking for 3 h, the excess precursor solution was removed by vacuum filtration, and the filtered sample was at 20 o C was dried for 2 h, and the dried sample was transferred to the gas phase osmosis-precipitation device, at 40 o C was reacted for 2 h, and the precipitated sample was o C and dried for 24 h, put the obtained solid into a porcelain boat and place it in a tube furnace, and use a two-step roasting method to firstly bake it with 1 o C / min rate of heating up to 300 o C and keep at this temperature for 3 h, after cooling down to room temperature, add 1 o C / min rate of heating up to 500 o C and kept at this temperature for 6 h, a three-dimensional ordered macroporous-mesoporous Ce-Ti composite oxide with a Ce / Ti molar ratio of 0.2 w...

Embodiment 2

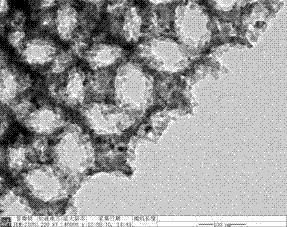

[0059] At normal temperature and pressure, 1.9976 g Ce(NO 3 ) 3 ·6H 2 O, 3.6962 g Ti(SO 4 ) 2 , 2.1014 g citric acid and 1.5 g P123 dissolved in 10 g H 2 O, after mixing evenly, add 5 g PMMA to the above solution, soak for 3 h and completely infiltrate, then remove excess precursor solution by vacuum filtration; o C for 2 h, the dried sample was transferred to the gas phase osmosis-precipitation device, at 50 o C was reacted for 3 h, and the sample after precipitation was o C and dried for 24 h, put the obtained solid into a porcelain boat and put it in a tube furnace, and adopt a one-step roasting method in the air atmosphere (50 mL / min) at 1 o C / min rate of heating up to 300 o C and keep at this temperature for 3 h, then continue with 1 o C / min rate of heating up to 550 o C and kept at this temperature for 6 h, a three-dimensional ordered macroporous-mesoporous Ce-Ti composite oxide with a Ce / Ti molar ratio of 0.3 was prepared, and its TEM image is shown in i...

Embodiment 3

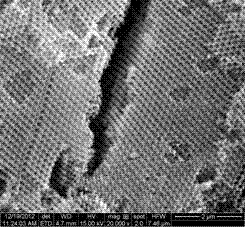

[0061] The operation is the same as in Example 2, except that ammonia water (25-28 wt%) is added dropwise to the dried sample to precipitate the metal salt between the templates, and the excess ammonia water is removed by filtration, and the obtained product is dried again, and the two-step roasting method is adopted. A composite oxide with a Ce / Ti molar ratio of 0.3 is obtained, and its SEM image is shown in Figure 4 It can be seen from the SEM image that although the structured Ce-Ti composite oxide has a macroporous structure, the order of the pore structure is poor, and some macroporous structures collapse, resulting in many granular products. Therefore, the Ce-Ti composite oxide prepared by using ammonia water as a curing agent does not have a large-scale three-dimensional ordered macroporous structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com