A photocatalytic self-healing superhydrophobic coating and its preparation method

A technology of super-hydrophobic coatings and super-hydrophobic coatings, applied in the direction of polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of no self-healing, super-hydrophobic performance, etc., and achieve simple preparation process and recovery Super-hydrophobic performance, the effect of ensuring long-term serviceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

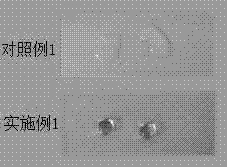

Embodiment 1

[0043] 1) Mix 30 parts of hydrophilic SiO 2 Disperse the nanoparticles in 600 parts of ethanol, then add 3.0 parts of ammonia water and 3.2 parts of heptadecafluorodecyltrimethoxysilane, mix well and then react at 60°C for 24 hours, wash and dry to obtain hydrophobic nano-SiO 2 .

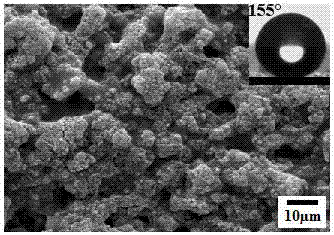

[0044] 2) Add 0.53 parts of BYK182 dispersant, 0.38 parts of BYK306 leveling agent and 0.32 parts of BYK052 defoamer to 100 parts of butyl acetate, and after shearing and dispersing for 10 minutes, the hydrophobic nano-SiO obtained in step 1) 2 and 6 parts of photocatalytic TiO 2 Nanoparticles were added to 100 parts of butyl acetate, and sheared and dispersed for 10 minutes; then 40 parts of polystyrene, 19 parts of fluorine-containing hydroxypropyl silicone oil (molecular weight 8000g / mol) and 10 parts of dodecafluoroheptylpropyl trimethyl The oxysilane was added to the above dispersion liquid, and sheared and dispersed for 2 hours to obtain a nanocomposite coating. Spray the prepared coating o...

Embodiment 2

[0047] 1) Add 30 parts of Fe 3 o 4 Disperse the nanoparticles in 600 parts of ethanol, then add 4 parts of ammonia water and 3.8 parts of dodecafluoroheptylpropyltrimethoxysilane, mix well and then react at 65°C for 22 hours, wash and dry to obtain hydrophobic nano-Fe 3 o 4 .

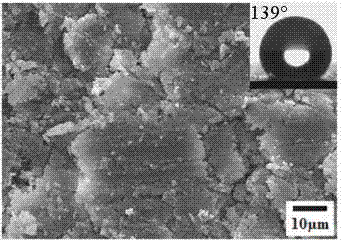

[0048] 2) Add 0.50 parts of Deqian 903 dispersant, 0.35 parts of Deqian 435 leveling agent and 0.30 parts of Deqian 3100 defoamer to 100 parts of xylene, and shear and disperse for 10 minutes. Fe 3 o 4 and 7.5 parts of ZnO nanoparticles were added to 120 parts of xylene, sheared and dispersed for 10 minutes; then 35 parts of polymethyl methacrylate, 25 parts of fluorine-containing vinyl silicone oil (molecular weight 7000g / mol) and 8 parts of heptadecafluoro Add decyltrimethoxysilane to the above dispersion liquid, and shear and disperse for 2 hours to prepare a nanocomposite coating. The prepared paint roller is coated on the tinplate, and dried at 100°C for 10 minutes to obtain a super-hydrophob...

Embodiment 3

[0050] 1) Add 30 parts of Al 2 o 3 Nanoparticles are dispersed in 600 parts of ethanol, then 3.5 parts of ammonia water and 3.5 parts of tridecafluorooctyltrimethoxysilane are added, mixed evenly and then reacted at 75°C for 18 hours, washed and dried to obtain hydrophobic nano-Al 2 o 3 .

[0051] 2) Add 0.50 parts of EFKA-4061 dispersant, 0.38 parts of CN322 leveling agent and 0.35 parts of Deqian 6800 defoamer to 100 parts of acetone, and after 10 minutes of shear dispersion, the hydrophobic nano-Al 2 o 3 and 8 parts of ZnS nanoparticles were added to 90 parts of acetone, and sheared and dispersed for 10 minutes; then 42 parts of polyurethane, 18 parts of fluorine-containing hydroxypropyl silicone oil (molecular weight 8500g / mol) and 9 parts of heptadecafluorodecyltrimethoxy The silane was added to the above dispersion liquid, and sheared and dispersed for 2 hours to obtain a nanocomposite coating. Brush the prepared paint onto tinplate, and dry it at 60°C for 10 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com