Steel forging with ultra-high strength and ultra-high low-temperature impact on box body of fracturing pump valve and manufacturing method of steel forging

A low-temperature impact and ultra-high-strength technology, which is applied in the field of ultra-high-strength ultra-high and low-temperature impact fracturing pump valve box steel forgings and its manufacturing field, can solve the problems that cannot meet the normal use in alpine regions, the mechanical properties of materials are not strong, and the service life Short and other problems, to improve the ability to resist intergranular corrosion, improve anti-oxidation and acid resistance, and improve the effect of as-cast structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 5 example

[0047] 1. Steelmaking:

[0048] Select conventional raw materials, and through the steps of electric arc furnace smelting-extra-furnace refining-vacuum degassing-casting electrode billet-electroslag remelting-diffusion annealing, the raw materials are made into steel ingots with the chemical composition shown in Table 1. The steel ingots with this chemical composition meet the requirements of "C≤0.30, Si: 0.15--0.35, Mn: 0.6--0.9, S≤0.010, P≤0.010, Cr: 1.80-2.20, Ni>4.00, Mo>0.45, V: 0.12-0.18, Cu≤0.20, Nb, Re: appropriate amount, H≤1.6ppm, 0≤35ppm, N≤65ppm" requirements.

[0049] 2. Inspection:

[0050] Full composition analysis, metallographic inspection and ultrasonic non-destructive testing are carried out on electroslag remelted steel ingots, and steel ingots with qualified quality indicators such as material composition, inclusions and non-destructive testing are screened out.

[0051] The specific process is to first conduct a full analysis of the chemical composition...

no. 6 example

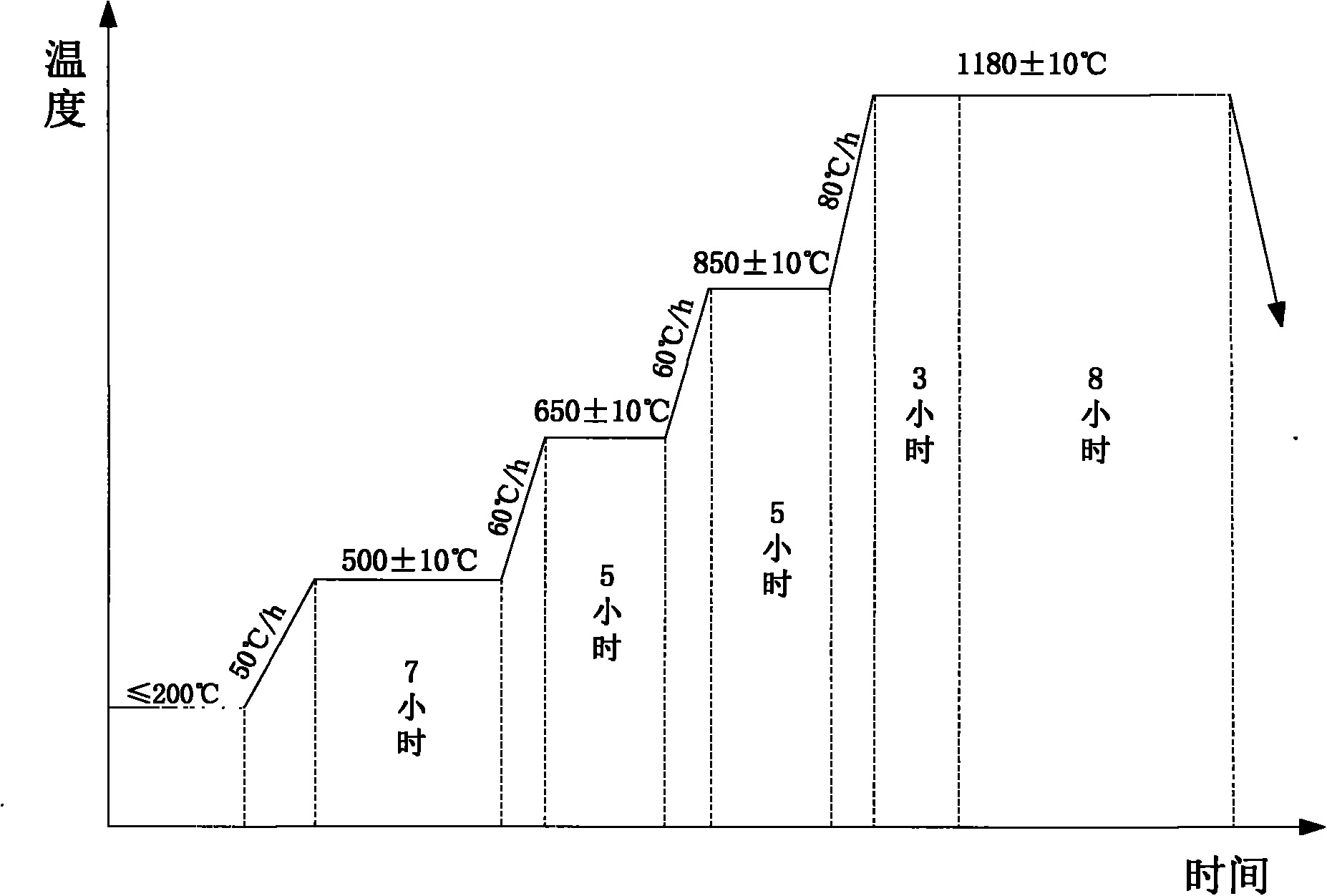

[0083] The implementation of this embodiment is the same as that of the fifth embodiment, wherein in the third step heating and heat preservation process, heat and heat preservation is carried out according to the three-stage heating method. Keep the steel ingot at a temperature of 510°C for 7 hours, then raise the temperature at a rate of 60°C / h to 660°C and hold it for 5 hours, then increase the rate of temperature at 60°C / h to 860°C and hold it for 5 hours, then heat it at 80°C The heating rate is raised to 1190°C for 3 hours at a rate of 1 / h, and finally kept at 1190°C for 8 hours.

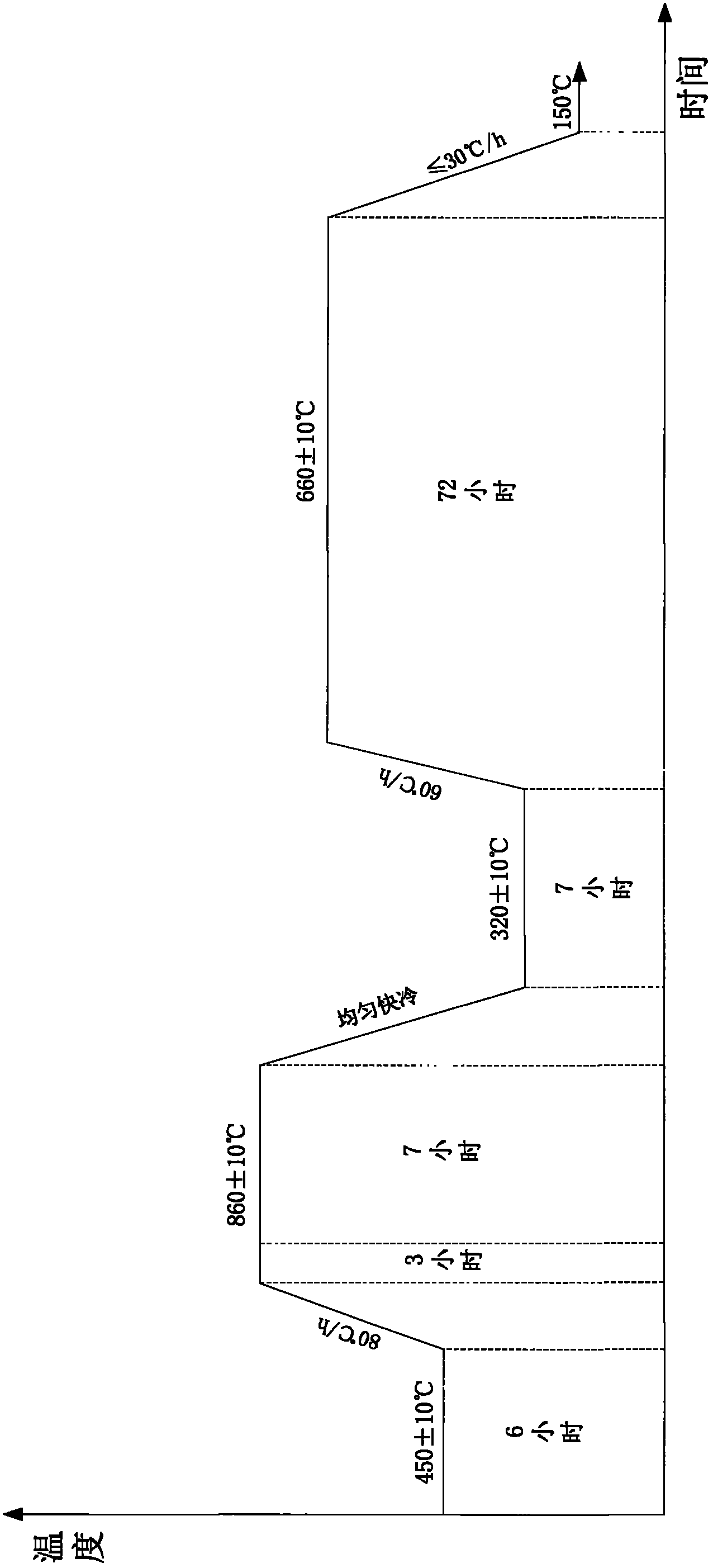

[0084]In the fifth step, in the post-forging heat treatment process, the first step is to blast and cool the forgings with a final forging temperature > 850°C to 450°C outside the furnace; the second step is to put the forgings into the heating furnace at 460°C. ℃ for 6 hours; the third step is to raise the furnace temperature to 870 ℃ at a heating rate of 80 ℃ / h for 3 hours, and keep the temp...

no. 7 example

[0086] The implementation of this embodiment is the same as that of the fifth embodiment, wherein in the third step heating and heat preservation process, heat and heat preservation is carried out according to the three-stage heating method. Keep the steel ingot at 500°C for 7 hours, then raise the temperature to 650°C at a rate of 60°C / h and hold it for 5 hours, then raise it to 850°C at a rate of 60°C / h and hold it for 5 hours, and then increase the temperature at 80°C / h The heating rate of h increased to 1180°C for 3h, and finally kept at 1180°C for 8h.

[0087] In the fifth step, in the post-forging heat treatment process, the first step is to blast and cool the forgings with a final forging temperature > 850°C to 450°C outside the furnace; the second step is to put the forgings into the heating furnace at 450°C ℃ for 6 hours; the third step is to raise the furnace temperature to 860 ℃ at a heating rate of 80 ℃ / h for 3 hours, and keep the temperature for 7 hours; the fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com