Wind driven generator

A technology for wind turbines and wind turbines, applied in wind turbines, wind energy power generation, wind turbine control, etc., can solve the problems of lack of circuit protection, rising costs, etc., and achieve strong economic applicability, load reduction, and total output power reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

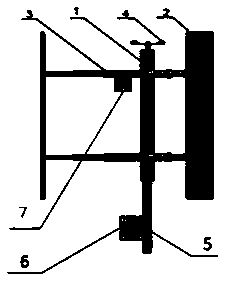

[0048] figure 1 It is the front view of the wind power generator involved in the present invention before the typhoon comes in the first embodiment;

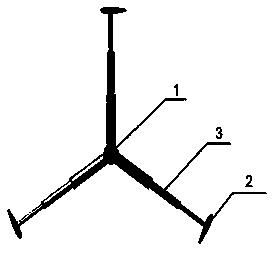

[0049] figure 2 It is a top view of the wind power generator involved in the present invention before the typhoon comes in Embodiment 1;

[0050] Such as figure 1 , 2 As shown, the wind power generator involved in the present invention includes: a pillar 5 fixed on the ground, a rotating shaft 1 fixed on the pillar and a wind wheel assembly rotating in a horizontal plane around the rotating shaft. The wind wheel assembly includes three rotating parts, and the rotating part Consists of: blades 2 and length-adjustable rods 3 . One end of the rod 3 is fixed to the rotating shaft 1, and the other end is fixed to the blade 2, and each blade is fixed by two rods;

[0051] The wind power generator involved in the present invention further includes: a driving device 7 , an anemometer 4 and a control device 6 . The driving device ...

Embodiment approach 2

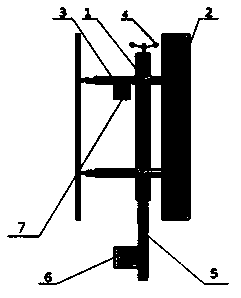

[0068] Image 6 It is the front view of the wind power generator involved in the present invention before the typhoon comes in the second embodiment;

[0069] Figure 7 It is the top view of the wind power generator involved in the present invention before the typhoon comes in the second embodiment;

[0070] Such as Image 6 , 7 Shown: the wind power generator that the present invention relates to comprises: the pillar 5 that is fixed on the ground, the rotating shaft assembly that is fixed on the pillar and the wind wheel assembly that rotates around the rotating shaft in the horizontal plane, and the wind wheel assembly includes at least two elastic The blade 2, a rod 3 with an adjustable length; the shaft assembly includes a shaft 1, a fixed block 7 and a fixed block 8. The blade 2 is arc-shaped in the vertical plane; one end of the blade 2 is fixed on the fixed block 7, and the fixed block 7 is fixed to the lower end of the rotating shaft 1; the other end of the blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com