Buffer tank structure for natural gas compressor

A buffer tank and compressor technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of discontinuity, affecting the normal production and production personnel safety of natural gas compressors, cracks, etc., to simplify the stress , the effect of prolonging the time of fatigue failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

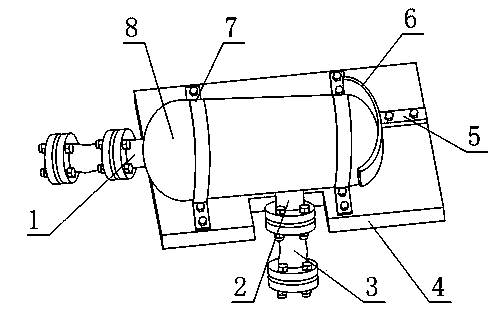

[0024] Such as figure 1 As shown, the buffer tank structure for natural gas compressors includes a buffer tank 8, an air outlet pipe 1 and an air inlet pipe 2. The buffer tank 8 is fixedly connected by a cylinder in the middle and heads at both ends. The air outlet pipe 1 It is fixedly connected to any head, the air inlet pipe 2 is fixedly connected to the cylinder body, and also includes a support plate 4 and two flexible pipes 3, and the two flexible pipes 3 are fixedly connected to the air outlet pipe 1 and the air inlet pipe 2 respectively , the support plate 4 is located below the buffer tank 8 , and the support plate 4 is fixedly connected to the buffer tank 8 .

[0025] The two flexible pipes 3 are set so that the buffer tank 8 is flexibly connected to the gas outlet of the upper stage and the inlet end of the next stage, so that the uneven exhaust of the upper stage and the uneven suction of the lower stage cause the buffer tank 8 to Most of the gas column resonance a...

Embodiment 2

[0027] The present embodiment is further limited on the basis of embodiment 1, as figure 1 As shown, at least two hoop bodies 7 are also included, and the buffer tank 8 is fixedly connected to the support plate 4 through the hoop bodies 7 .

[0028] The support plate 4 and the buffer tank 8 are connected in the form of a hoop, so that the contact area between the hoop body 7 and the buffer tank 8 is large, which is beneficial to reduce the degree of stress concentration of the interaction force between the buffer tank 8 and the support plate 4 .

[0029] It also includes an arc-shaped plate 6, which is fixedly connected with the support plate 4, and the arc-shaped plate 6 is in contact with the outer wall surface of the head opposite to the head connected with the air outlet pipe 1.

[0030] The provided arc plate 6 is used to counteract the recoil force of the gas discharged from the buffer tank 8 , which is beneficial to the stability of the buffer tank 8 fixed on the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com