Structure for fixing car pipeline

A technology for fixing structures and automobile pipelines. It is applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of inability to reduce noise, poor reliability, and inability to buffer and absorb shocks, so as to improve stability and safety. , Accurate installation and positioning, good energy absorption and shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

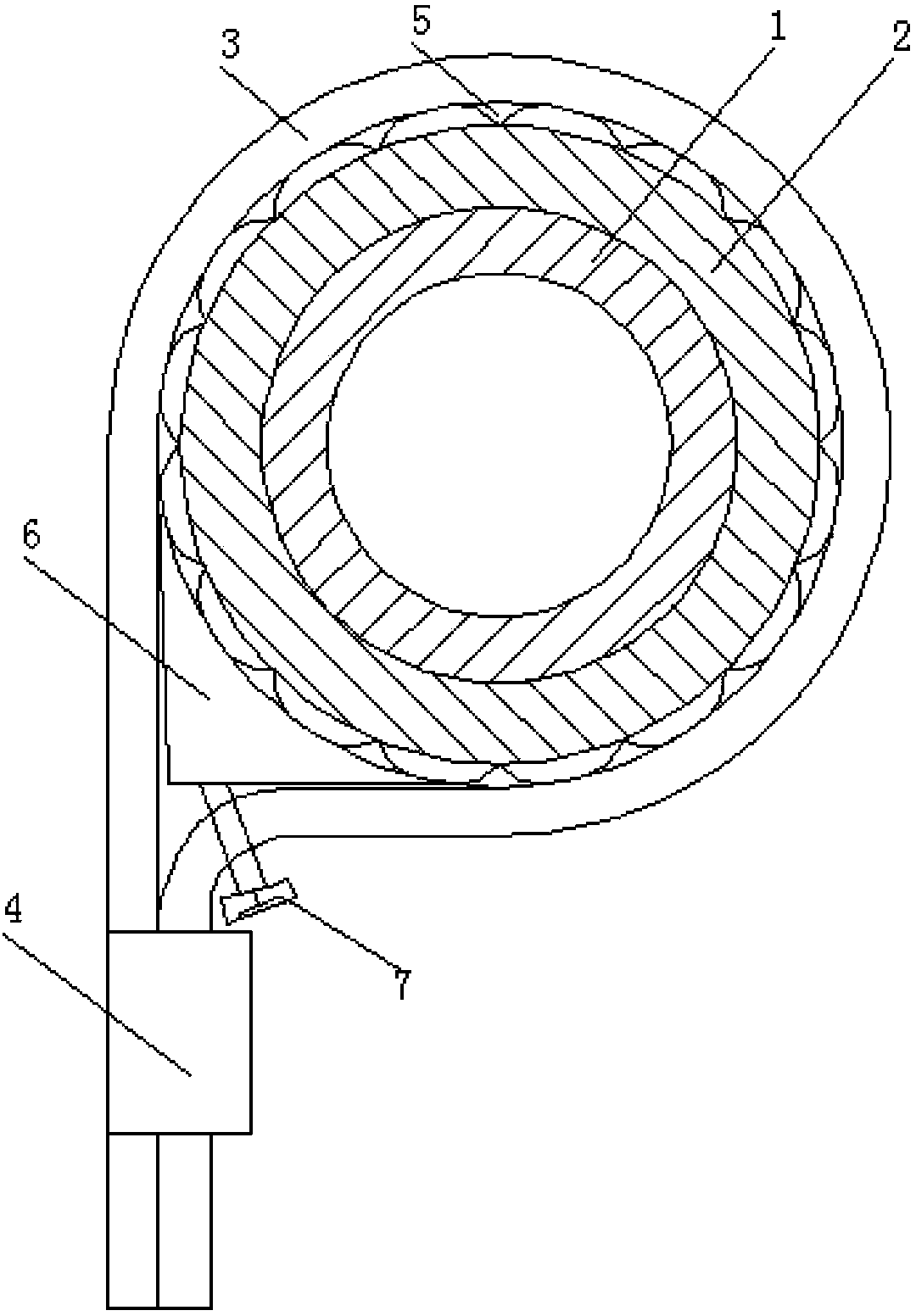

[0011] Such as figure 1 As shown, the automobile pipeline fixing structure includes an automobile oil pipe 1, and the automobile oil pipe 1 is covered with a cushion layer 2. The cushion layer 2 is a shock absorbing and energy-absorbing cushion layer, and the cushion layer 2 is surrounded by a metal connecting piece 3. It is fixed by the lug 4 on the metal connecting piece, and the part of the inner wall where the metal connecting piece 3 is connected to the pad 2 is provided with a fastening and stabilizing structure.

[0012] Wherein, the fastening and stabilizing structure is evenly arranged ridge-shaped protrusions 5 .

[0013] Wherein, there is a gap between the metal connecting piece 3 and the cushion layer 2 after being fixed, and a reinforcing block 6 is arranged in the gap, and the reinforcing block is also provided with a protrusion, and an adjusting screw 7 is provided on the connecting piece to extend into the gap and connect with the reinforcing block .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap