Energy-saving and environment-friendly heating furnace with gasification barrel

An energy-saving and environmental protection technology for heating stoves, which is applied to stoves/stoves with hot water devices, combustion air/flue gas circulation of stoves, household stoves/stoves, etc. , inability to enter the furnace cavity, etc., to avoid insufficient air intake, improve energy utilization, and reduce smoke and dust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

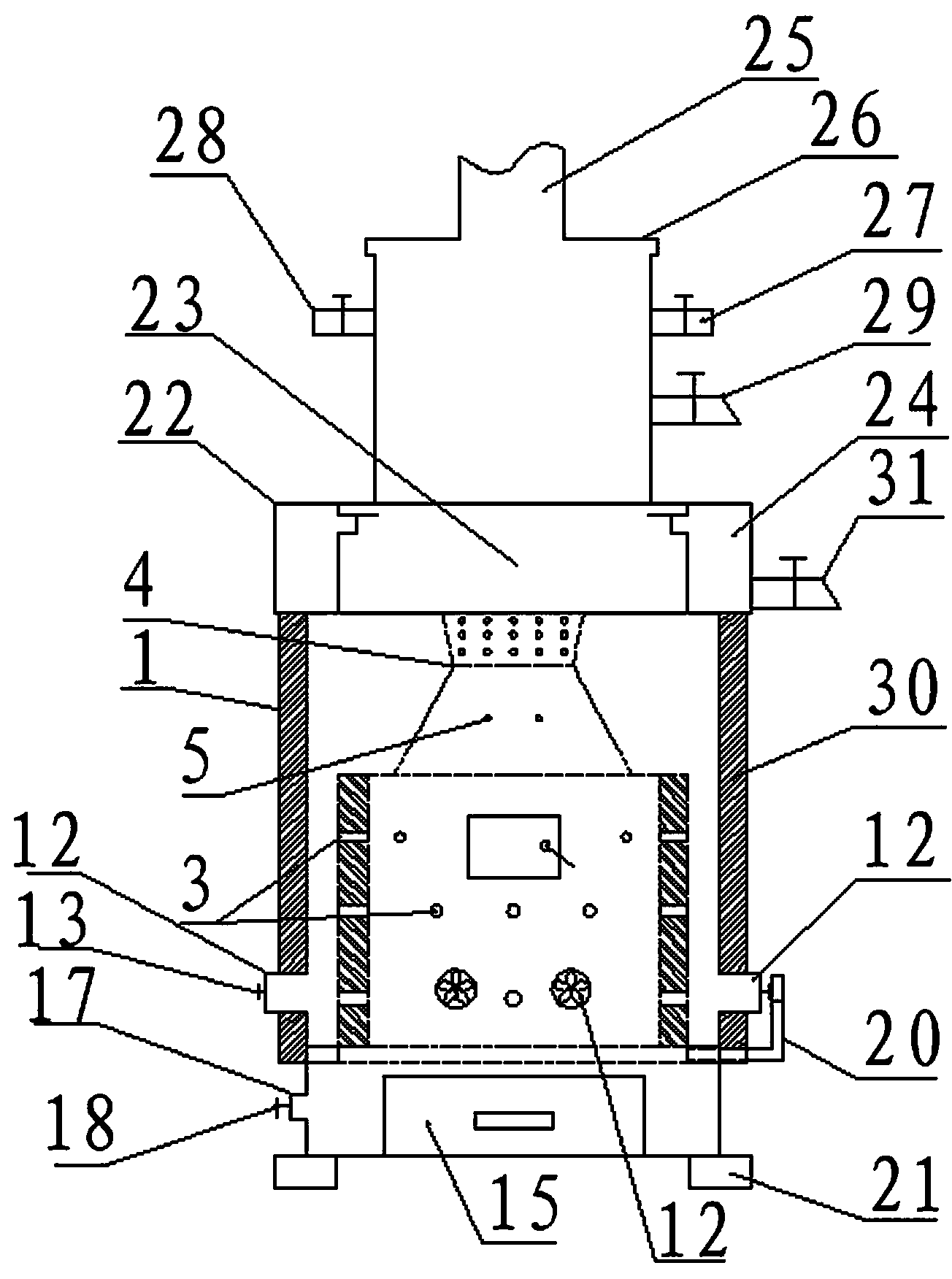

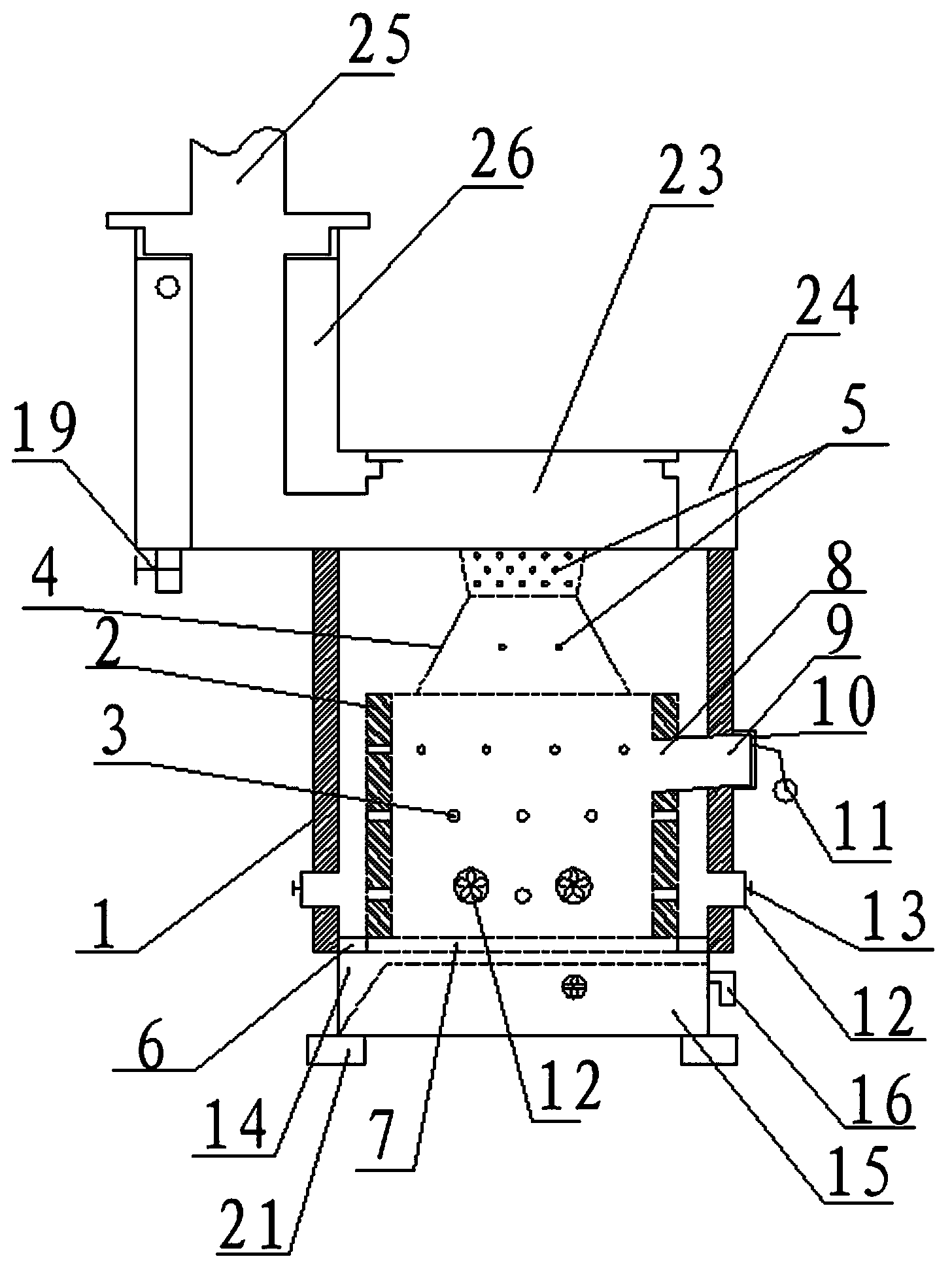

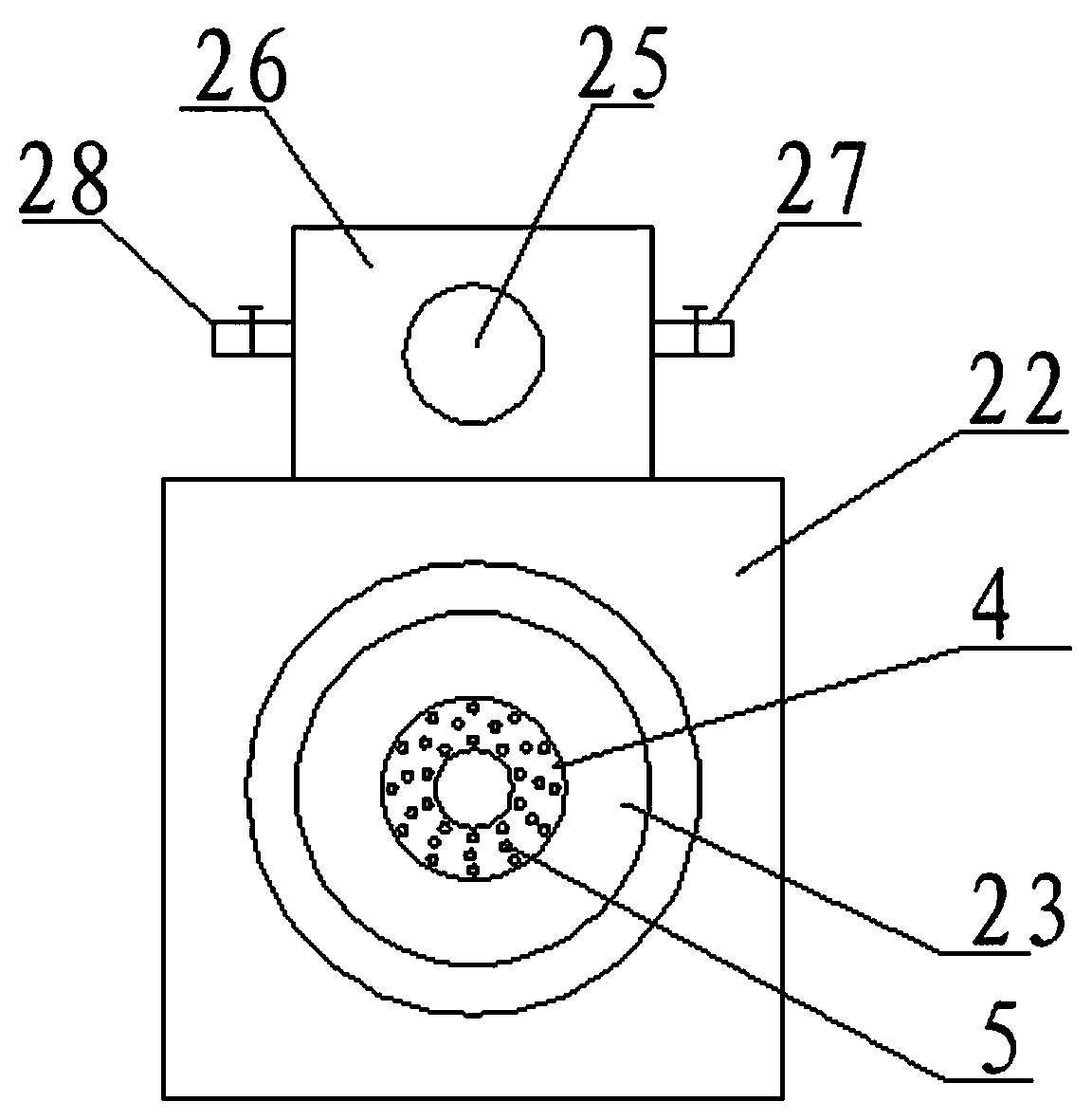

[0024]Embodiment: An energy-saving and environment-friendly heating furnace with a gasification cylinder, including a furnace body 1 and a furnace core 2. The furnace core 2 is provided with a combustion-supporting hole I3, and the combustion-supporting hole I3 is divided into three rows. There are four combustion-supporting holes Ⅰ3 with a diameter of Φ14mm and a distance of 60mm from the top of the bottom furnace bridge 7. There are twelve combustion-supporting holes Ⅰ3 in the middle row with a diameter of Φ12mm and a distance of 100mm from the top of the bottom furnace bridge 7. There are eight rows of combustion-supporting holes I3, the diameter of which is Φ12mm, and the distance from the top of the bottom furnace bridge 7 is 200mm. The upper opening of the furnace core 2 is provided with a gasification cylinder 4, and the gasification cylinder 4 is provided with a combustion-supporting hole II5. 4 The apertures at both ends are larger, the aperture in the middle is smalle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com