Metal electrification shearing test device and test method

A shear test, metal technology, applied in the direction of using a stable shear force to test the strength of materials, can solve the problems of non-vertical shear section, unable to meet the requirements of electricity, achieve good insulation effect, avoid coating aging and falling off Defects, effect of ensuring insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

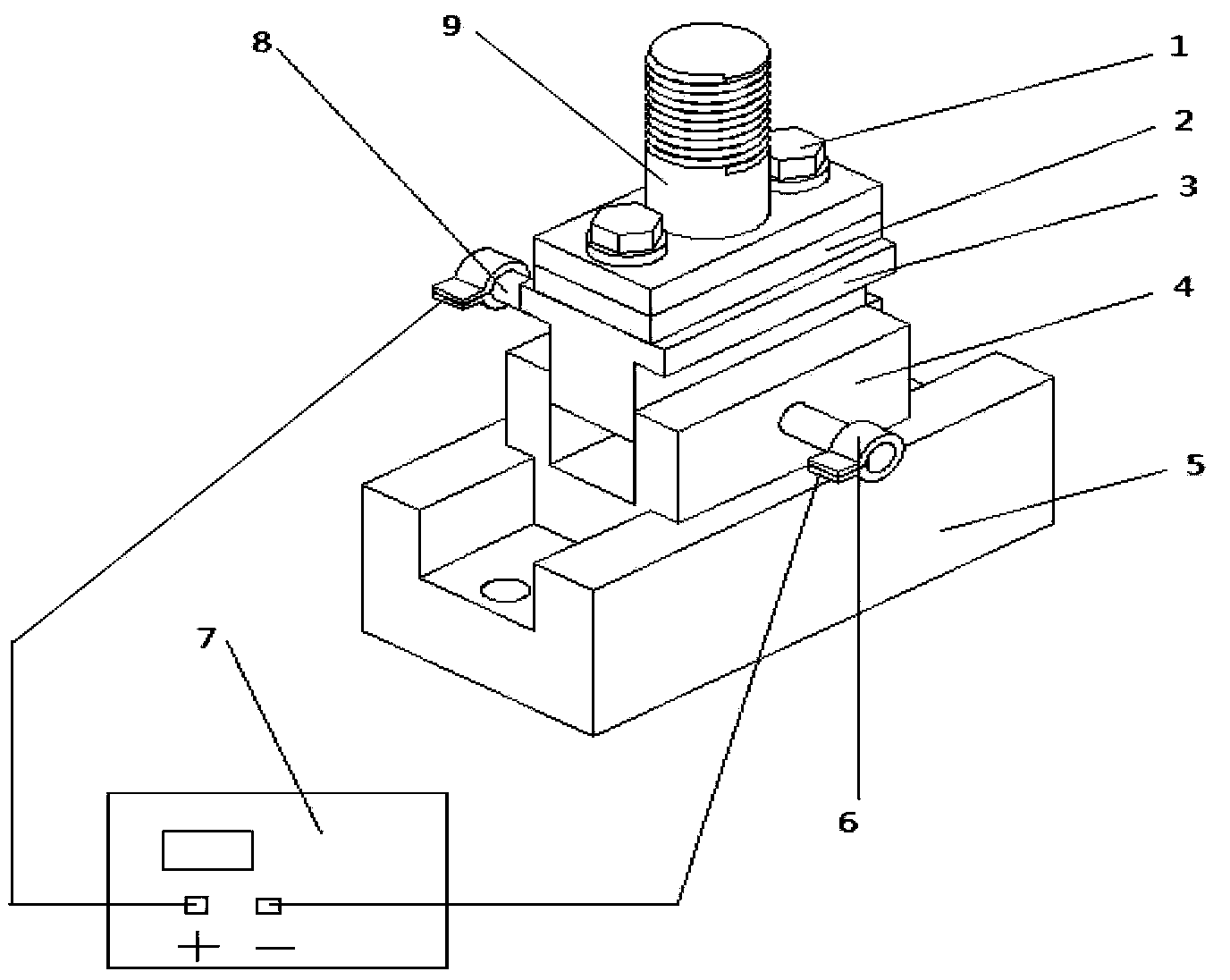

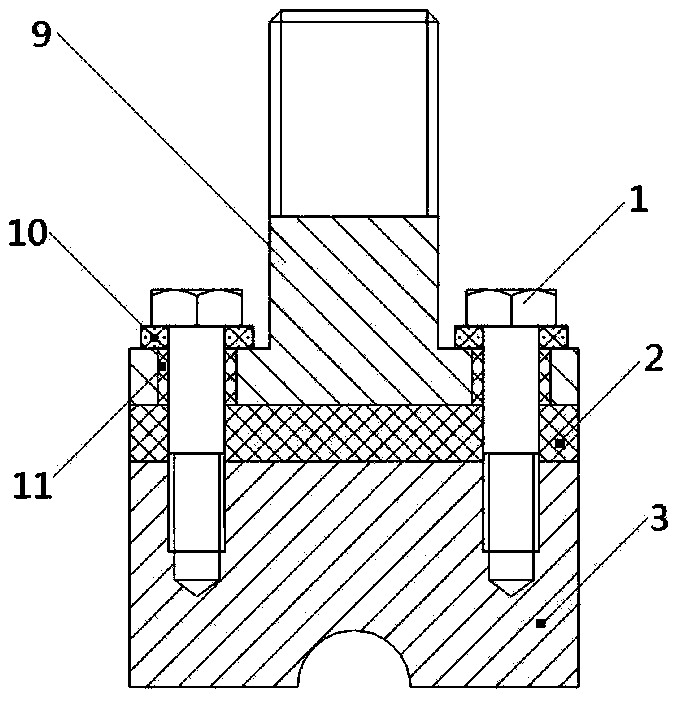

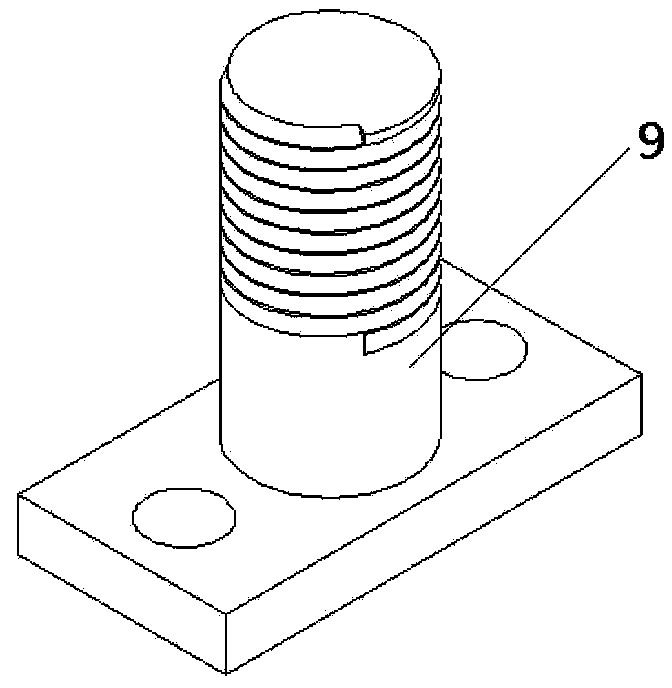

[0023] This embodiment is a metal energized shear test device and test method. The shear section of the material shear sample is cut by radial compression loading to measure the shear strength. In order to reduce the stress concentration during the shear process and make the experimental results more accurate, the die shear edge adopts a circular shape. The double-shear test method in which the notch replaces the semicircular notch is used. The test device is assembled according to the assembly sequence, the wire of the high-energy pulse power supply is connected to the shear sample, the electronic universal testing machine is adjusted, and the high-energy pulse power supply is connected to carry out the test. In the energized shear test, after the sample is cut, record the maximum test load P during the shear test, according to the formula τ b =P(2S) calculates the shear strength.

[0024] refer to Figure 1-Figure 7 , the present embodiment is used for a length of 120mm, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com