Interface tension measuring device and method by hanging drop or bubble blowing way under high pressure

An interfacial tension and measuring device technology, applied in the direction of surface tension analysis, etc., can solve the problems of temperature control and the inability to switch quickly between the two measurement methods, and cannot withstand high pressure, etc., to achieve easy operation, controllable and measurable pressure, accurate measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

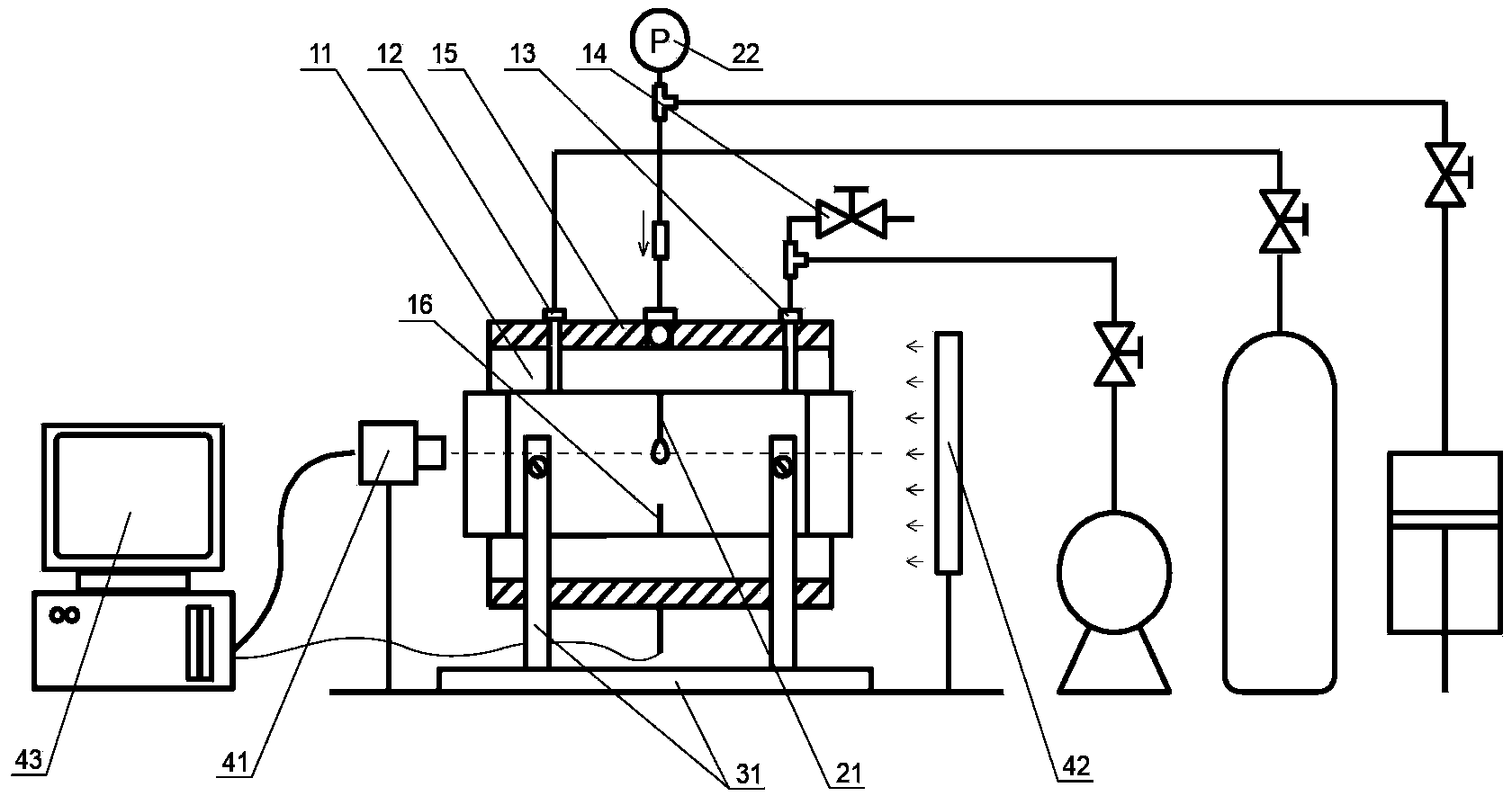

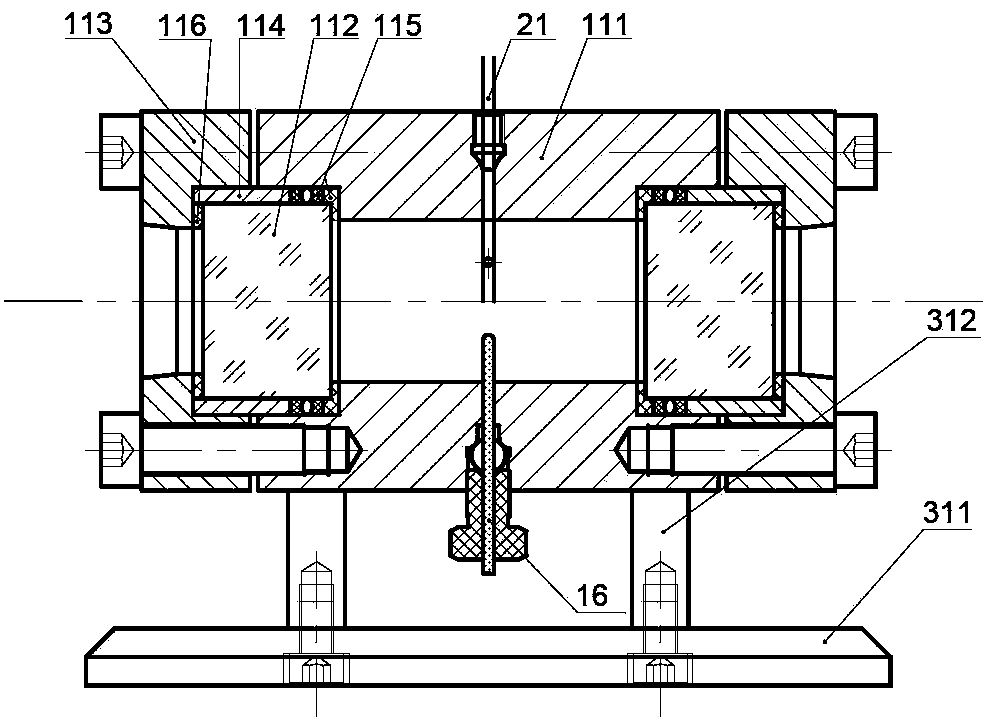

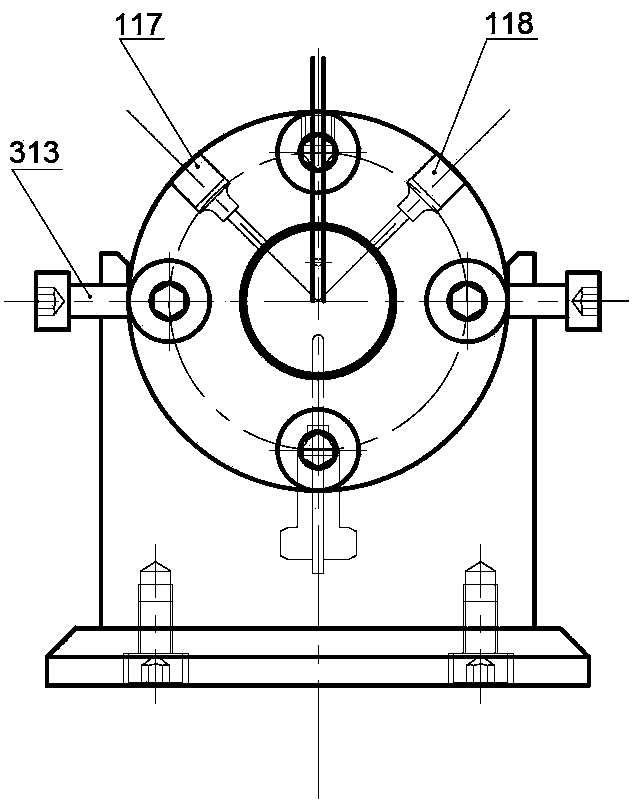

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0022] Taking the droplet method to measure the interfacial tension as an example, combined with figure 1 , Fig. 2 (a), Fig. 2 (b) further illustrate the working process of the present invention as:

[0023] Place the metal window pressure chamber 11 on the support frame 312 and adjust its position so that the thin injection tube 21 is in a position perpendicular to the horizontal plane, and then tighten the locking bolt 313 . Adjust the depth of the injection thin tube 21 inserted into the metal window pressure chamber 11, turn on the backlight 42 and open the camera software on the data processing computer 43, observe through the CCD camera 41, when the outlet end face of the injection thin tube 21 is in the center of the window of the CCD camera 41 When locking the injection capillary 21 with an adjustable ferru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com