Steel tube broadband magnet yoke flaw detection method and apparatus thereof

A technology of flaw detection and magnetic yoke, which is applied in the direction of material magnetic variables, etc., to achieve high work efficiency, high precision and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

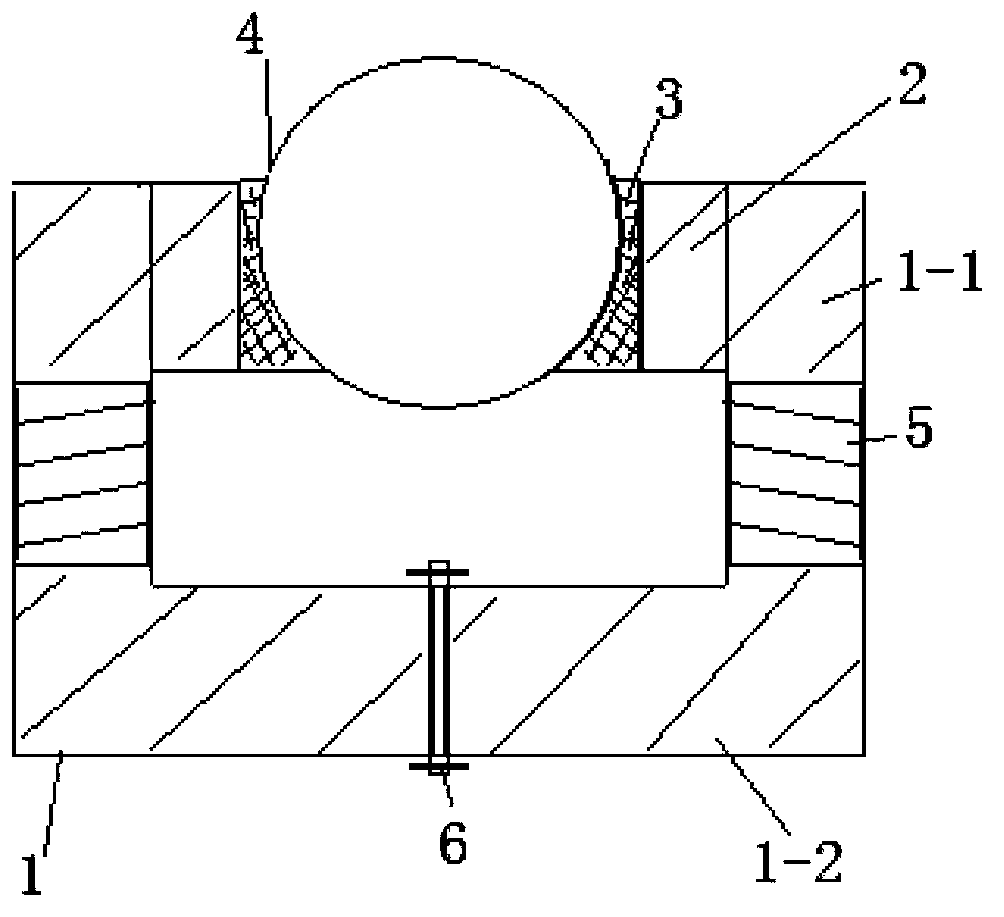

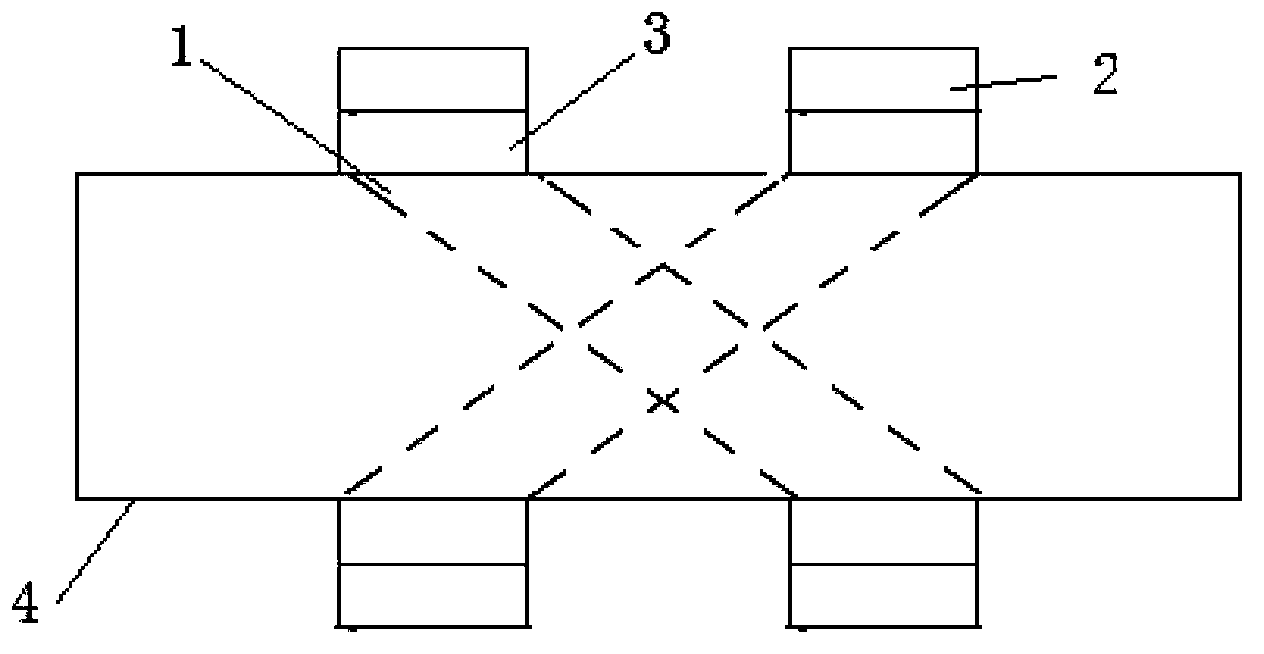

[0014] As shown in the figure, the magnetic yoke includes U-shaped main iron core 1, guide iron core 2, magnetic rubber 3, steel pipe 4, coil 5, vertical section 1-1 of U-shaped main iron core, and horizontal section of U-shaped main iron core. Section 1-2, connecting piece 6.

[0015] A steel pipe broadband magnetic yoke flaw detection method, the magnetization unit flows an alternating current as an excitation current and applies it to the yoke, the yoke is in contact with the steel pipe surface, the magnetized area of the steel pipe is sprayed by a magnetic powder liquid sprayer, and the image acquisition device sprays the magnetic powder on the steel pipe. The image acquisition device includes a camera and a light source; the light source is an ultraviolet lamp. Including the magnetization unit, the magnetization unit includes a magnetization power supply and a yoke, and the yoke includes a U-shaped main iron core, a guide iron core, and the difference between the cross-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com